Anti-explosion waterproof breathable valve

A waterproof breathable valve, waterproof breathable membrane technology, applied in the direction of safety valve, balance valve, valve device, etc., can solve the problems of high product maintenance cost and replacement difficulty, users can not detect in time, membrane leakage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

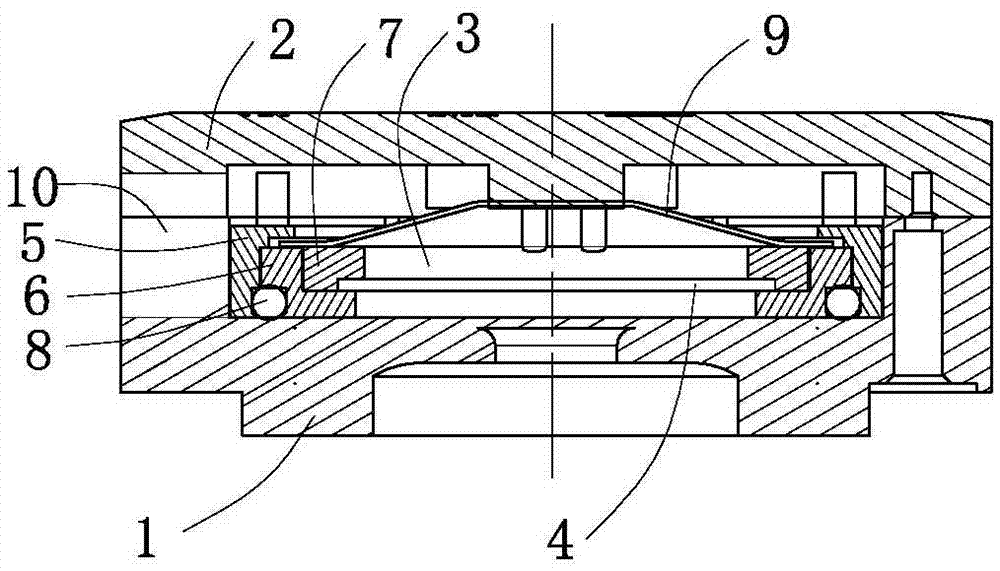

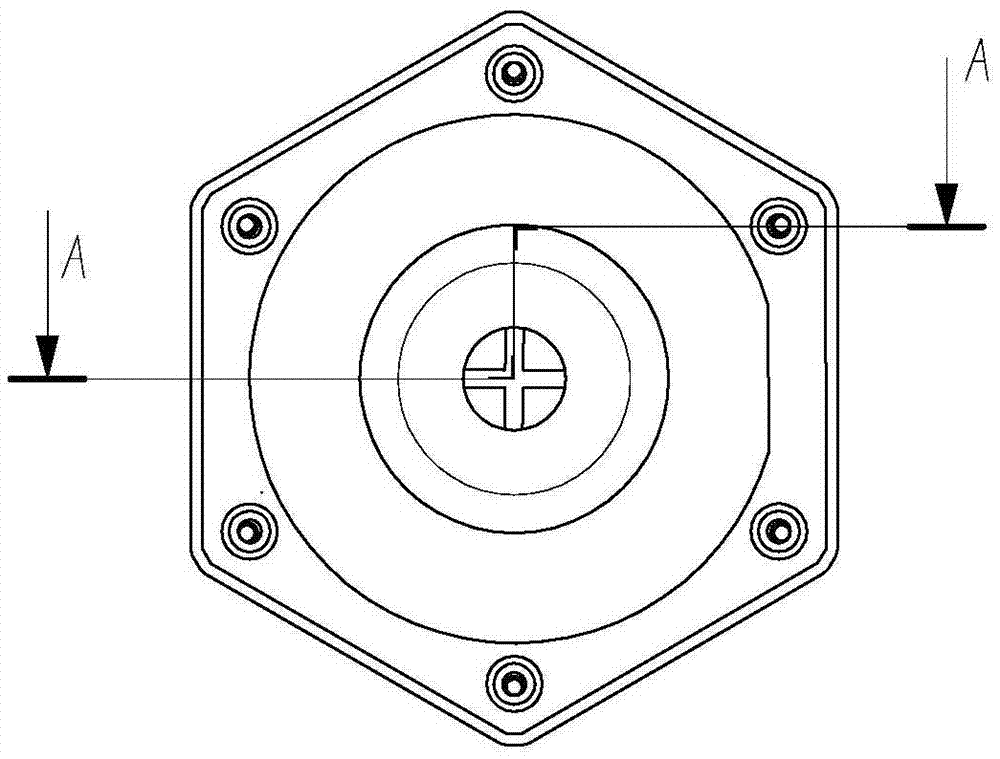

[0019] Example 1: Please refer to figure 1 , figure 2 and image 3 , The explosion-proof, waterproof and breathable valve disclosed in this embodiment includes a valve body 1 and a cover 2 buckled on the valve body 1. The buckling of the valve body 1 and the cover 2 forms a cavity 3 inside, in which a cavity 3 is formed. The waterproof and breathable membrane 4 separates the chamber into an inner chamber communicating with the inside of the device and an outer chamber communicating with the outside. The valve body 1 is docked with the corresponding equipment, and the valve body 1 can be provided with a screw interface, which can be fixed with the equipment through threads (bolts or flange structure can also be used to fix the valve body on the equipment), so that the valve body 1 is fixed on On the equipment casing (not shown in the figure), a through hole is opened at the bottom of the valve body 1 to communicate with the inside of the equipment.

