An anti-leakage composite barrier

An anti-leakage and barrier technology, applied in the direction of protection devices, buildings, infrastructure engineering, etc., can solve the problems of leakage and joints that cannot be treated well, achieve good anti-seepage effect, simple construction, and solve the problem of winding seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

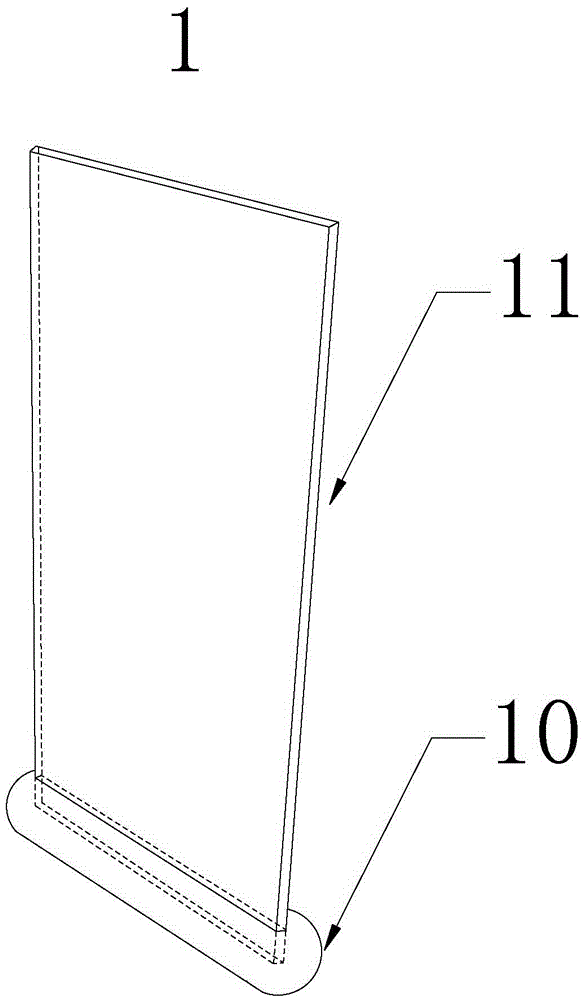

[0035] combine Figure 1~3 Shown, anti-leakage composite barrier 1 of the present invention comprises:

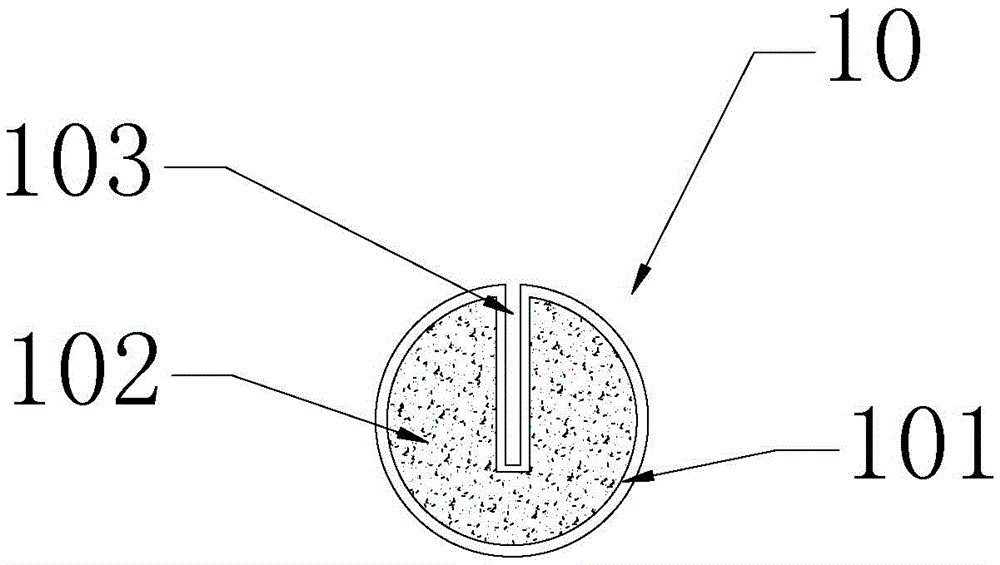

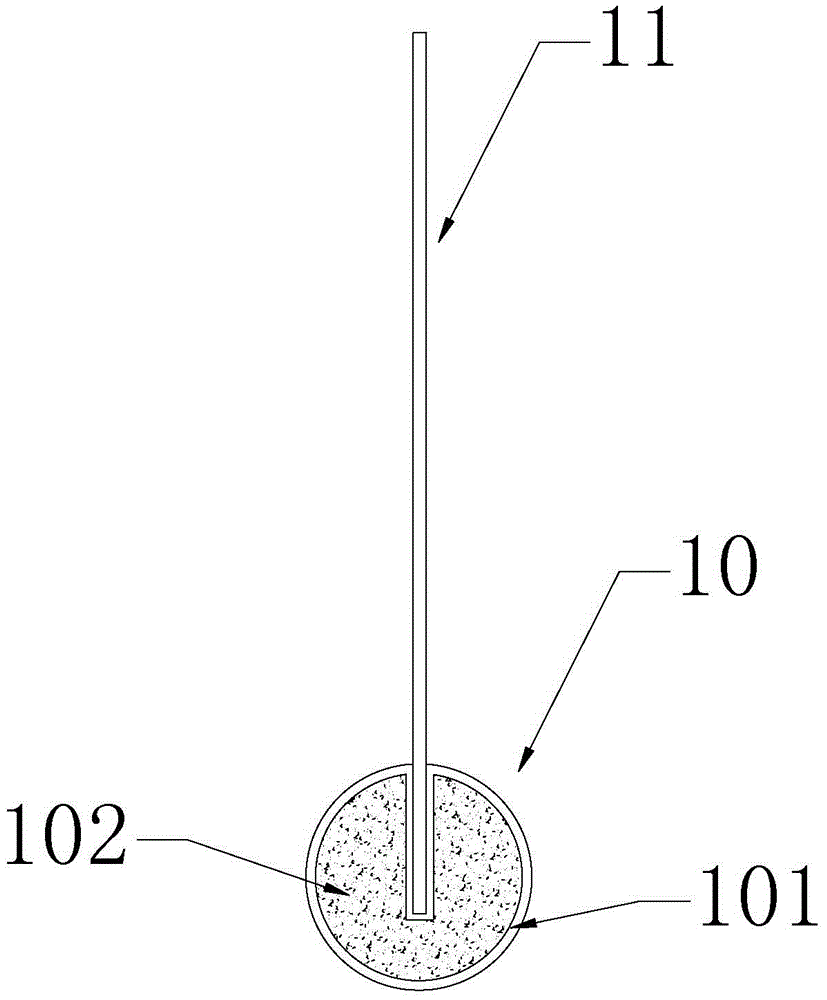

[0036] Anti-winding part 10, such as figure 1 As shown, including a water-soluble polymer film 101 and an expansive clay 102 encapsulated in the water-soluble polymer film, grooves 103 are formed on the surface of the anti-infiltration part 10;

[0037] anti-seepage layer 11, such as figure 2 , 3 As shown, its bottom is embedded in the groove 103 of the anti-winding part 10 .

[0038] Specifically, the anti-seepage layer 11 can be a rectangular HDPE geomembrane, and the anti-seepage portion 10 is cylindrical, and its cross-section can be circular, square, elliptical or irr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com