Moxa holding device, warming moxibustion rod handle and manufacturing method of moxa holding device

A manufacturing method and technology of reserved positions, applied in the direction of heating/cooling reflection point instruments, etc., can solve the problems of high processing cost and complicated process, and achieve the effect of improving service life, expanding diameter range and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

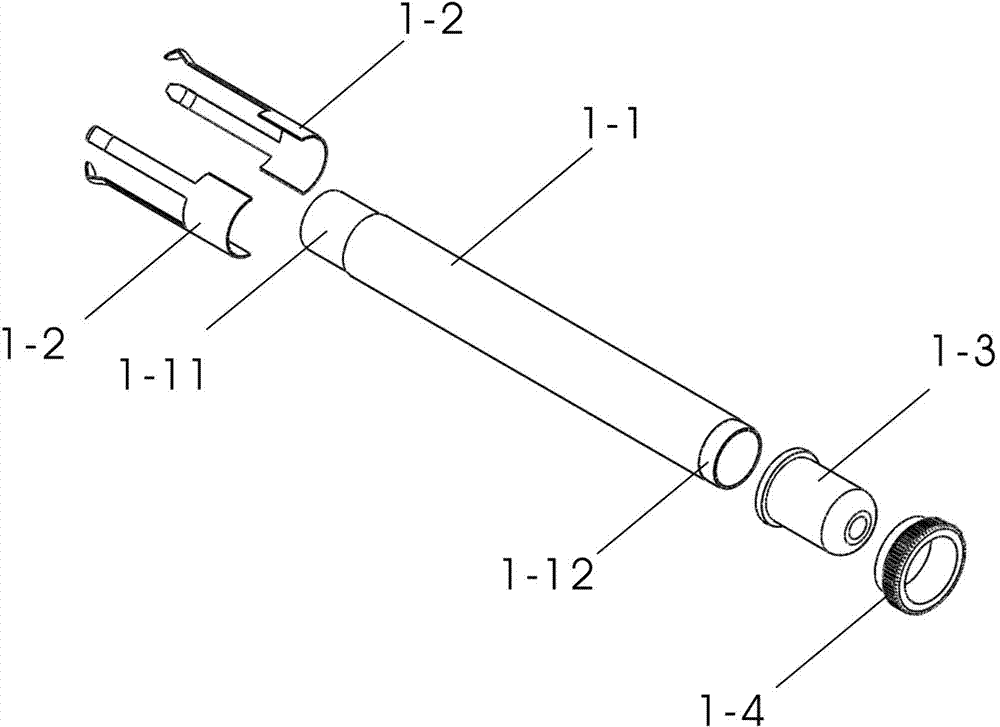

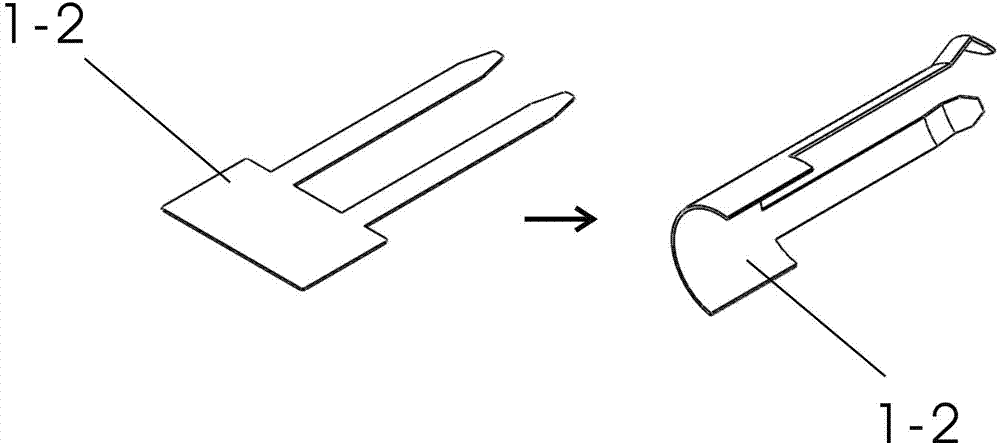

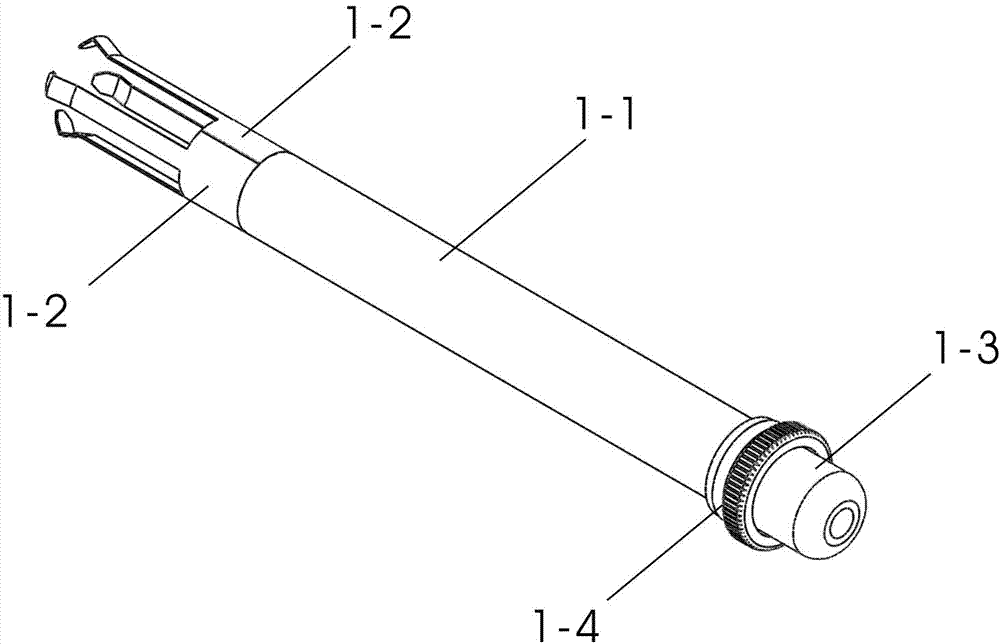

[0029] refer to Figure 1~Figure 3 , a moxa holding device according to a preferred embodiment of the present invention, comprising an independently formed tube body 1-1 and a gripper 1-2, the gripper 1-2 is provided with two pieces and is fixed to the tube body 1 symmetrically and tightly. -1 at the top position 1-11; the end of the gripper 1-2 is bent and the fingertips of the gripper are conical in width gradually narrowing; of course, the number of grippers can also be 1 or more Sheets, the fingertips of the gripper can also be arc-shaped or triangular or tapered in width gradually shrinking.

[0030] In order to facilitate welding, the pipe body 1-1 is made of stainless steel pipe body, and the gripper is also made of stainless steel plate, which is made of hard stainless steel material, which can improve the rebound stability and service life of the gripper 1-2.

[0031] In order to control the telescopic movement of the gripper 1-2, a tailstock 1-3 is fixed at the tail...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com