Underground continuous wall anti-flow-around rubber pipe and H-shaped steel combined connecting joint and construction method

A technology of underground diaphragm wall and combined connection, which is applied to sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of low cost, solving the problem of circumvention, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

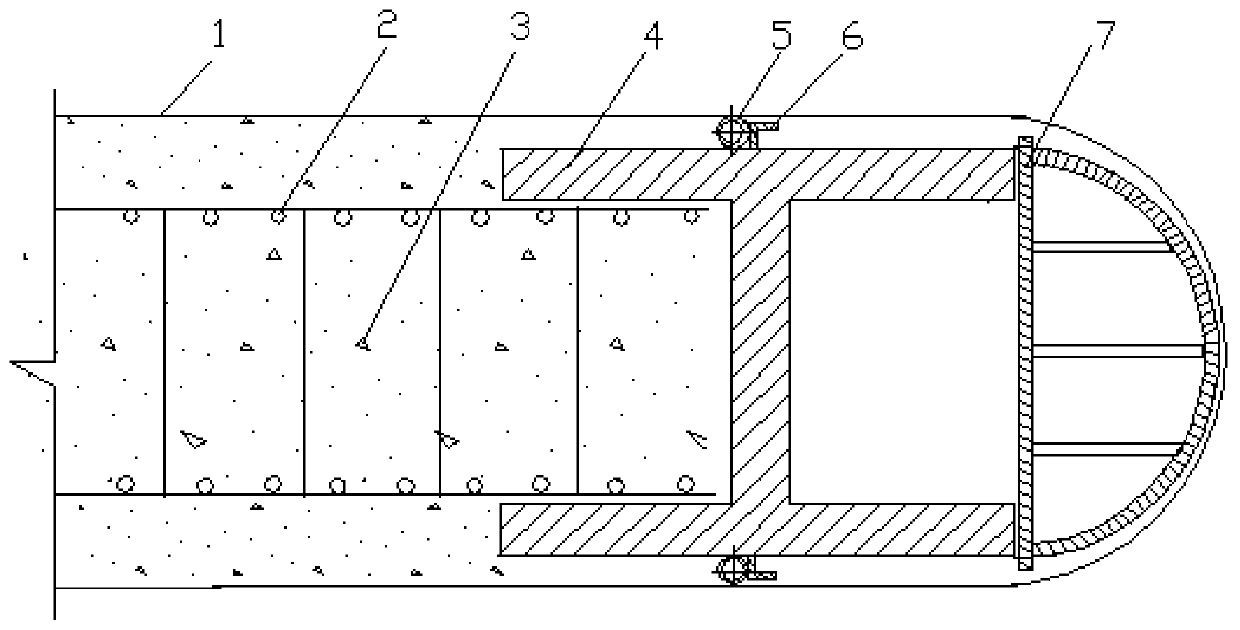

[0025] Such as figure 1 As shown, the connection joint of underground diaphragm wall anti-circumvention rubber hose and H-shaped steel combination of the present invention mainly includes groove wall 1, underground diaphragm wall reinforcement cage 2 of unit groove section, concrete A3, H-shaped steel 4, soft rubber hose 5, angle steel 6, half Round lock tube 7. In this embodiment, the depth of the underground diaphragm wall is 21m, the width of the cell wall of the unit groove section is 800mm, and the length is 6000mm. is 6800mm; the length of the reinforced cage of the underground diaphragm wall of the unit groove section is 5650mm, the width is 640mm, and the thickness of the concrete protective layer is 80mm.

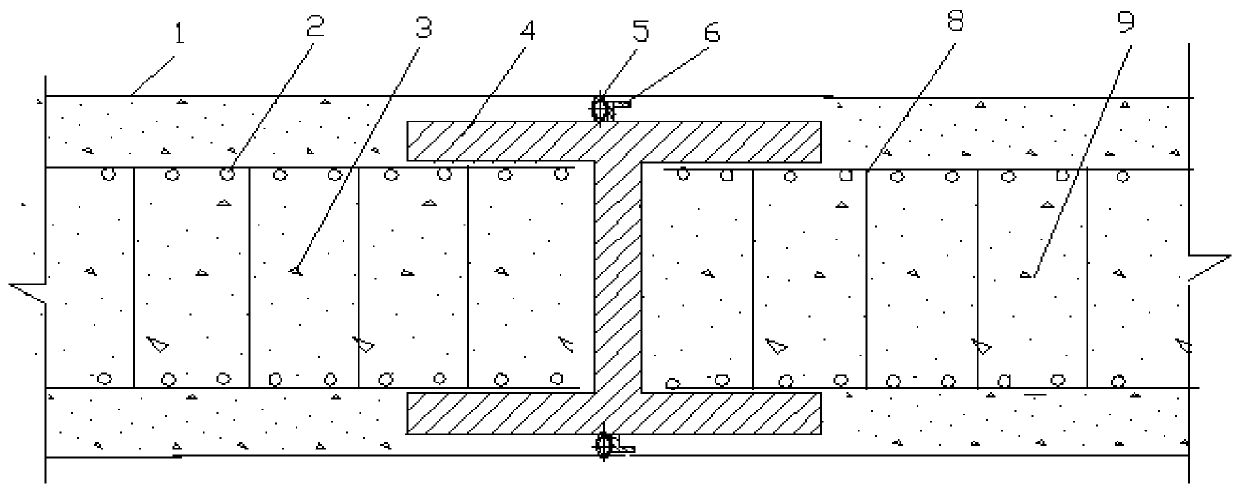

[0026] Such as figure 2 As shown, a 700×300 H-shaped steel is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com