Extended operating cycle for pressurized water reactor

A technology of pressurized water reactors and nuclear reactors, applied in the direction of reactors, nuclear reactors, overall reactors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Detailed description of preferred embodiments

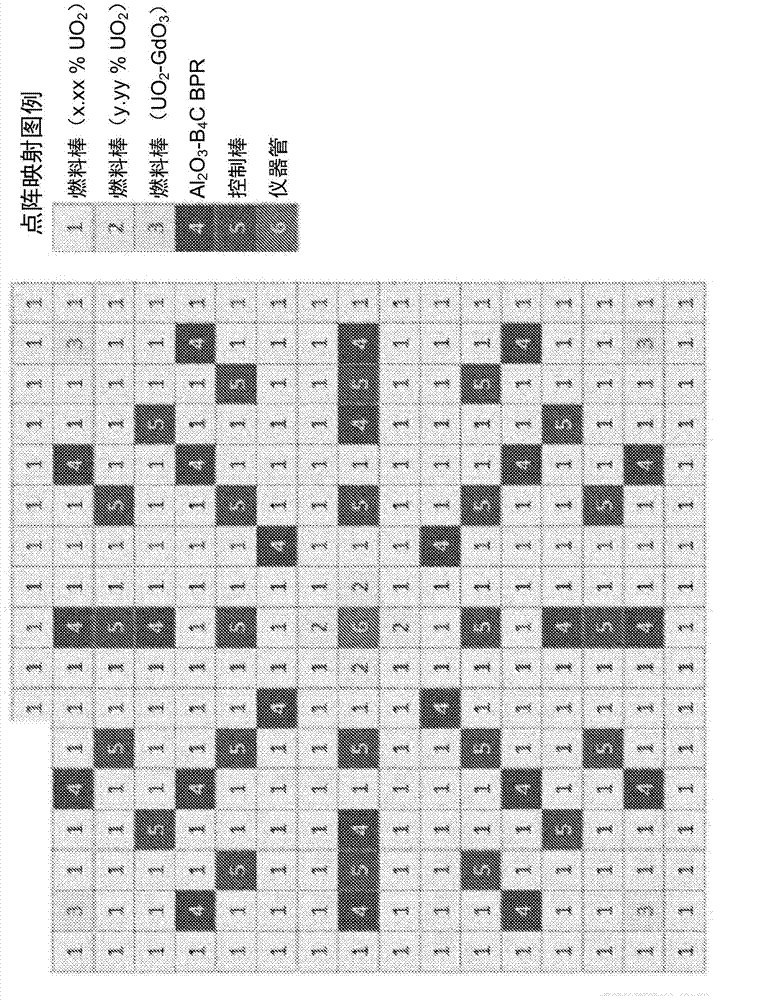

[0022] This paper discloses an improved fuel cycle management technology for pressurized water reactors (PWR), which can extend the operation cycle without using soluble poisons such as soluble boron for reaction rate control, and optionally without fuel Component rearrangement.

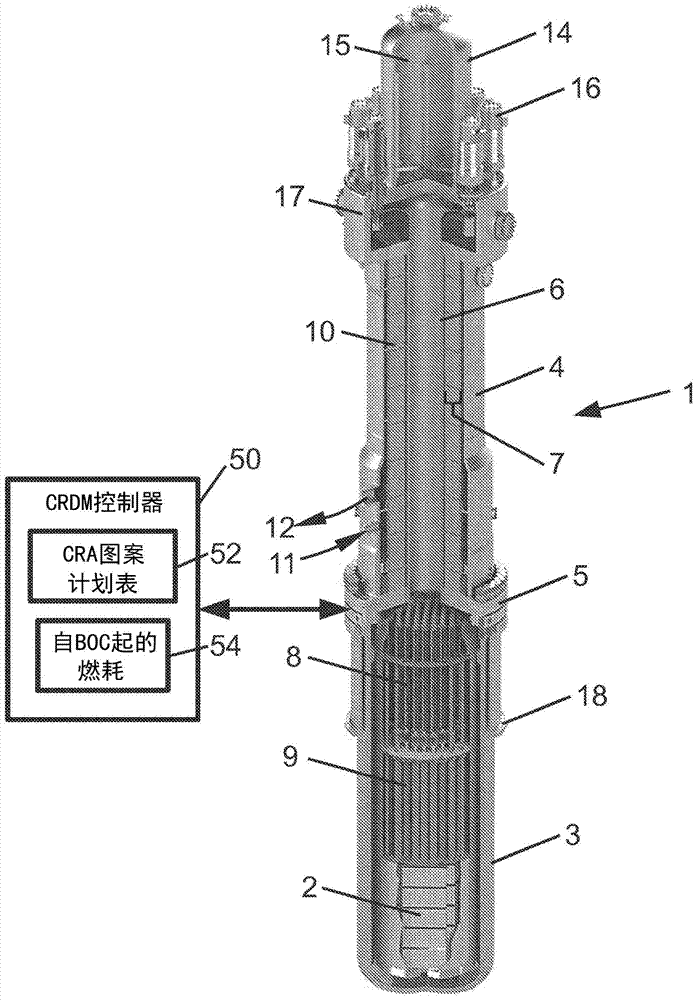

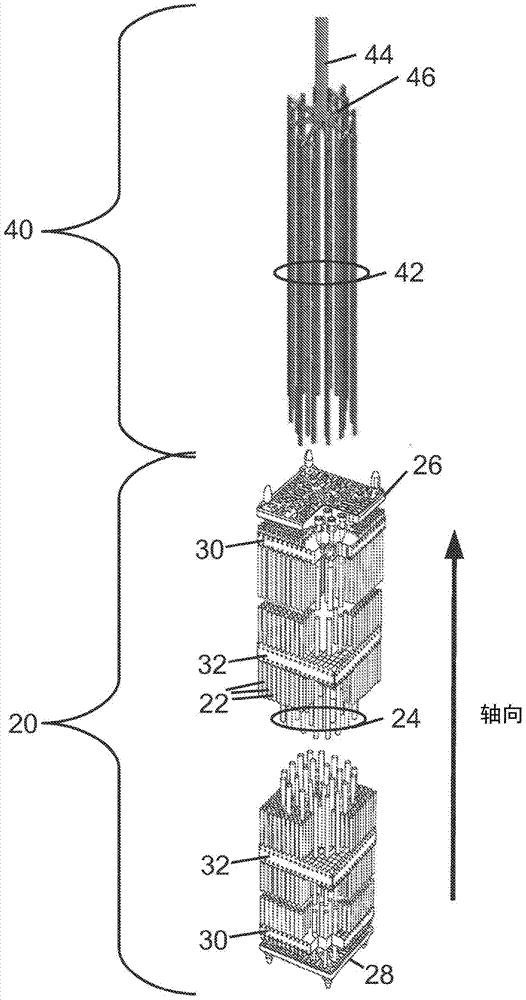

[0023] reference figure 1 , Shows an illustrative small modular reactor (SMR) 1, with which the reaction rate control technology disclosed herein can be suitably adopted. Illustrative SMR 1 is a type of pressurized water reactor (PWR). The illustrative PWR 1 includes a nuclear reactor core 2 disposed in a pressure vessel, which in the illustrative embodiment includes a lower vessel portion 3 and an upper vessel portion 4 connected by a middle flange 5. The reactor core 2 is arranged in the lower vessel part 3 and includes fissionable materials immersed in the main cooling water (such as: 235 U). A cylindrical central riser 6 is coaxially arranged i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com