Non-contact electronic horn using pure aluminum wire drive coil

An electronic horn and wire-driven technology, which is applied in the direction of sound-producing devices and instruments, can solve the problems that the resistivity of aluminum wire is greatly affected by temperature, the aluminum wire is not easy to weld, and the heat generated by resistance is large, so that it can be easily wound into a coil, The effect of stable frequency and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

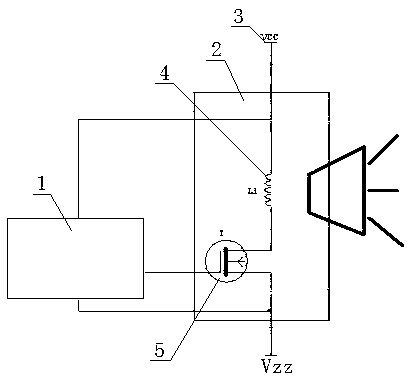

[0013] A non-contact electronic horn using a pure aluminum wire drive coil. The composition includes: a main control circuit 1. The main control circuit is connected to a power module 2, and the power module includes a pure aluminum connected to a car power supply 3. Line drive coil 4, the pure aluminum wire drive coil is connected in series with the switch MOS tube 5, and the main control circuit is connected with the switch MOS tube.

Embodiment 2

[0015] According to the contactless electronic horn using a pure aluminum wire drive coil described in Embodiment 1, one end of the drive coil is connected to a MOS tube, and the other end is connected to the automobile power supply.

Embodiment 3

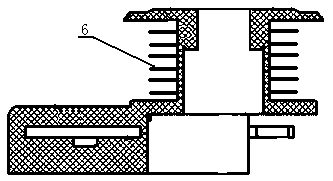

[0017] According to the non-contact electronic horn using the pure aluminum wire drive coil described in embodiment 1 or 2, the coil frame of the pure aluminum wire drive coil has a set of spacers 6, and the spacers are coated with insulation The thickness of the lacquered metal sheet and pure aluminum wire wound on the coil frame does not exceed the height of the spacer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com