Modularized design method for braking system for vehicle

A modular design, braking system technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of not satisfying the efficient design of the braking system, low quality of the braking system, etc., to reduce repetitive work, Improve assembly efficiency and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

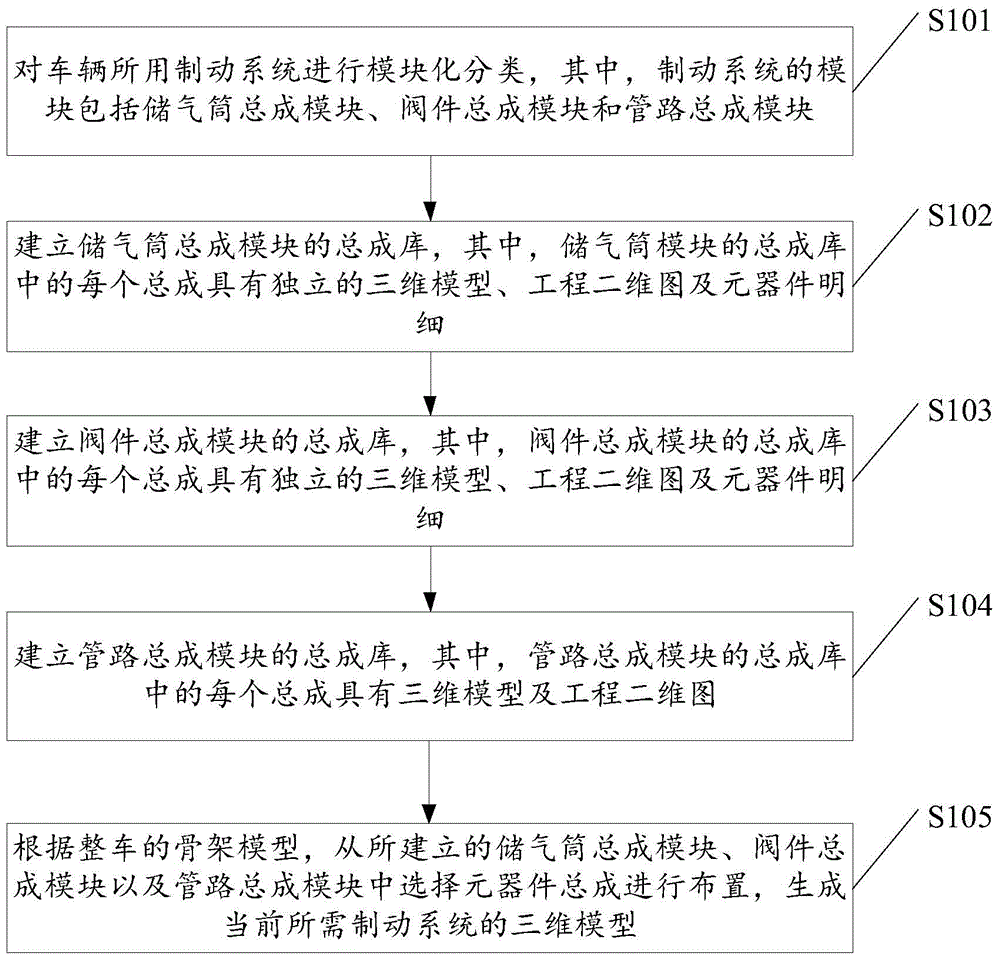

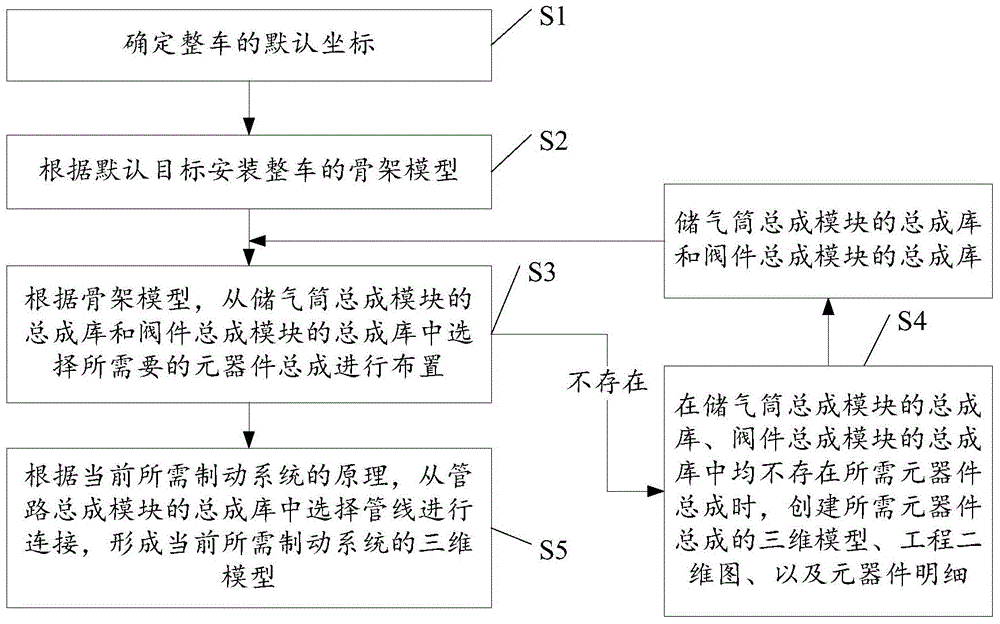

[0024] In order to solve the technical problem that the existing technology cannot satisfy the high-efficiency design of the vehicle braking system, and the quality of the designed vehicle braking system is not high, the embodiment of the present invention provides a modular design of the vehicle braking system method, the general idea is as follows:

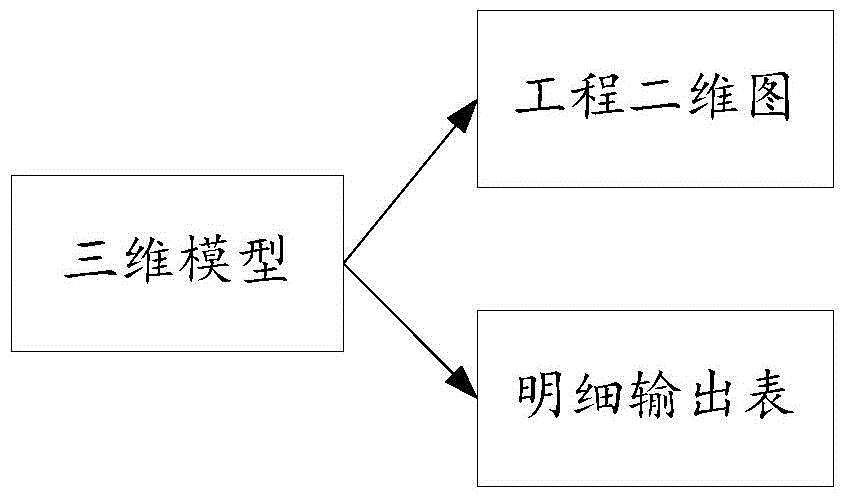

[0025] Using a modular design method, the braking system used by the vehicle is classified into three types: air storage tank assembly module, valve assembly module and optical path assembly module, and an assembly library for the air storage tank assembly module is established. Among them, the air storage tank module Each assembly in the assembly library has an independent three-dimensional model, two-dimensional engineering drawing and component details; the assembly library of the valve assembly module is established, and each assembly library in the valve assembly module Each assembly has an independent 3D model, engineering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com