Random porous curved vane type emulsified oil emulsifying machine of diesel engine

A technology of bending blades and emulsified oil, applied in chemical instruments and methods, mixers, dissolving and other directions, can solve the problems of inability to solve low-load and high-load work, low intermittent production efficiency, poor product stability, etc., to improve the emulsification effect. , low cost, high emulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

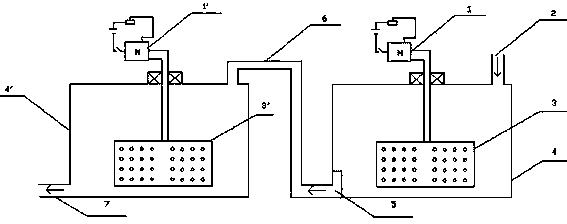

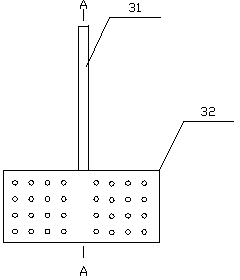

[0014] like figure 1 , image 3 , Figure 4 and Figure 4 Shown: a random porous curved blade emulsifier for diesel emulsified oil, including two first emulsification tanks 4 and second emulsification tanks 4' connected by air pipes 6 with the same structure and principles, and the emulsified oil formed after secondary emulsification The particle size can meet the needs of diesel engines for energy saving and emission reduction; the first emulsification tank 4 and the second emulsification tank 4' are respectively equipped with a first stirring device 3 and a second stirring device 3' for stirring the emulsified oil. A stirring device 3 and a second stirring device 3' are respectively driven by the first drive device 1 and the second drive device 1', and the air inlet 2 and the air outlet 7 are respectively arranged above the first emulsifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com