Preparation method of lactating sow feed

A technology for lactating sows and feed, which is applied in the field of preparation of lactating sows' feed, can solve the problems of low digestibility, poor palatability, and severe constipation of kelp, and achieve the content of easily digestible anti-nutritional factors, excellent palatability, The effect of amino acid balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

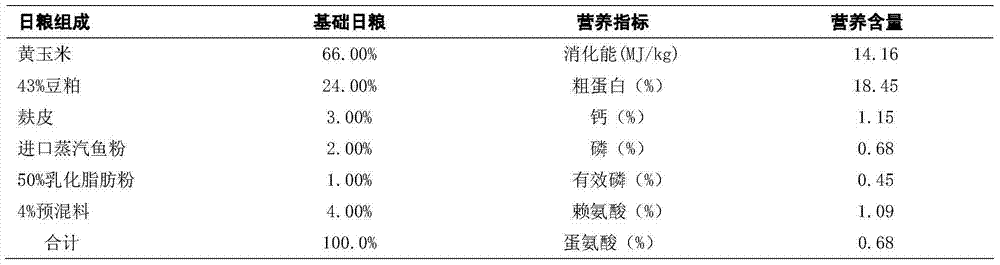

Method used

Image

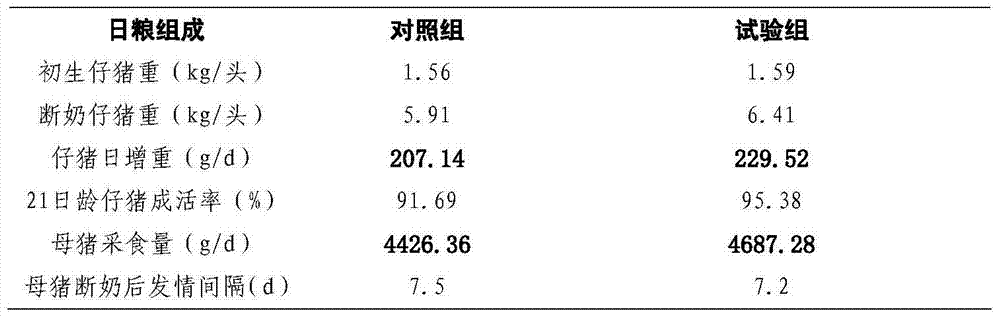

Examples

Embodiment 1

[0033] (1) After mixing 100kg of soybeans and 200kg of clean water, soak them at 35°C for 18 hours, refine them with a grinder, then heat them up to 95°C and cook them for 30 minutes, cool them down to 40°C, and separate them to obtain soybean pulp.

[0034] (2) Take 100kg of soybean pulp, 80kg of alfalfa grass powder, 30kg of corn flour, 15kg of brown sugar, 10kg of compound bacterial seed liquid and 0.005kg of compound enzyme, mix them, and perform solid-state fermentation and enzymolysis at 28°C for 48 hours, and then at 30°C The bean grass fermented material was obtained by drying under low temperature conditions.

[0035] (3) Take 100kg of bean grass fermented material, 100kg of corn, 30kg of broken rice, 40kg of soybean meal, 30kg of fish meal, 20kg of emulsified oil powder, 20kg of Jerusalem artichoke powder, 10kg of seaweed, 5kg of compound Chinese herbal medicine and 8kg of commercially available 4% premix and mix evenly Afterwards, feed for lactating sows is prepared...

Embodiment 2

[0037] (1) After mixing 100kg of soybeans and 300kg of clean water, soak them at 45°C for 18 (30) hours, after refining them with a grinder, heat them up to 95-100°C and cook for 30-60 minutes, then cool to 40-50°C °C, separate and obtain soybean pulp residue.

[0038] (2) Take 100kg of soybean pulp, 120kg of alfalfa powder, 40kg of corn flour, 20kg of brown sugar, 15kg of compound strain liquid and 0.05kg of compound enzyme, mix them in solid-state fermentation and enzymolysis at 32°C for 72 hours, and then at 40°C The bean grass fermented material was obtained by drying under low temperature conditions.

[0039] (3) Take 100kg of bean grass fermented material, 150kg of corn, 60kg of broken rice, 80kg of soybean meal, 60kg of fish meal, 40kg of emulsified oil powder, 40kg of Jerusalem artichoke powder, 20kg of seaweed, 8kg of compound Chinese herbal medicine and 15kg of commercially available 4% premix and mix evenly Afterwards, feed for lactating sows is prepared.

Embodiment 3

[0041] (1) After mixing 100kg of soybeans and 250kg of clean water, soak them at 40°C for 25 hours, refine them with a grinder, then heat them up to 98°C and cook them for 45 minutes, cool them to 45°C, and separate them to obtain soybean pulp residue.

[0042] (2) Take 100kg of soybean residue, 100kg of alfalfa powder, 35kg of corn flour, 18kg of brown sugar, 12kg of compound bacterial seed liquid and 0.02kg of compound enzyme, mix them in solid-state fermentation and enzymolysis at 30°C for 50 hours, and then in 35°C The bean grass fermented material was obtained by drying under low temperature conditions.

[0043] (3) Take 100kg of bean grass fermented material, 120kg of corn, 50kg of broken rice, 60kg of soybean meal, 45kg of fish meal, 30kg of emulsified oil powder, 30kg of Jerusalem artichoke powder, 15kg of seaweed, 6kg of compound Chinese herbal medicine and 10kg of commercially available 4% premix and mix evenly Afterwards, feed for lactating sows is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com