Secondary black liquor treatment method

A treatment method and black liquor technology, applied in water/sewage treatment, aerobic process treatment, anaerobic digestion treatment, etc., can solve the problems of large output of secondary black liquor, waste of raw material resources for treatment, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

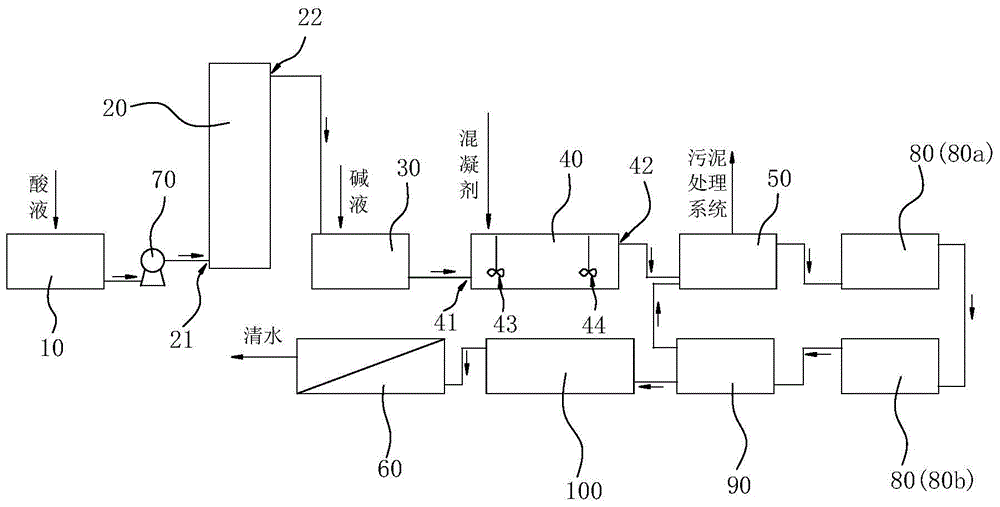

[0017] 1) if figure 1 As shown, the daily processing capacity of the secondary black liquor produced by washing sandalwood bark is 300m 3 In this method, the secondary black liquor is introduced into the acidic regulating tank 10, then in the acidic regulating pond 10, concentrated sulfuric acid is added until the pH value of the secondary black liquor is 3-4, and the acidified secondary black liquor is obtained;

[0018] 2) The acidified secondary black liquor is sent to the liquid inlet 21 in the anaerobic reactor 20 through the water pump 70. Under the condition of 20-25°C, the secondary black liquor contacts with the anaerobic bacteria in the anaerobic reactor 20 to undergo a biochemical degradation reaction, The sewage produced by the biochemical reaction is discharged from the liquid outlet 22 of the anaerobic reactor 20 and enters the neutral adjustment tank 30, and sodium hydroxide solution is added to the neutral adjustment tank 30 to adjust the pH value of the sewage...

Embodiment 2

[0023] 1) if figure 1 As shown, the daily processing capacity of the secondary black liquor produced by washing sandalwood bark is 300m 3 In this method, the secondary black liquor is introduced into the acid regulating tank 10, and then in the acid regulating pond 10, concentrated sulfuric acid is added until the pH value of the secondary black liquor is 3-4 to obtain acidified secondary black liquor;

[0024] 2) The acidified secondary black liquor is sent to the liquid inlet 21 in the anaerobic reactor 20 through the water pump 70. Under the condition of 20-25°C, the secondary black liquor contacts with the anaerobic bacteria in the anaerobic reactor 20 to undergo a biochemical degradation reaction, The sewage produced by the biochemical reaction is discharged from the liquid outlet 22 of the anaerobic reactor 20 and enters the neutral adjustment tank 30, and sodium hydroxide solution is added to the neutral adjustment tank 30 to adjust the pH value of the sewage to 7-8. T...

Embodiment 3

[0028] 1) if figure 1 As shown, the daily processing capacity of the secondary black liquor produced by washing sandalwood bark is 300m 3 In this method, the secondary black liquor is introduced into the acidic regulating tank 10, then in the acidic regulating pond 10, concentrated sulfuric acid is added until the pH value of the secondary black liquor is 3-4, and the acidified secondary black liquor is obtained;

[0029] 2) The acidified secondary black liquor is sent to the liquid inlet 21 in the anaerobic reactor 20 through the water pump 70. Under the condition of 20-25°C, the secondary black liquor contacts with the anaerobic bacteria in the anaerobic reactor 20 to undergo a biochemical degradation reaction, The sewage produced by the biochemical reaction is discharged from the liquid outlet 22 of the anaerobic reactor 20 and enters the neutral adjustment tank 30, and sodium hydroxide solution is added to the neutral adjustment tank 30 to adjust the pH value of the sewage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com