Automatic horn air leakage detection device and horn air leakage automatic detection method

An automatic detection device and horn technology, applied in the direction of liquid tightness measurement using liquid/vacuum, can solve the problems of wasting manpower, prone to misjudgment, easy to make people tired, etc., and achieve the effect of reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

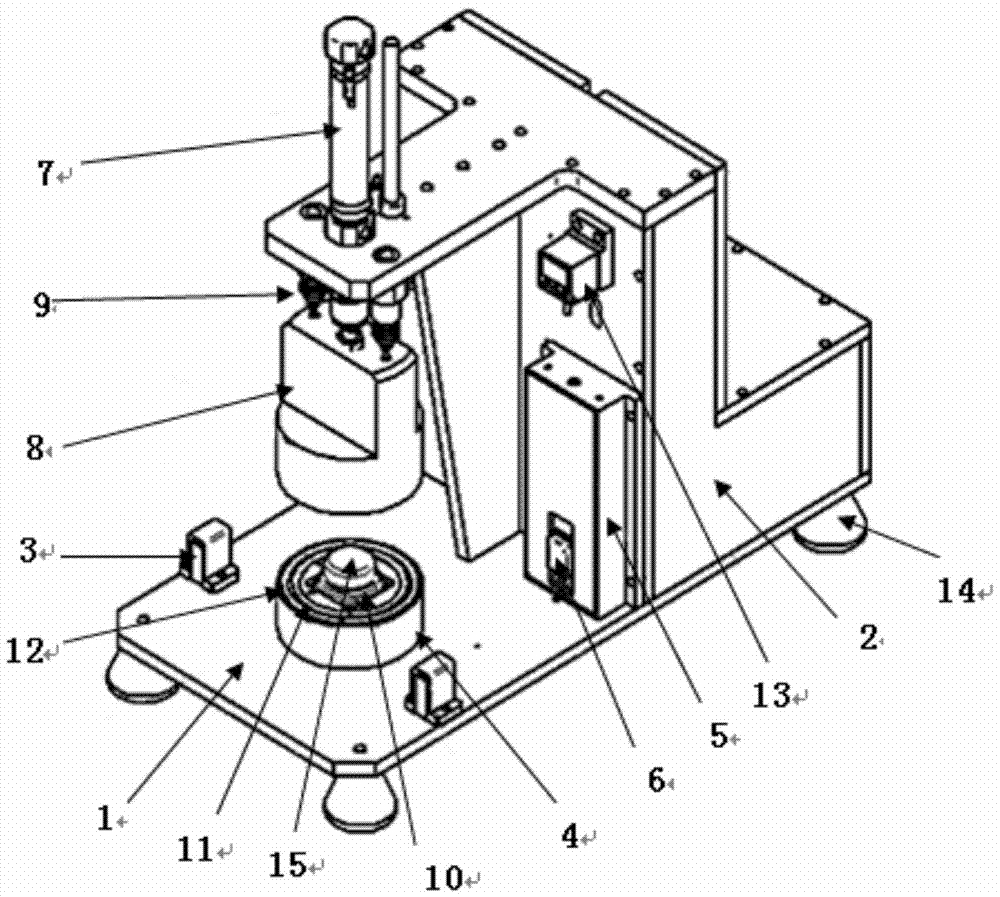

[0026] see figure 1 , the speaker air leakage automatic detection device of the present embodiment comprises a base plate 1, and the base plate 1 is fixed with an organic casing 2, a starting inductor 3, and a lower mold 4, and the casing 2 is provided with a gas source and a solenoid valve connected with the gas source, and the control The device is electrically connected with the solenoid valve; the outer wall of the casing 2 is provided with a water level box 5, and the water level box 5 is provided with a water level sensor 6; the top plate of the casing 2 is fixed with a lifting cylinder 7 electrically connected to the start sensor 3 , the top plate of the casing 2 is provided with an upper mold 8 connected to the lifting cylinder 7; the upper mold 8 has a first accommodating cavity with an open lower end, and the solenoid valve is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com