A pouring trolley control system for railway track bed solidification equipment

A technology of pouring trolleys and curing equipment, applied in the direction of two-dimensional position/channel control, etc., can solve problems such as unfavorable construction, inability to automatically locate, inconvenient adjustment of pouring volume and flow rate, etc., to reduce labor intensity, ensure standardization and Stability, work efficiency and quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

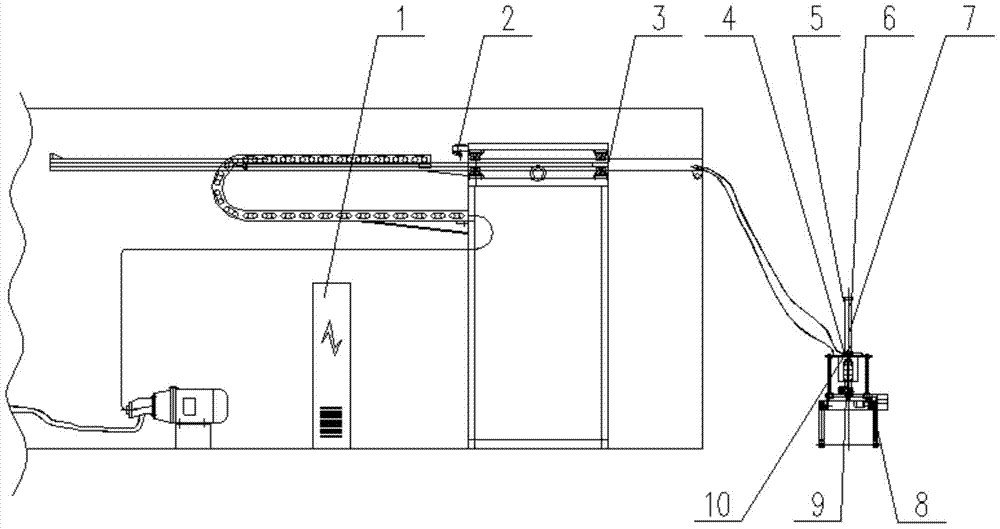

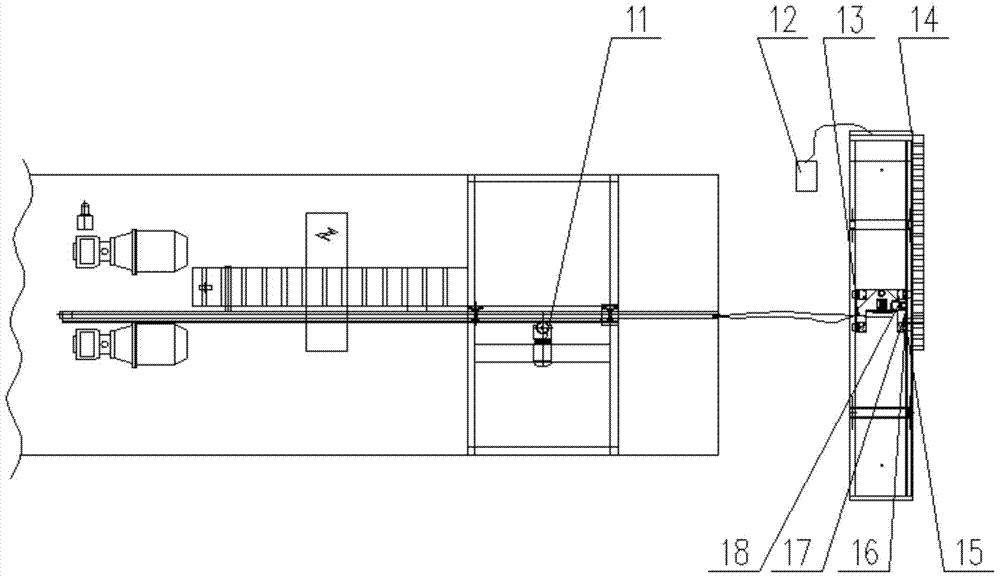

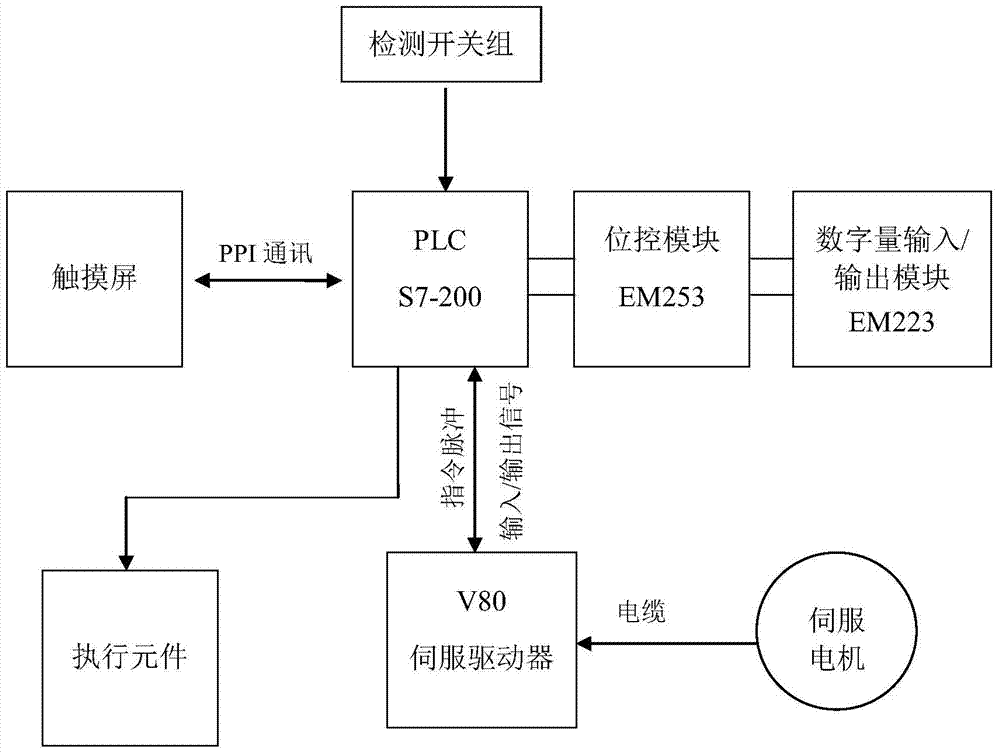

[0020] Such as Figure 1 to Figure 5 As shown, the present invention includes a control module, a position control module, a detection switch group, a touch screen, a digital input / output module, an actuator, a servo driver and a servo motor 18, and the detection switch group is connected to the control module, and the control module is respectively connected to the touch screen, The actuator, the position control module are connected to the servo driver, the position control module is connected to the digital input / output module, and the servo driver is connected to the servo motor 18; the detection switch group includes the boom out limit switch 2, the boom back limit switch Position switch 3, lifting cylinder upper switch 6, lifting cylinder lower switch 10, reference point proximity switch 17, negative limit proximity switch 13 and positive limit proximity switch 15, bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com