A flexible combined welding assembly line

A welding assembly line and flexible technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of lower welding production efficiency, high manufacturing cost, and narrow application range, so as to reduce equipment investment cost, The effect of reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

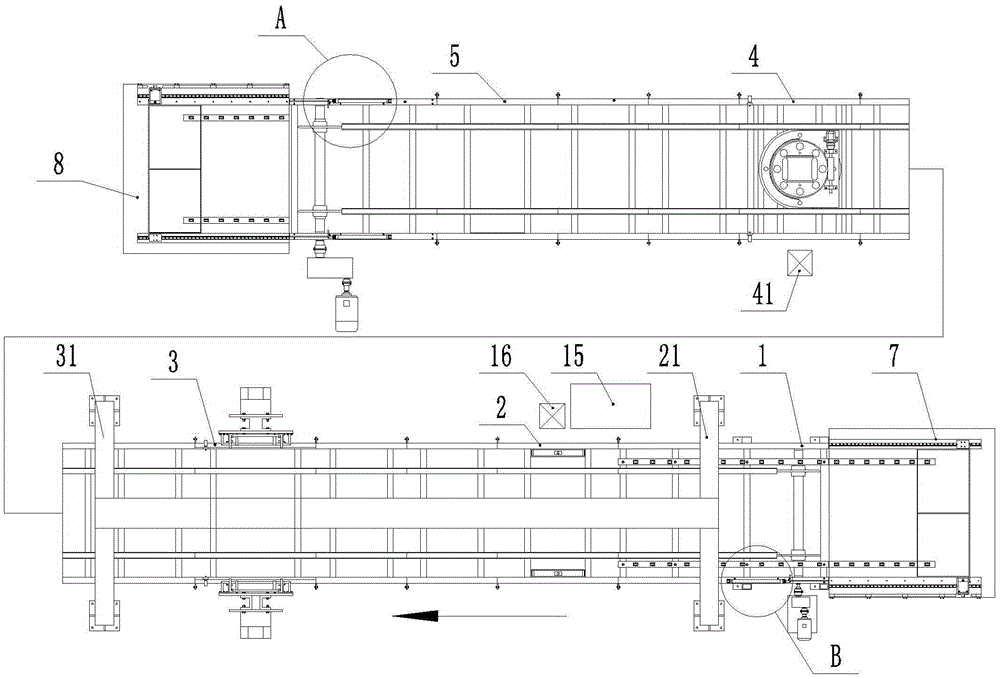

[0049] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, taking a flexible combined welding line with a non-displacement welding device, a flip welding device, and a rotary welding device in sequence as an example.

