Hydro-thermal synthetic method and application of Pt-Ru bimetal nanoparticles

A bimetallic nano and hydrothermal synthesis technology, applied in the field of catalysis, can solve the problem of inability to synthesize stable face-centered cubic phase Ru nanoparticles, and achieve the effect of overcoming the low selectivity of alkenes and alkanes, high activity and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

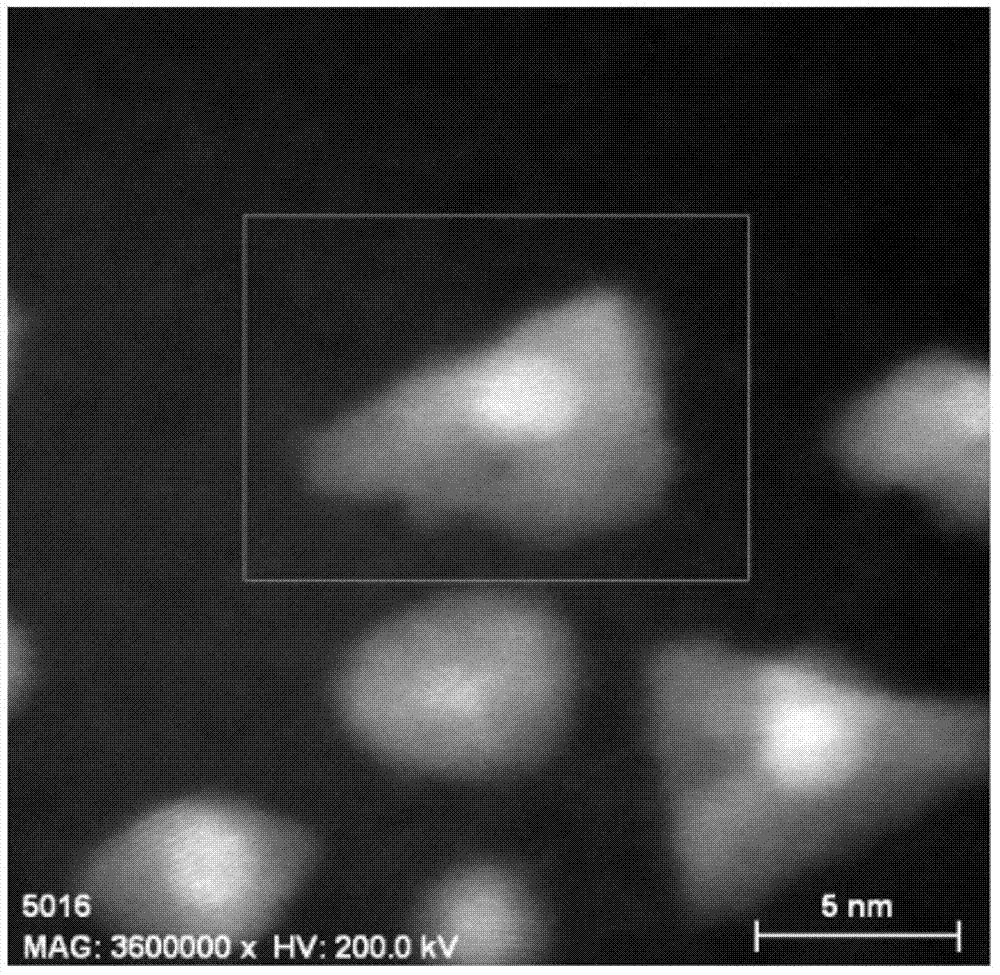

[0030] Synthesis of embodiment 1 Pt-Ru nanoparticles (without adding surface adsorbent)

[0031] Dissolve 0.01 g of platinum precursor salt potassium chloroplatinite and 0.064 g of ruthenium trichloride in 15 mL of water, and simultaneously add 0.1 g of PVP, 0.2 mL of aqueous formaldehyde (mass fraction 40%), 0.065 mL of hydrochloric acid (1mol L -1 ). Transfer the solution to a hydrothermal kettle. Raise the temperature to 160° C. and reduce for 8 hours to prepare 10 wt % Pt-Ru nanoparticles with an average particle diameter of 5±20 nm.

[0032] The morphology of the Pt-Ru bimetallic nanoparticles synthesized in the present invention is observed by using a dark field scanning transmission mode of a 200keV transmission electron microscope.

[0033] The preparation method of the transmission electron microscope sample is as follows: add a small amount of acetone or ethanol to the Pt-Ru nanoparticle dispersion taken out of the hydrothermal kettle, and use ultrasonic dispersion...

