HV-COB LED light source based on remote phosphor powder excitation

A technology of HV-COB LED and remote phosphor, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of small luminous flux of a single product, aging of LED chips, and lack of color rendering, so as to improve the light efficiency of products The effects of color rendering index, anti-aging, and improvement of light conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

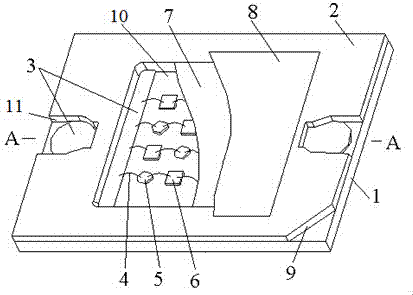

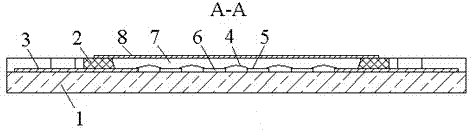

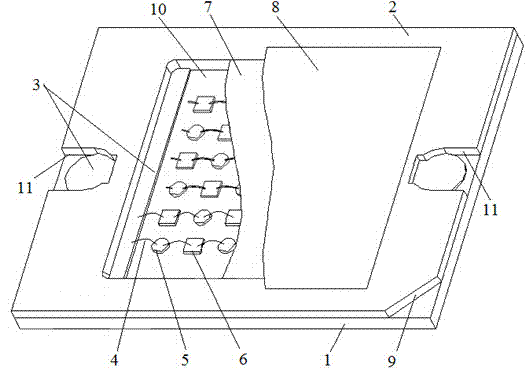

[0015] Such as figure 1 and figure 2 As shown, the first embodiment of the LED light source of the present invention includes a substrate 1, on which a square ring-shaped dam 2 made of COB dam glue is arranged, and a marking gap 9 is provided on the dam 2, and the middle part of the dam 2 It is a square bowl 10, and two gaps 11 are symmetrically arranged on the dam 2; two disconnected silver-plated pads 3 are arranged between the substrate 1 and the dam 2, and one end of the pad 3 extends into the bowl 10, the other end of the pad 3 is located outside the bowl 10, and a gap 11 exposes a part of the pad 3 outside the bowl 10; the substrate 1 in the bowl 10 is provided with four LED chip components in parallel, each The LED chip components are arranged along the connection direction of the two gaps 11, and all the LED chip components are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com