Device for cleaning a spray gun

A technology of equipment and spray gun, which is applied in the equipment field of cleaning spray gun, and can solve the problem that the cleaning equipment cannot be reliably positioned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

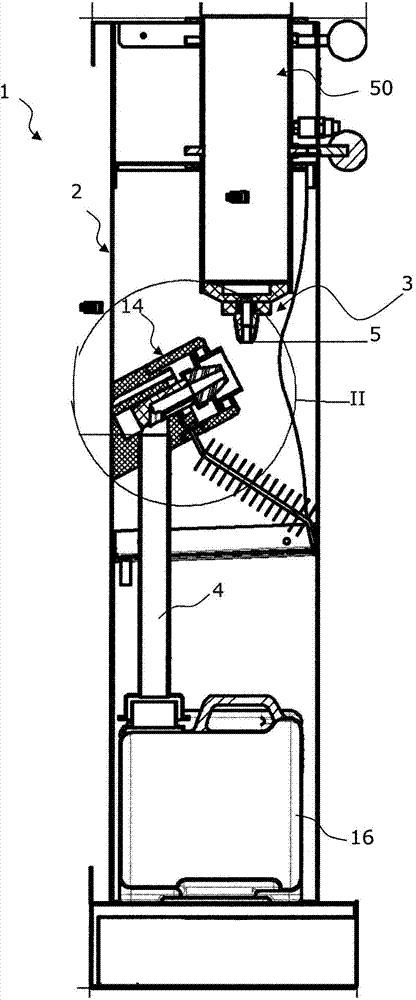

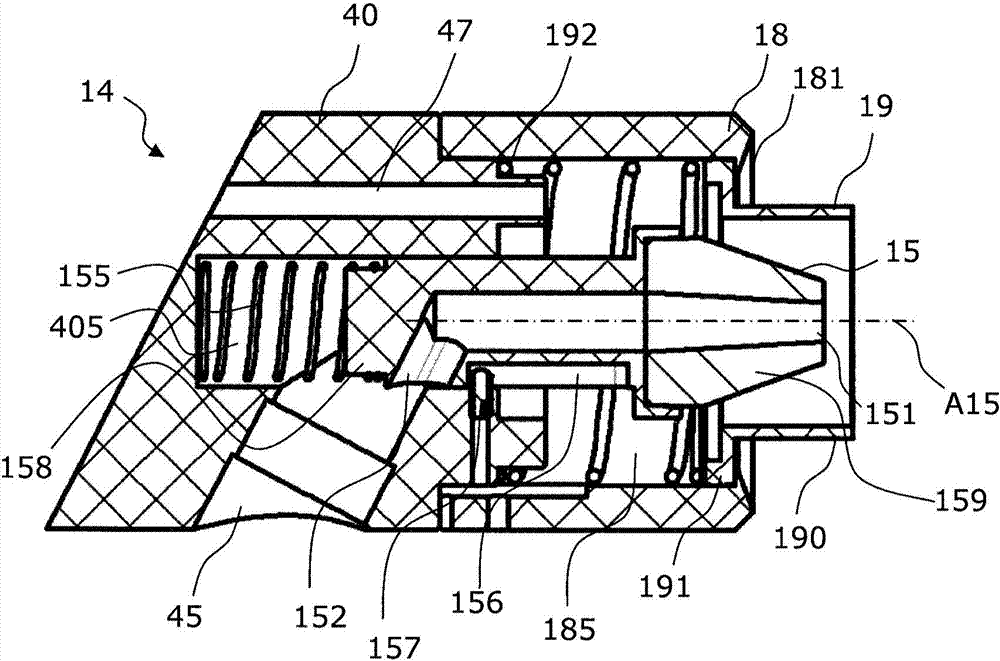

[0036] As indicated above, the cleaning device 1 of the present invention has a support structure 2 defining a cleaning volume, such as an enclosure, adapted to at least partially receive a spray gun 26 to be cleaned.

[0037] Specifically, the spray gun 26 is provided with a fluid inlet 27 for receiving the fluid to be sprayed and is provided with a fluid outlet 29, which is called "paint inlet" 27 and has an axis indicated by A27, and which is called "paint outlet". , the fluid outlet has an axis indicated at A29. An internal conduit connects the paint inlet 27 of the gun 26 to the paint outlet 29 .

[0038]Such guns are also provided with a gas inlet 31 which can be connected to a gas feed source such as a compressed air feed source. In particular, this air inlet 31 makes it possible to facilitate the flow of paint from the paint inlet 27 to the fluid outlet 29 and, when the trigger of the gun is actuated, to facilitate the ejection of paint from said gun. Said air inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com