Shielding type plastic film and composite belt prepared therefrom

A plastic film and shielding technology, which is applied in the fields of magnetic field/electric field shielding, synthetic resin layered products, electrical components, etc., can solve the problem of poor adhesion between plastic film and sheath or metal, inconsistent functions, and low electrical conductivity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A kind of composite tape, the structure is to be provided with shielding type plastic film layer on one side of metal layer, wherein metal layer is aluminum foil, the preparation method of composite tape comprises the following steps:

[0068] 1) Wet ball milling of metal oxides, Fe 2 o 3 and NiO according to the mass ratio of 1.08:2.35, the total mass of metal oxides and anhydrous ethanol according to the mass ratio of 2:1, the total mass of grinding balls and metal oxides according to the mass ratio of 13:1.1, and then the weighed grinding balls Put it into the grinding jar, then add Fe 2 o 3 , NiO and absolute ethanol, and finally ball milled at a speed of 200r / min for 10h.

[0069] 2) Sieving the metal oxide, drying the metal oxide obtained in step 1) in an oven at 110° C. for 4 hours, and then sieving through a 250-mesh gauze.

[0070] 3) Surface treatment of hollow glass microspheres, weighing the surface treatment liquid and hollow glass microspheres accordin...

Embodiment 2

[0082] A kind of composite tape, the structure is to be provided with shielding type plastic film layer on one side of metal layer, wherein metal layer is aluminum foil, the preparation method of composite tape comprises the following steps:

[0083] 1) Wet ball milling of metal oxides, Fe 2 o 3 and NiO according to the mass ratio of 1.08:2.35, the total mass of metal oxides and anhydrous ethanol according to the mass ratio of 2:1, the total mass of grinding balls and metal oxides according to the mass ratio of 13:1.1, and then the weighed grinding balls Put it into the grinding jar, then add Fe 2 o 3 , NiO and absolute ethanol, and finally ball milled at a speed of 200r / min for 10h.

[0084] 2) Sieving the metal oxide, drying the metal oxide obtained in step 1) in an oven at 110° C. for 4 hours, and then sieving through a 250-mesh gauze.

[0085] 3) Surface treatment of hollow glass microspheres, weighing the surface treatment liquid and hollow glass microspheres accordin...

Embodiment 3

[0097] A kind of composite tape, the structure is that a shielding type plastic film layer is arranged on one side of the metal layer, wherein the metal layer is aluminum foil, and the preparation method of the composite tape comprises the following steps:

[0098] 1) Wet ball milling of metal oxides, Fe 2 o 3 and NiO according to the mass ratio of 1.08:2.35, the total mass of metal oxides and anhydrous ethanol according to the mass ratio of 2:1, the total mass of grinding balls and metal oxides according to the mass ratio of 13:1.1, and then the weighed grinding balls Put it into the grinding jar, then add Fe 2 o 3 , NiO and absolute ethanol, and finally ball milled at a speed of 200r / min for 10h.

[0099] 2) Sieving the metal oxide, drying the metal oxide obtained in step 1) in an oven at 110° C. for 4 hours, and then sieving through a 250-mesh gauze.

[0100] 3) Surface treatment of hollow glass microspheres, weighing the surface treatment liquid and hollow glass microsph...

PUM

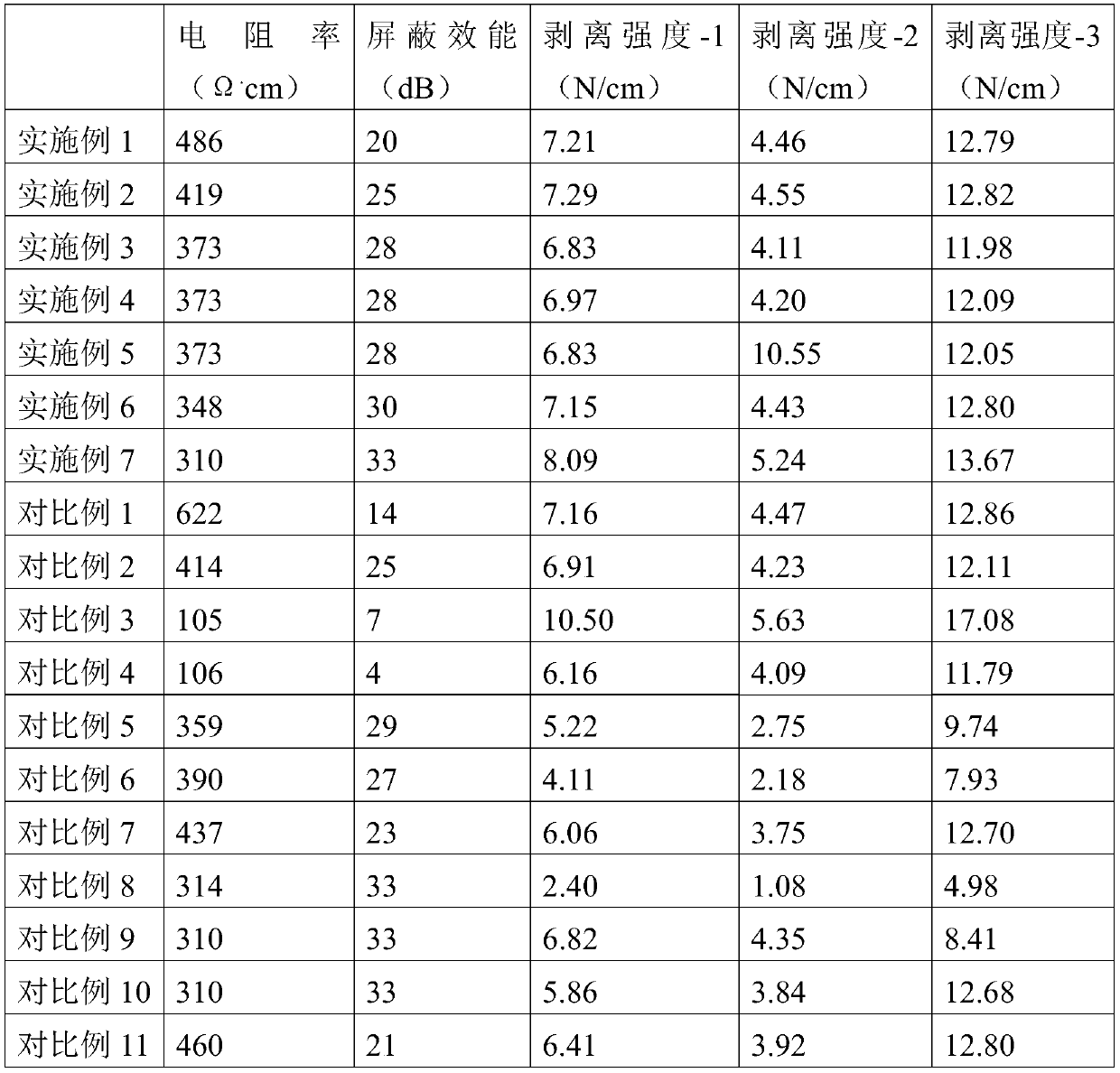

| Property | Measurement | Unit |

|---|---|---|

| Volume resistance | aaaaa | aaaaa |

| Shielding effectiveness | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com