Multi-strand double-turn stator coil forming device

A double-turn stator and coil forming technology is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc. It can solve the problems of large discreteness and difficult control of the quality of winding coils, and achieve the elimination of insulation damage, reliable quality, and effective outstanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

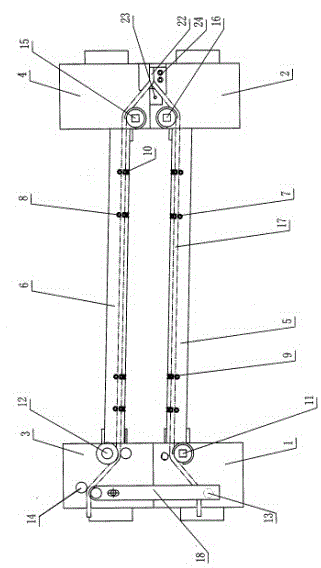

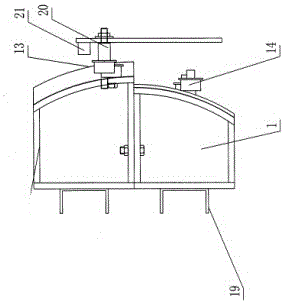

[0010] The present invention is described in detail below in conjunction with accompanying drawing:

[0011] A multi-strand double-turn stator coil forming device is mainly composed of a forming device fixing frame body and a movable bending handle 18, and the winding wire of the multi-strand double-turn stator coil 17 to be wound is placed on the forming device fixing frame body. The coil winding track winding arrangement, when the coil needs to be bent and at the corner, the sleeve 20 on the bending handle 18 is movably socketed on the corresponding column, and the pre-bent winding wire is clipped to the bending handle Between the bending column 21 on the 18 and the corresponding column, the bending handle 18 is rotated to the pre-bending direction, and the bending column 21 bends the winding line with the corresponding column as the supporting point. The whole molding device fixing frame body is fixed on the base beam 19, and the specific structure is: a left front support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com