Processing method for thin encapsulation substrate positioning hole

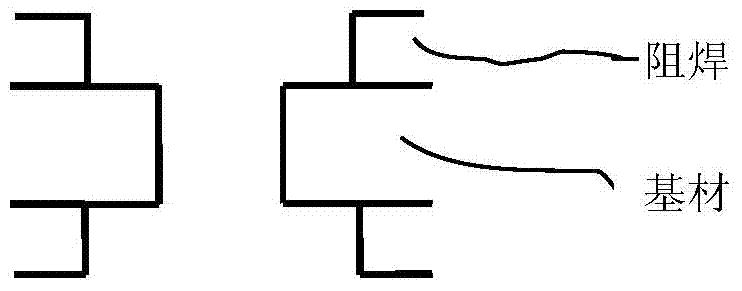

A processing method and technology for positioning holes, which are applied in metal processing and other directions, can solve problems such as easy damage, affect production yield, and unacceptable quality, increase overall thickness, improve damage problems, and avoid solder mask cracks or substrates. glitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present application will be further elaborated below through specific examples.

[0033] In this embodiment, a processing method for positioning holes of a packaging base sheet, the preparation method of the packaging base sheet includes the following steps: drilling, electroplating, outer layer photoimaging, solder masking, gold plating, and contouring processes; the packaging base sheet Thickness≤0.2mm.

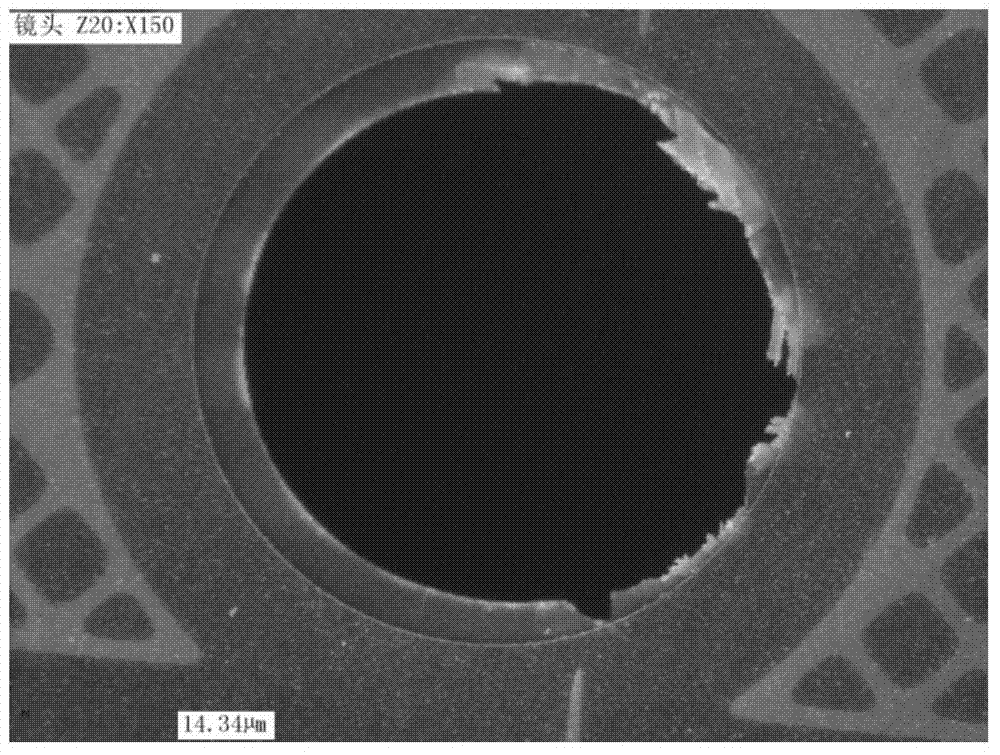

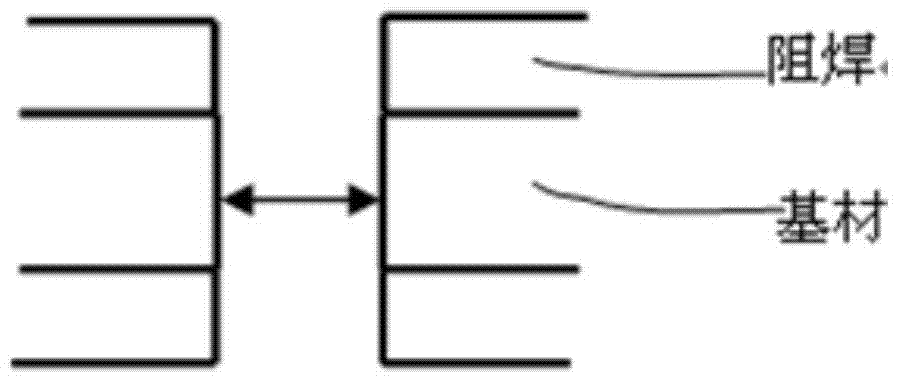

[0034] The processing method of positioning hole comprises the following steps (as image 3 shown):

[0035] Making positioning hole targets: in the outer photoimaging or solder mask process, making targets at the positions of the positioning holes on the board surface; the number of the targets matches the number of positioning holes;

[0036] Positioning hole processing: In the shape process, a punching machine is used to process positioning holes.

[0037] The steps of the punching machine processing positioning holes are:

[0038] The CCD (optical lens) o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com