Box body interlayer water-cooled type small-tooth-difference reducer box of heavy duty plate feeder

A technology of apron feeder and reduction box, which is used in mechanical equipment, gear transmission, gear lubrication/cooling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

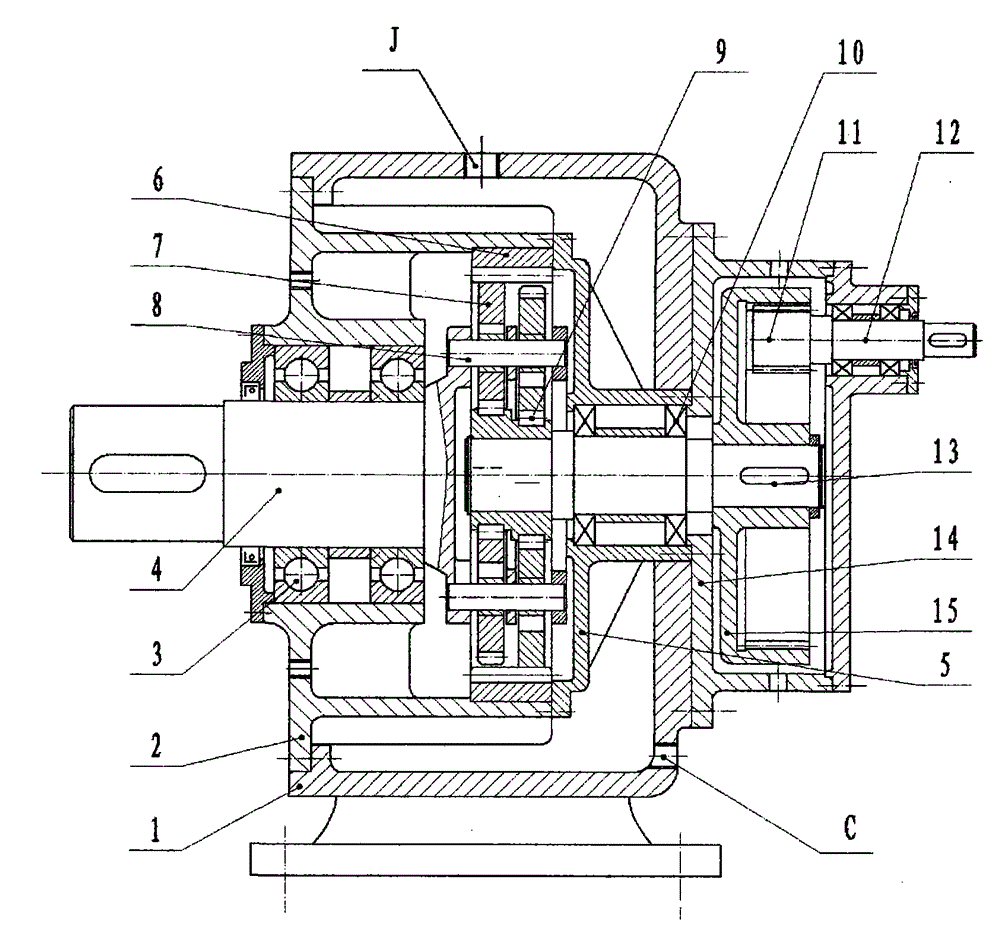

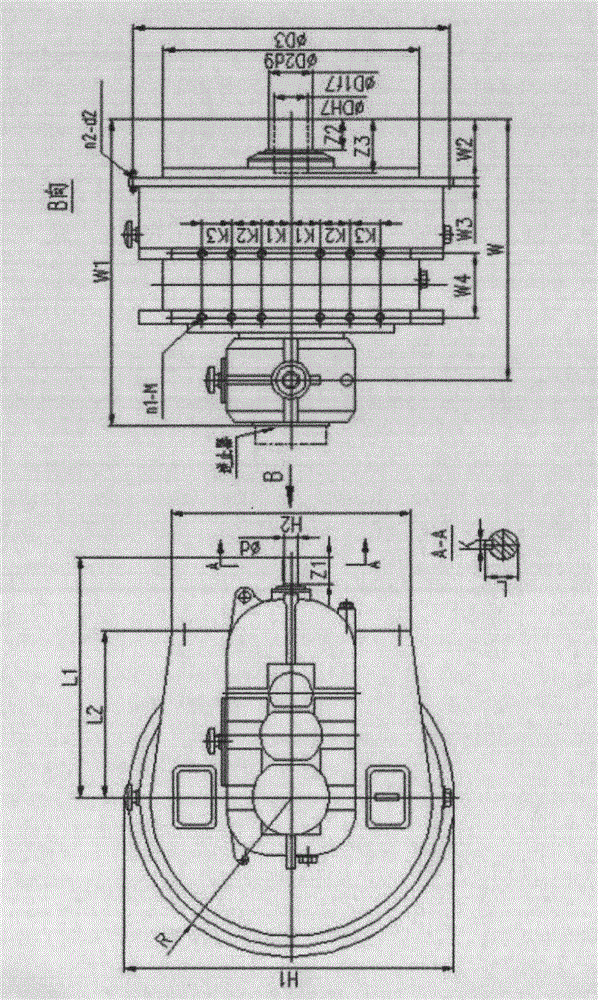

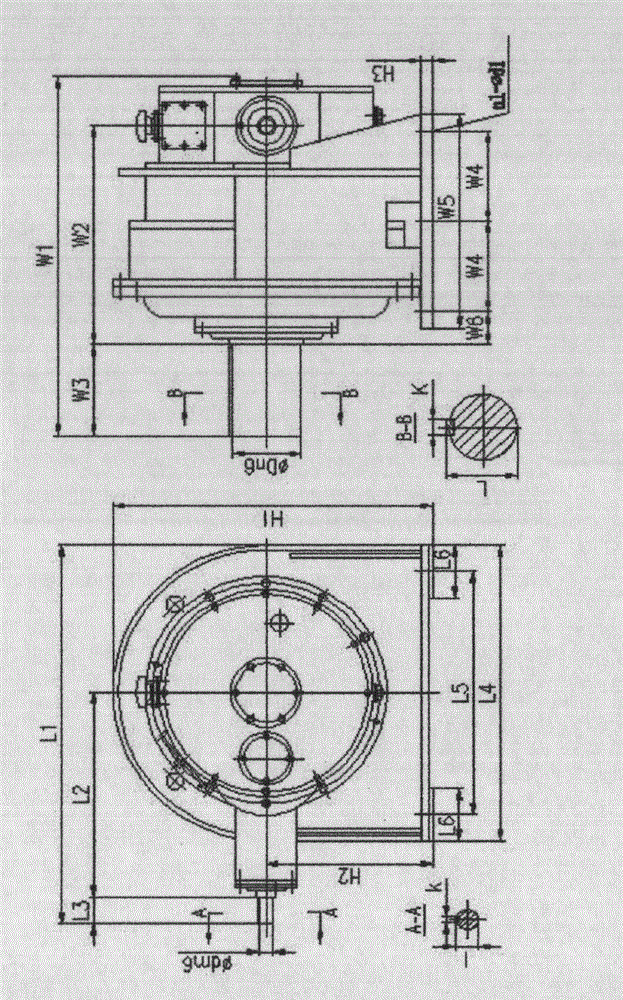

[0042] The present invention is described in detail below in conjunction with accompanying drawing:

[0043] refer to figure 1 . A box interlayer water-cooled heavy-duty apron feeder gear box with less tooth difference, comprising a box body 1 and an input shaft 13 arranged in the box body 1 and sequentially driven, a transmission mechanism and an output shaft 4, characterized in that:

[0044] The box body 1 is provided with a connecting piece between the inner cylinder 2 and the round end cover 5, the flange of the inner cylinder 2 is connected to the output end surface of the box body 1, and the outer circle of the input end of the round end cover 5 is connected to the box body. The inner hole of the input end of the body 1 is tightly matched, and the input end faces of the round end cover 5 and the box body 1 are sealed and connected with the end face of the modular round shell 14 at the same time, and the connection between the built-in cylinder 2 and the round end cover ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap