Calcium carbide crushing method

A crushing method and calcium carbide technology, applied in grain processing and other directions, can solve the problem of inability to crush calcium carbide grains below 3mm, and achieve the effect of easy adjustment and control, simple principle, and avoidance of equipment damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

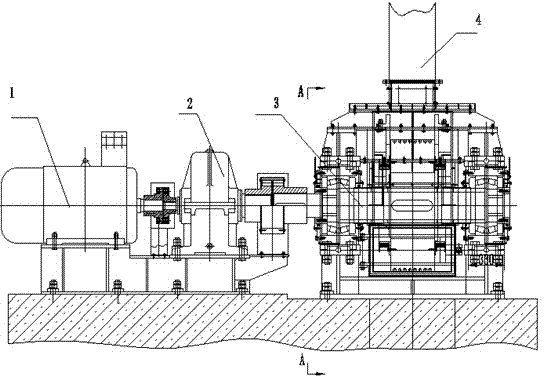

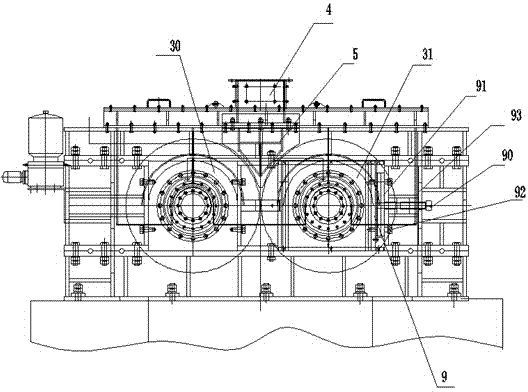

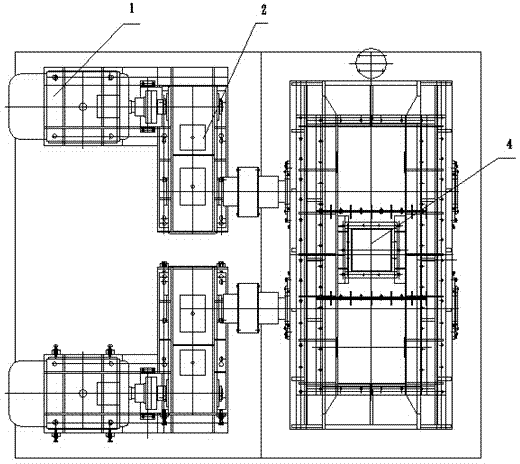

Image

Examples

Embodiment 1

[0043] A. Material selection

[0044] Choose 25mm calcium carbide;

[0045] B. In addition to impurities

[0046] Use iron removal equipment to remove iron impurities contained in calcium carbide, and the content of iron impurities after removal is 0.8%;

[0047] C, broken

[0048] Use a toothed roller crusher to crush the removed calcium carbide. The diameter of the crushing roller is 1400mm, and the length of the crushing roller is 500mm. One of the crushing rollers rotates at 40r / min, and the other is 42r / min. The gap between the crushing rollers is 8mm, and the flow rate of calcium carbide passing between the (two) crushing rollers is 100t / h.

[0049] The crushing roller needs to be lubricated during the crushing. When lubricating, the oil should be injected once every hour, and the oil injection time is 6~10 minutes. The lubricating oil is extreme pressure lithium grease, and the consistency of the lubricating oil is level 2. The bearing temperature is lower than 45℃, and the bear...

Embodiment 2

[0052] A. Material selection

[0053] Select calcium carbide with a particle size of 20mm;

[0054] B. In addition to impurities

[0055] Use iron removal equipment to remove iron impurities contained in calcium carbide, and the content of iron impurities after removal is 0.7%;

[0056] C, broken

[0057] Use a toothed roller crusher to crush the removed calcium carbide. The diameter of the crushing roller is 1100mm, and the length of the crushing roller is 400mm. One of the crushing rollers rotates at 45r / min and the other is 38r / min. The gap between the crushing rollers is 18mm, and the flow rate of calcium carbide passing between the crushing rollers is 120t / h.

[0058] The crushing roller needs to be lubricated during the crushing. When lubricating, the oil should be injected once every hour, and the oil injection time is 6~10 minutes. The lubricating oil is extreme pressure lithium grease, and the consistency of the lubricating oil is level 2. The bearing temperature is lower than...

Embodiment 3

[0061] A. Material selection

[0062] Choose 15mm calcium carbide;

[0063] B. In addition to impurities

[0064] Use iron removal equipment to remove iron impurities contained in calcium carbide, and the iron impurities content after removal is 0.6%;

[0065] C, broken

[0066] Use a toothed roller crusher to crush the removed calcium carbide. The diameter of the crushing roller is 1200mm, and the length of the crushing roller is 350mm. One of the crushing rollers is rotating at 46r / min, and the other is at 44r / min. The gap between the crushing rolls is 20mm, and the flow rate of calcium carbide passing between the crushing rolls is 150 t / h.

[0067] The crushing roller needs to be lubricated during the crushing. When lubricating, the oil should be injected once every hour, and the oil injection time is 6~10 minutes. The lubricating oil is extreme pressure lithium grease, and the consistency of the lubricating oil is level 2. The bearing temperature is lower than 45℃, and the bearing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com