Automobile sensor protection circuit

A technology for automotive sensors and protection circuits, applied in emergency protection circuit devices, overvoltage-responsive protection, electrical components, etc. Overvoltage protection circuit and other issues to achieve the effect of improving integration and stability, reducing production costs, and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

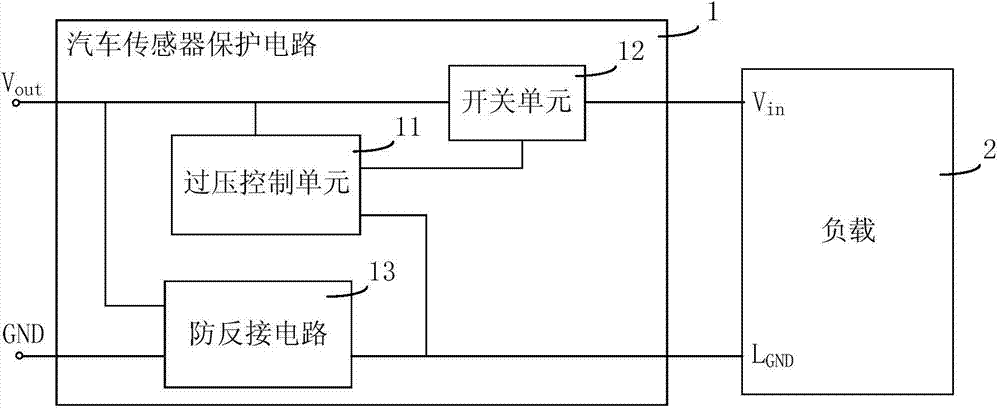

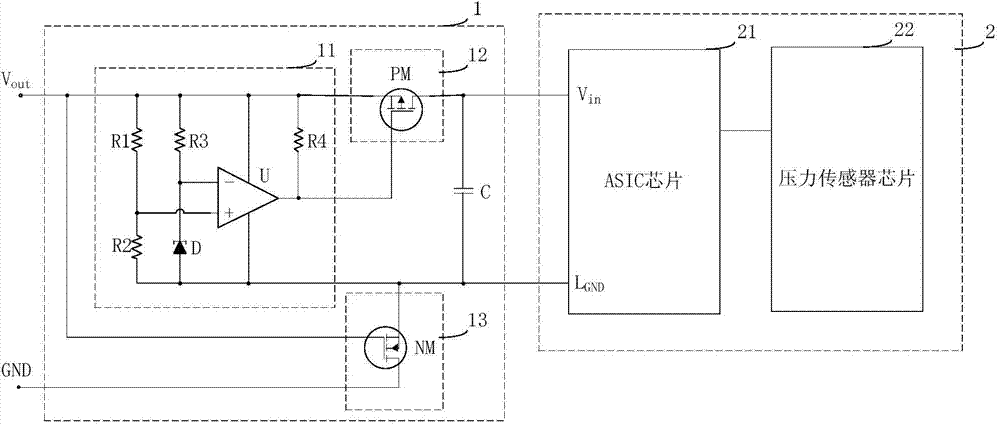

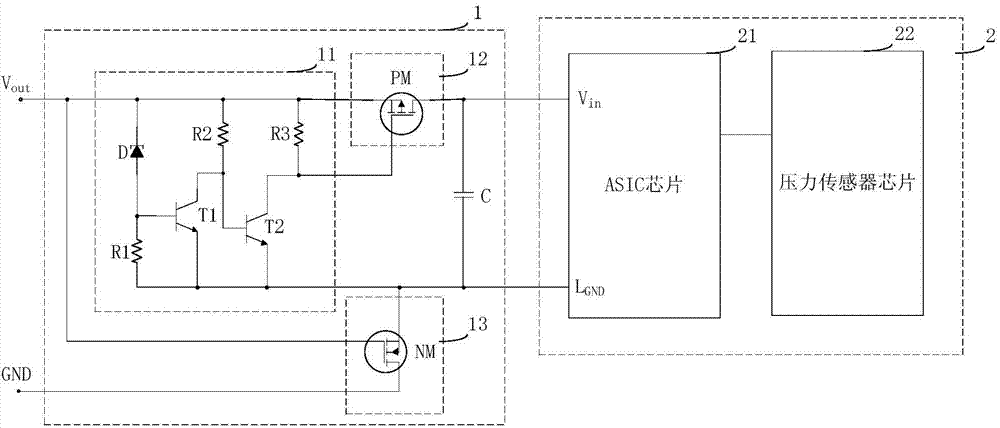

[0044] Such as figure 1 As shown, the automotive sensor protection circuit 1 of the present invention includes an overvoltage control unit 11, a switch unit 12 and an anti-reverse connection unit 13; wherein, the overvoltage control unit 11 is connected to the power supply terminal V out , Load ground terminal L GND , and between the control terminals of the switch unit 12; the input terminal of the switch unit 12 is connected to the power supply terminal V out , the output terminal of the switch unit 12 is connected to the load receiving terminal V in ; The overvoltage control unit 11 according to the power supply terminal V out The voltage change controls the opening and closing of the switch unit 12; the anti-reverse connection unit 13 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com