A vehicle heat dissipation system and control method for matching a hydraulic retarder

A technology of heat dissipation system and control method, which is applied in the direction of coolant flow control, power unit cooling combination arrangement, power unit, etc., and can solve the problems of increasing the fuel consumption of the whole vehicle, the range of increase is not large, and the effect is limited. Achieve the effect of simple control method, accurate control and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] Take the application of this scheme in the retarder waterway as an example to illustrate. The retarder is an auxiliary braking device for the whole vehicle, which converts kinetic energy into heat energy during braking, and finally dissipates the heat into the air through the vehicle cooling system. The heat dissipation of the vehicle determines the braking power of the hydraulic retarder.

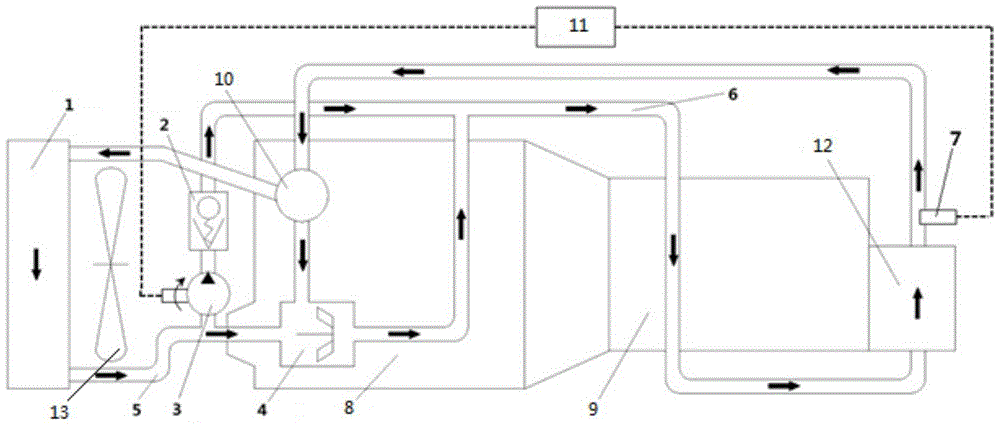

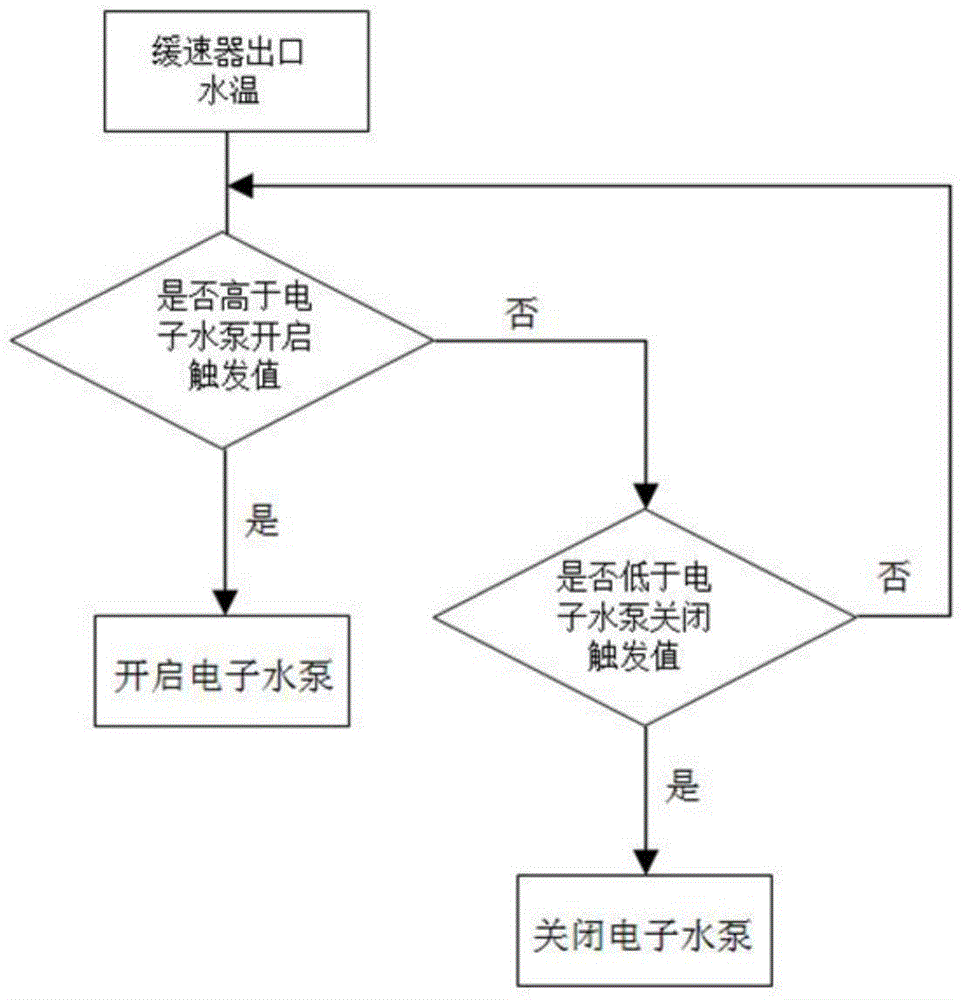

[0031] Such as figure 1 As shown, a vehicle heat dissipation system for matching the hydraulic retarder is connected with the engine 8 and the transmission 9; it includes a cooling circuit system, an electronic water pump 3, a water temperature sensor 7 and a control module 11, and the cooling circuit system Including cooling water tank 1, original car water pump 4, engine water inlet pipe 5 and engine water outlet pipe 6; The water outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com