Engine

A technology of engine and connecting rod, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., which can solve the problems such as the unsmooth movement of the connecting rod and piston, and achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

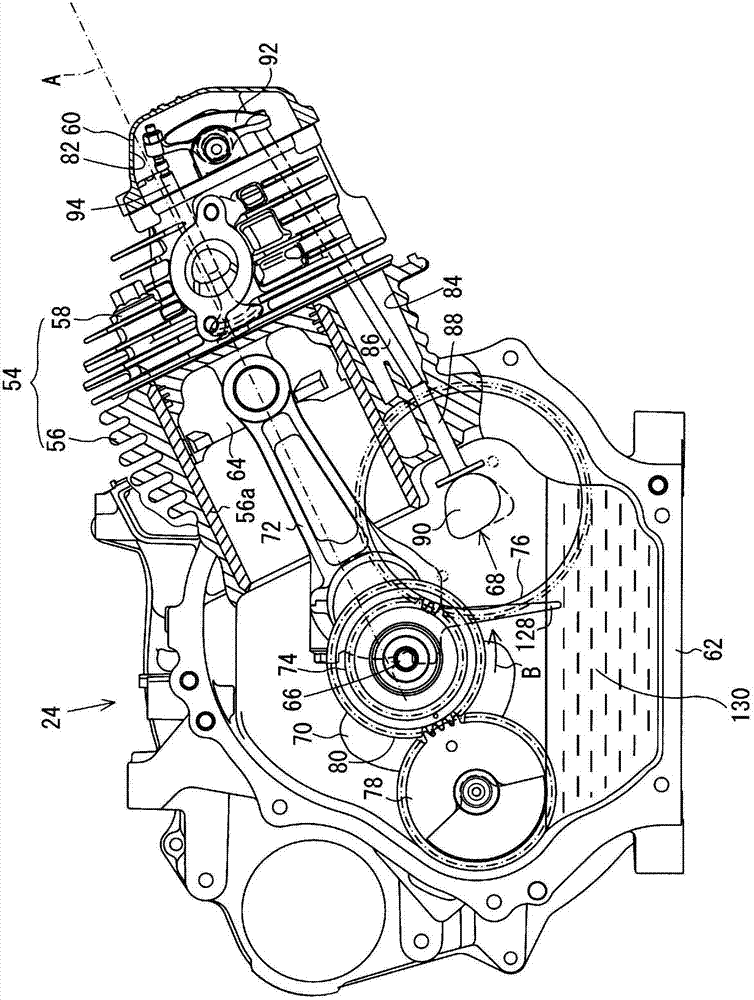

[0021] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

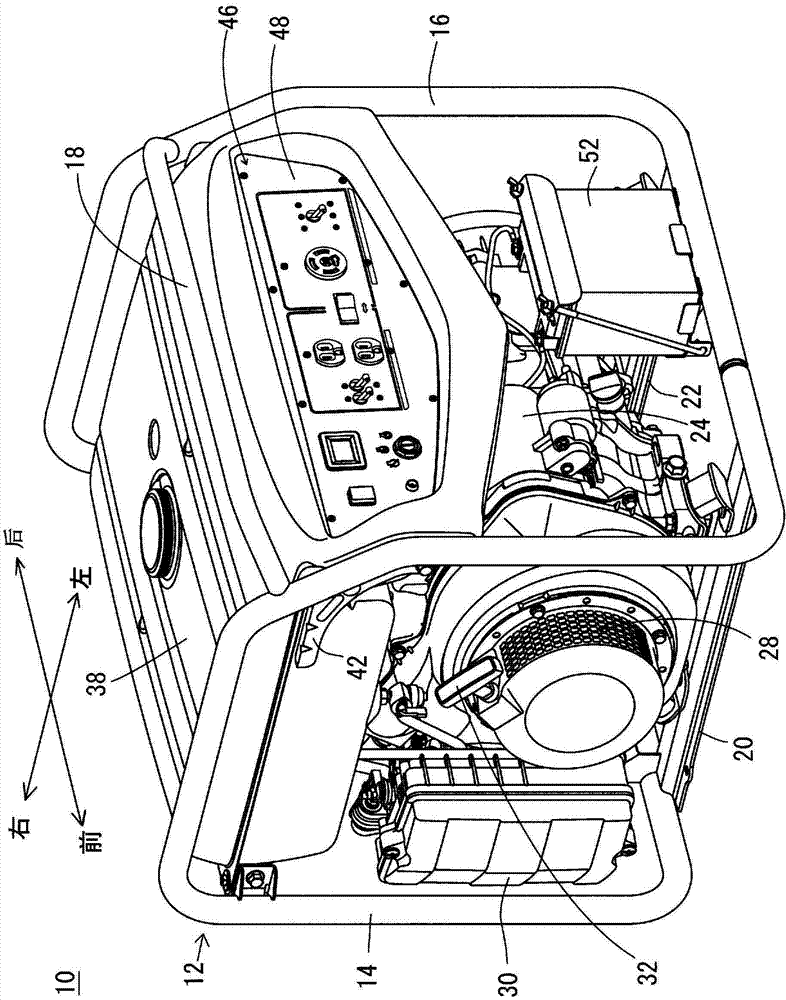

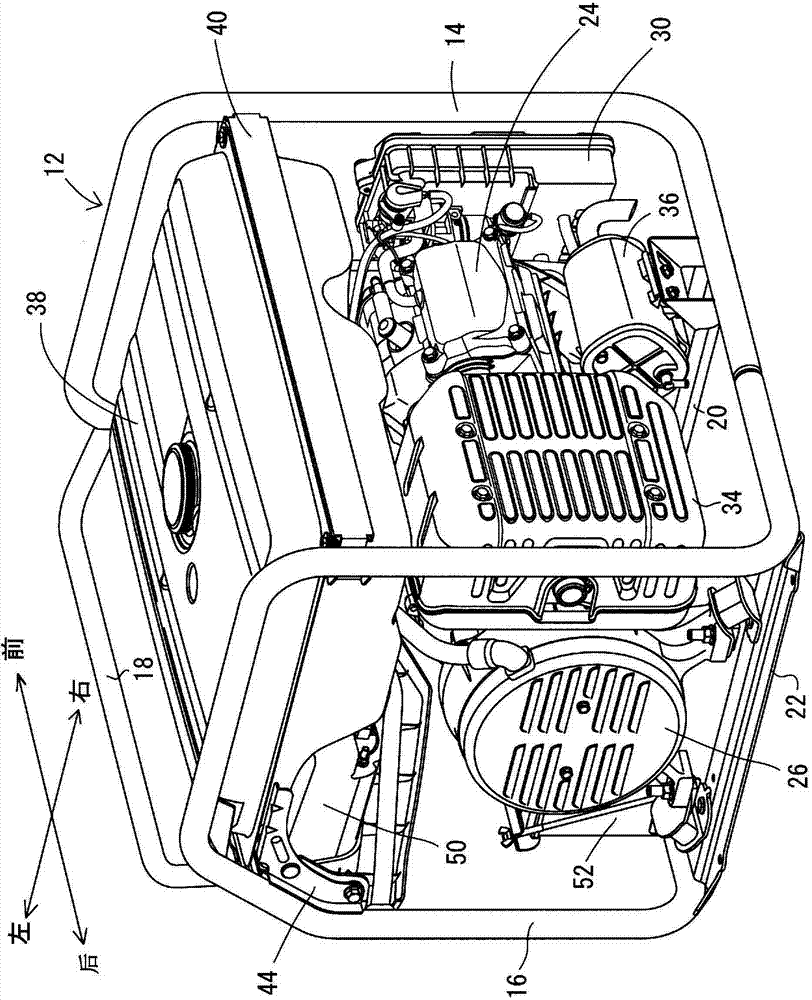

[0022] figure 1 with figure 2 An engine generator 10 including an engine 24 (described later) according to one embodiment of the present invention is shown. In this specification, for the convenience of description, in the engine generator 10, such as figure 1 with figure 2 As shown, define "front-back direction" and "left-right direction". Therefore, the side where the engine 24 is installed is "front", the side where the generator 26 (described later) is installed is "rear", and the side where the operation panel 48 (described later) is installed is "left".

[0023] The engine generator 10 is a portable generator and includes a generator frame (frame) 12 . The generator frame 12 includes a front frame 14 , a rear frame 16 , an upper frame 18 , and a pair of lower frames 20 , 22 . The front frame 14 is formed in a tubular shape and is generally in an inverted U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com