Embodiment 2

[0038] Synthesis of embodiment 2 Pt-Ru nanoparticles (adding potassium bromide surface adsorbent)

[0039] Dissolve 0.01 g of platinum precursor salt potassium chloroplatinite and 0.064 g of ruthenium trichloride in 15 mL of water, and simultaneously add 0.1 g of PVP, 0.2 mL of aqueous formaldehyde (mass fraction 40%), 0.065 mL of hydrochloric acid (1mol L -1 ), 1 g potassium bromide. Transfer the solution to a hydrothermal kettle. Heating up to 160°C and reducing for 8 hours, spherical 10wt% Pt-Ru nanoparticles were prepared, and its electron micrograph is as follows: figure 2 Shown, the X-ray diffraction spectrum is shown in Figure 5 .

Embodiment 3

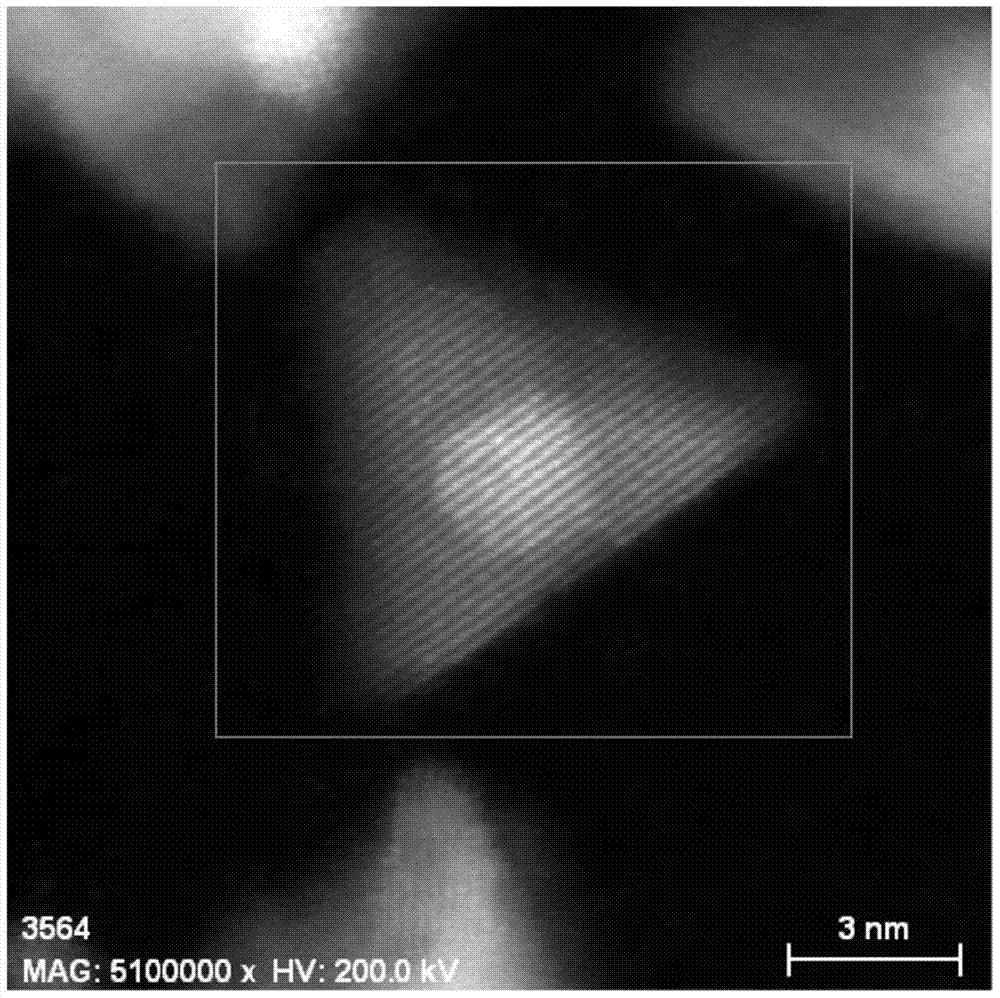

[0040]Synthesis of embodiment 3 Pt-Ru nanoparticles (adding sodium oxalate surface adsorbent)

[0041] Dissolve 0.01 g of platinum precursor salt potassium chloroplatinite and 0.064 g of ruthenium trichloride in 15 mL of water, and simultaneously add 0.1 g of PVP, 0.2 mL of aqueous formaldehyde (mass fraction 40%), 0.065 mL of hydrochloric acid (1mol L -1 ), 80mg sodium oxalate. Transfer the solution to a hydrothermal kettle. Heating up to 160°C and reducing for 8 hours, tetrahedral 10wt% Pt-Ru nanoparticles were prepared, the electron micrographs of which are shown in image 3 Shown, the X-ray diffraction spectrum is shown in Figure 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com