Full-automatic labelling system

A fully automatic, labeling technology, applied in the textile field, can solve the problems of high labor cost, low operation efficiency, uneven labeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

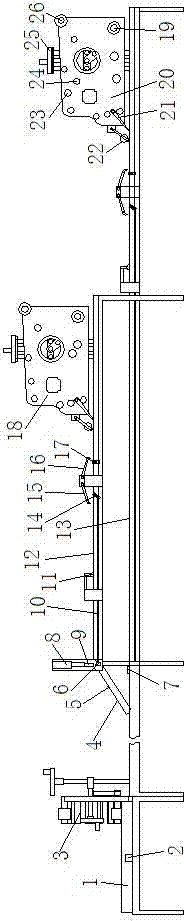

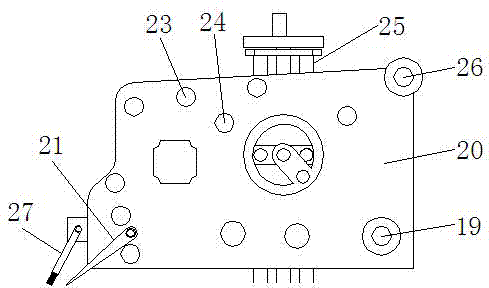

[0018] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

[0019] Waist seal labeling: that is, at both ends of the textile, the trademark is split and pasted on the upper surface, end surface and lower surface of the end.

[0020] Flat labeling: that is, to paste the trademark flatly on the surface of the textile.

[0021] A fully automatic labeling system, as shown in the figure, includes a girdle labeling part 18 that cooperates with a conveyor belt. The girdle labeling part 18 includes a power device and a trademark unrolling mechanism driven by the power device. The running direction of the conveyor belt is described, and a label brushing mechanism is provided in the middle of the front of the trademark unwinding mechanism.

[0022] In order to improve work efficiency, it is preferable to be provided with two laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com