Combined protective cover for linear cutting machine screw guide rail

A technology of wire cutting machine tools and protective covers, which is applied in the direction of maintenance and safety accessories, metal processing machinery parts, electric processing equipment, etc., and can solve the problems of large space occupation, large sliding friction resistance of floating sheet metal, and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

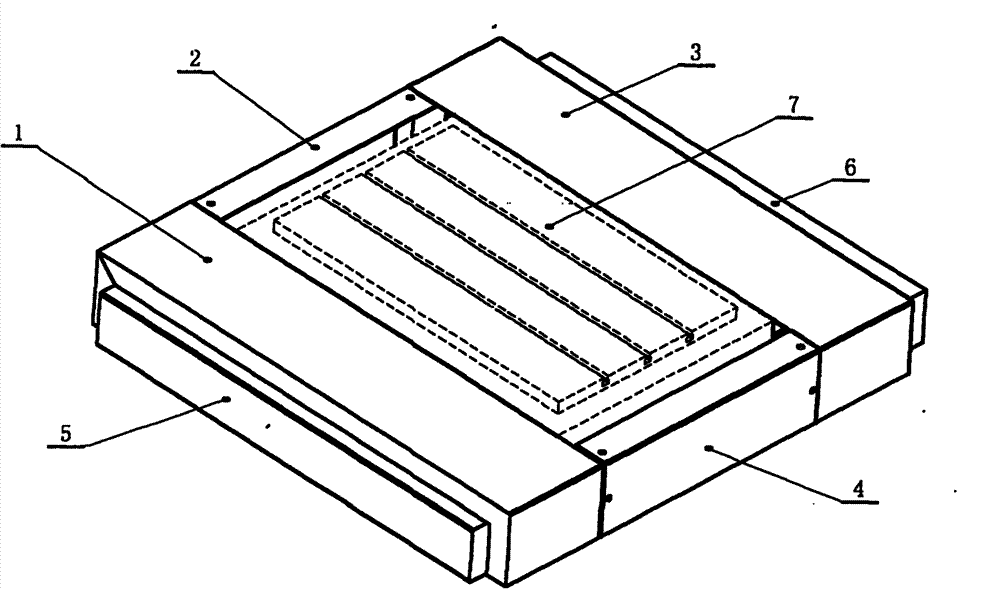

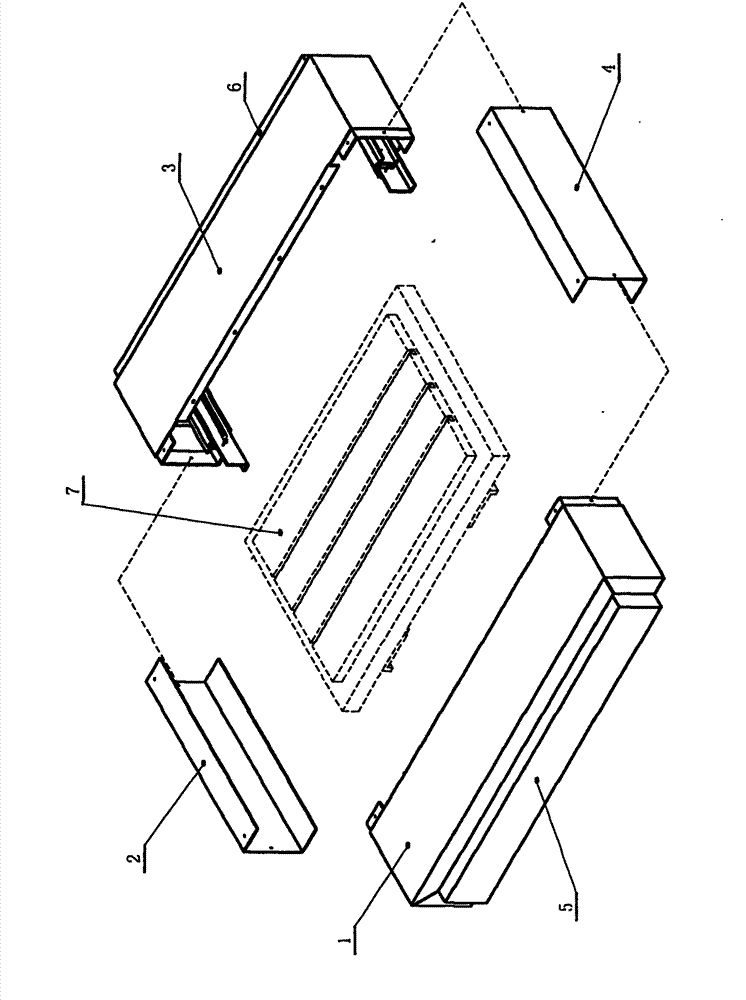

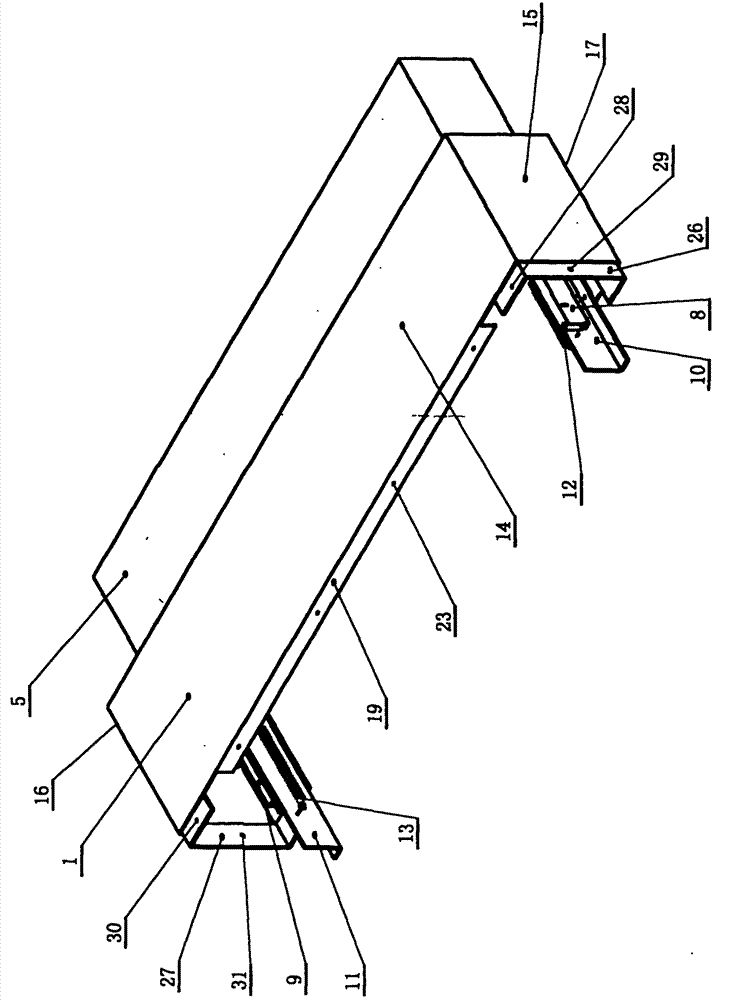

[0069]Refer to the accompanying drawings, the combined protective cover for the screw guide rail of the wire cutting machine tool is mainly composed of the front outer protective cover 1, the left connecting protective cover 2, the rear outer protective cover 3, the right connecting protective cover 4, and the front inner protective cover Cover 5, rear inner protective cover 6, left slide rail 8, right slide rail 9, left slide rail installation bent plate 10, right slide rail installation bend plate 11, left spring 12 and right spring 13, on the left slide rail 8 Two front and rear left moving rail holes 70 on the left moving rail 68 and two front and rear left sliding rail threaded holes 42 on the left sliding rail mounting plate 38 of the front inner layer protective cover 5 respectively wear a left moving rail Front bolt 80, left moving rail rear bolt 81, make left moving rail 68 be installed on the left sliding rail mounting plate 38, two left static rails on the left stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com