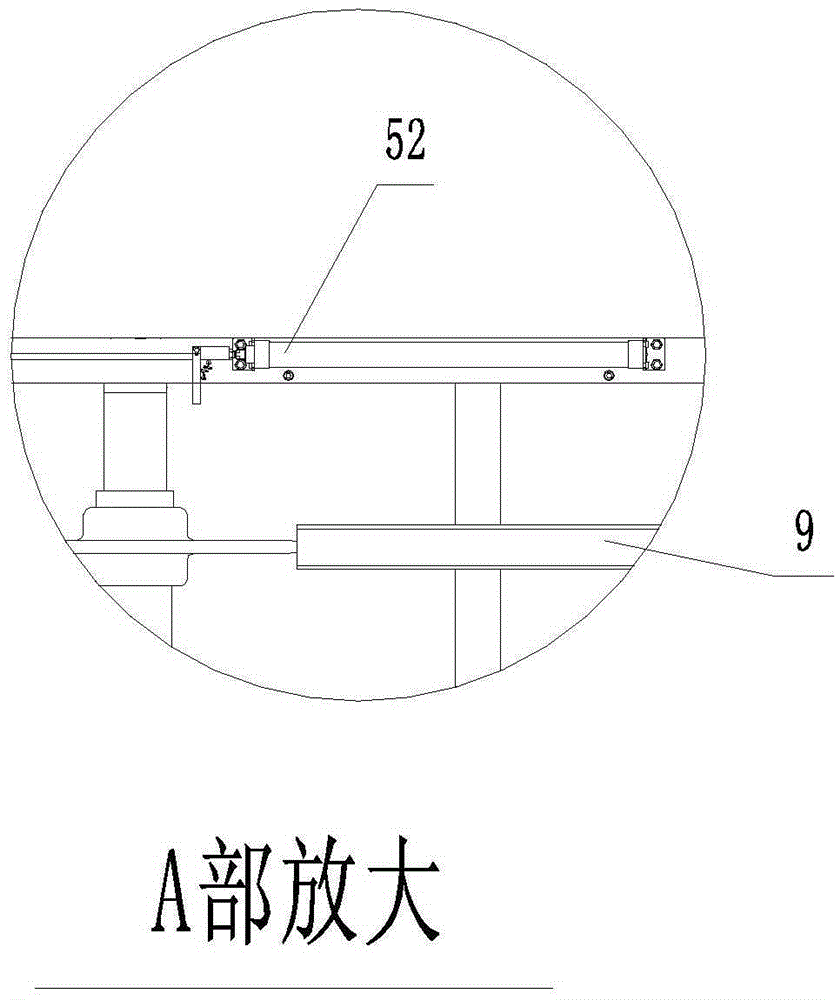

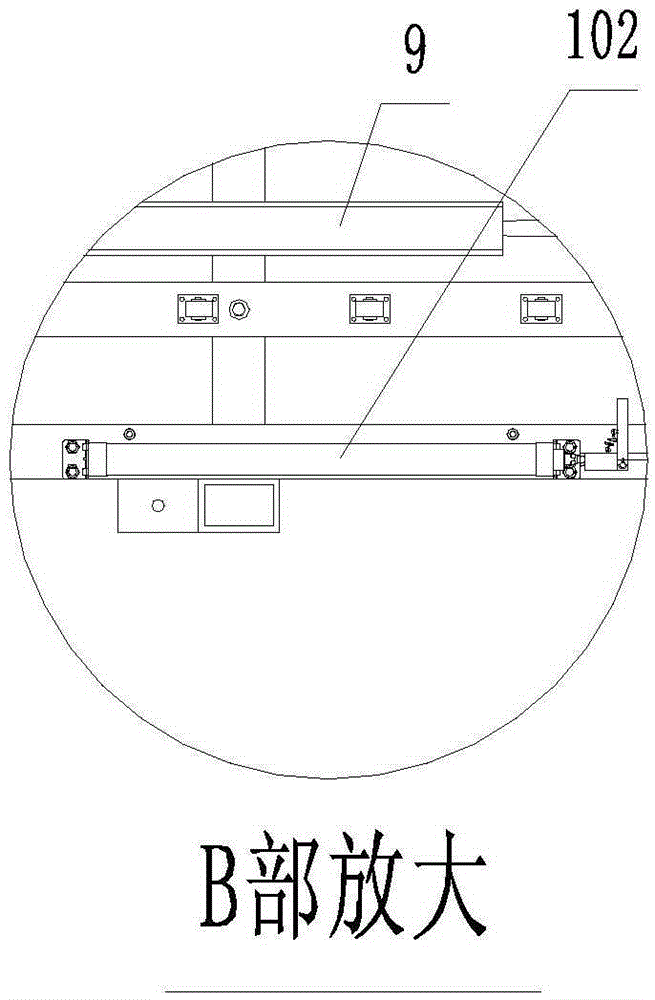

[0050] Such as Figure 1-3 As shown, a flexible combined welding line includes a conveying mechanism and five pallets 6 running in the conveying mechanism for clamping workpieces. The conveying mechanism includes a head-end module 1, three middle modules, and a tail-end module 5 that are detachably connected together, and two parallel forward conveying chains 9 that run through all the modules and two forward conveying chains 9 below. The return conveyor chain 10 arranged side by side. Positioning guide plates are respectively provided on both sides of the accompanying fixture 6 on the frame of the head end module 1 and the middle module. The conveying mechanism also includes a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com