Spray-free baking varnish metal-like polypropylene material and preparation method thereof

A technology of polypropylene material and metal imitation, which is applied in the field of spray-free baking paint imitation metal polypropylene material and its preparation to achieve a beautiful metal imitation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

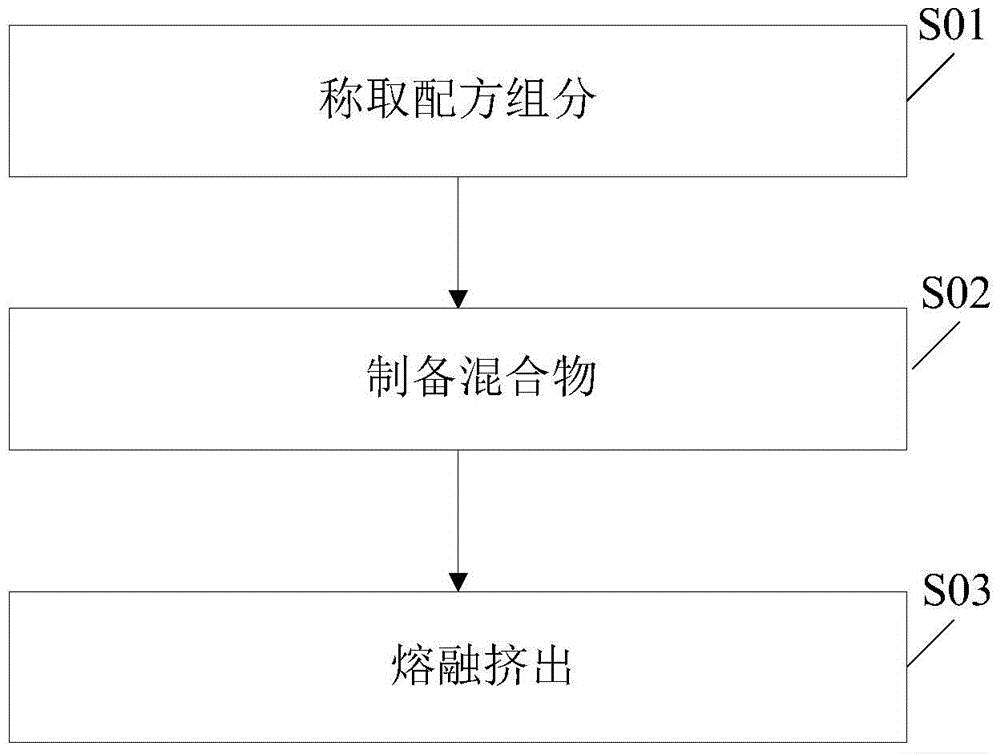

[0034] Correspondingly, an embodiment of the present invention provides a method for preparing a non-spray baking varnish imitation metal polypropylene material, comprising the following steps:

[0035] (1) Weigh the formula components

[0036] Weigh the polypropylene, polypropylene compatibilizer, nucleating agent, lubricant and antioxidant respectively according to the above-mentioned non-spray baking paint imitation metal polypropylene material formula;

[0037] (2) Prepare the mixture

[0038] Mix the polypropylene, polypropylene compatibilizer, nucleating agent, lubricant and antioxidant weighed in step (1) into a low-speed mixer and mix for 3 to 5 minutes, and mix well to obtain a mixture;

[0039] (3) Melt extrusion

[0040] The mixture obtained in step (2) is fed into the twin-screw extruder from the main feeding system, and then the composite metal powder is fed into the twin-screw extruder from the side feeding system, and melted and extruded and granulated to obta...

Embodiment 1

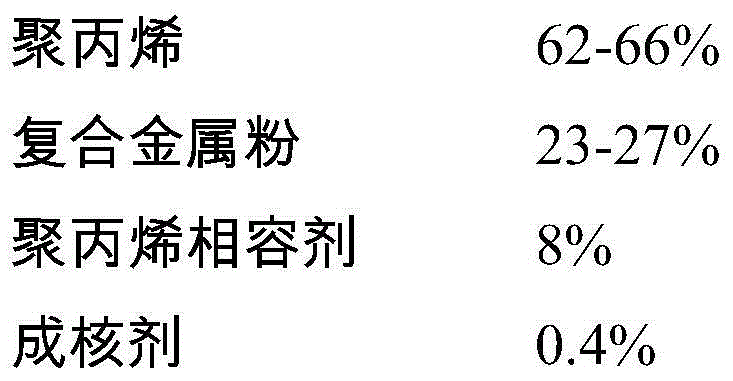

[0049] The spray-free stoving paint imitation metal polypropylene material of this embodiment is made up of the following components by weight: 62% polypropylene, 8% polypropylene compatibilizer, 0.4% nucleating agent, 2% lubricant, composite metal powder 27% and antioxidant 0.6%;

[0050] Its preparation method is as follows:

[0051] (1) take each component by above-mentioned parts by weight;

[0052] (2) adding the polypropylene, polypropylene compatibilizer, nucleating agent, lubricant and antioxidant weighed in step (1) to a low-speed mixer and mixing for 4 minutes, mixing fully to obtain a mixture;

[0053] (3) Add the mixture obtained in step (2) into the twin-screw extruder from the main feeding system, then add the composite metal powder into the twin-screw extruder from the side feeding system, and melt extrude and granulate , to obtain spray-free baking paint imitation metal polypropylene material, the process conditions are: the temperature of the first zone is 2...

Embodiment 2

[0055] The non-spray baking paint imitation metal polypropylene material of this embodiment is made up of the following components by weight: 66% polypropylene, 8% polypropylene compatibilizer, 0.4% nucleating agent, 2% lubricant, composite metal powder 23% and antioxidant 0.6%;

[0056] Its preparation method is as follows:

[0057] (1) take each component by above-mentioned parts by weight;

[0058] (2) adding the polypropylene, polypropylene compatibilizer, nucleating agent, lubricant and antioxidant weighed in step (1) to a low-speed mixer and mixing for 4 minutes, mixing fully to obtain a mixture;

[0059] (3) Add the mixture obtained in step (2) into the twin-screw extruder from the main feeding system, then add the composite metal powder into the twin-screw extruder from the side feeding system, and melt extrude and granulate , to obtain spray-free baking paint imitation metal polypropylene material, the process conditions are: the temperature of the first zone is 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com