[0020] A slidable sliding rin...

Embodiment 2

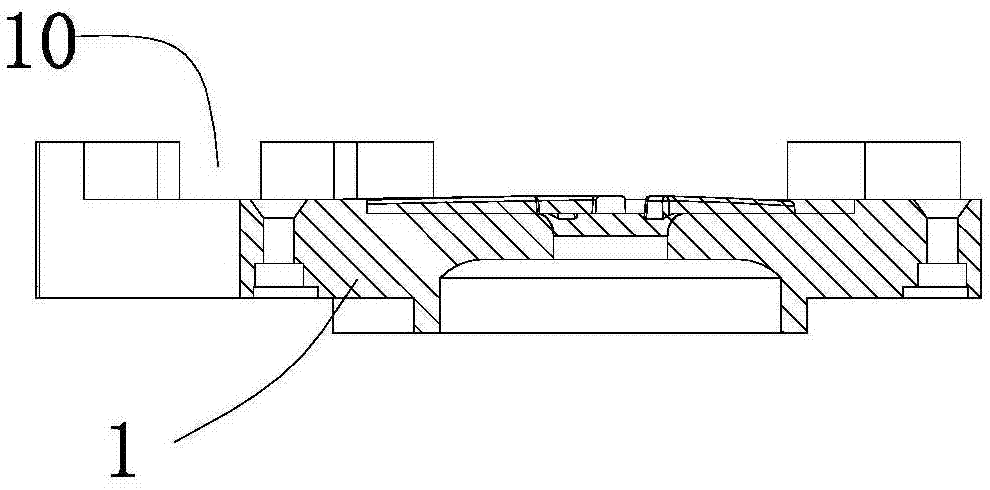

[0030] As attached Figure 4 , Figure 5 Shown. For the explosion-proof, waterproof and breathable valve disclosed in this embodiment, the difference between this embodiment and the first embodiment is that the pressure relief hole 10 is provided with the end of the cover 2 and the outer end of the cover 2 is provided with an outwardly extending pipe joint 11. It is convenient to connect external pipes. In this structure, in order to obtain instant release when the internal pressure of the equipment exceeds a safe value, a ventilation channel 51 is provided on the outer wall of the main ring 5. When the equipment pressure exceeds the safe value, the sliding ring assembly, waterproof rubber ring 8 and waterproof The breathable membrane 4 moves toward the outer chamber under the action of the internal pressure of the device, the waterproof rubber ring 8 is separated from the inner end surface of the valve body 1, and the inside of the device passes through the gap between the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com