Steel floor buckling strip structures with edge being bent into arc shapes

A steel floor and bending technology, which is applied in the direction of building structure and construction, can solve the problems of easy deformation and unsightly edges of stainless steel floor buckles, etc., and achieve the effects of beautiful appearance, increased rigidity, and convenient packaging and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

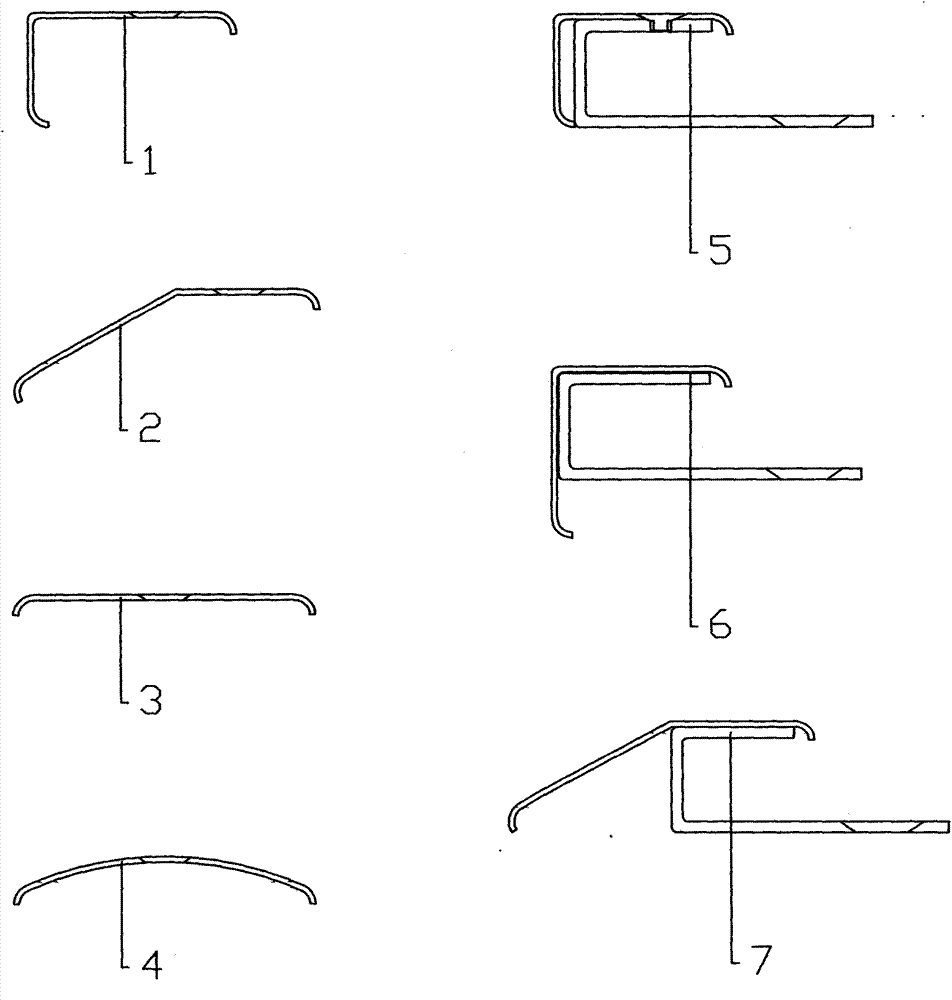

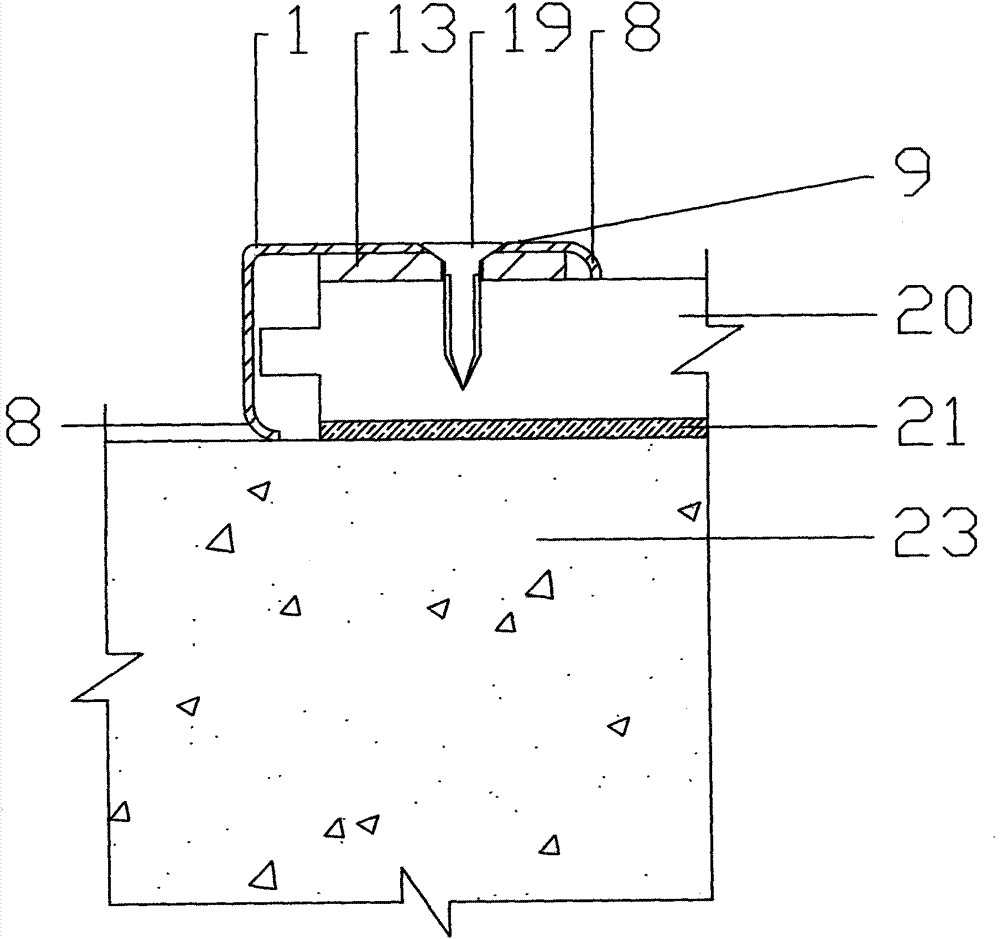

[0028] figure 1 Middle right angle 1 is the angle that the thin stainless steel plate is bent about 90 degrees, and the section of the edge bending arc 8 extends to both ends of the buckle.

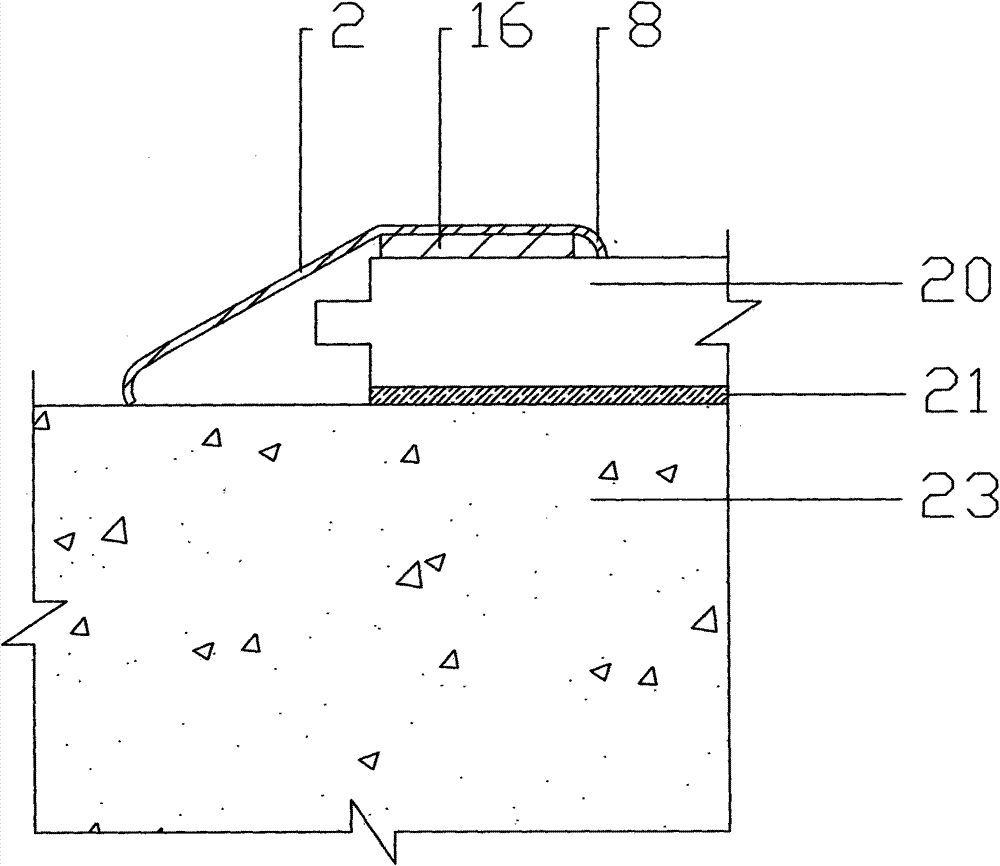

[0029] figure 1 The middle high and low buckle 2 is a buckle bar that bends the thin stainless steel plate at an obtuse angle, and the section of the edge bends the arc 8 to extend to both ends.

[0030] figure 1 The middle-level connecting buckle 3 is a buckle bar that extends the cross-section of the thin stainless steel plate edge to the curved arc 8 to both ends.

[0031] figure 1 The middle universal buckle 4 is a buckle bar that bends the thin stainless steel plate into an arc, and the section of the edge bends the arc 8 to extend to both ends.

[0032] attached figure 1 Middle C shape buckle 5 and stair buckle 6 are to assemble with right angle buckle 1 and grooved spacer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com