Five-axis machining center coordinate system determination method based on 7-point detection repetition

A technology for machining centers and determining methods, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as time-consuming and labor-intensive, unguaranteed parts processing quality, and low parts processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

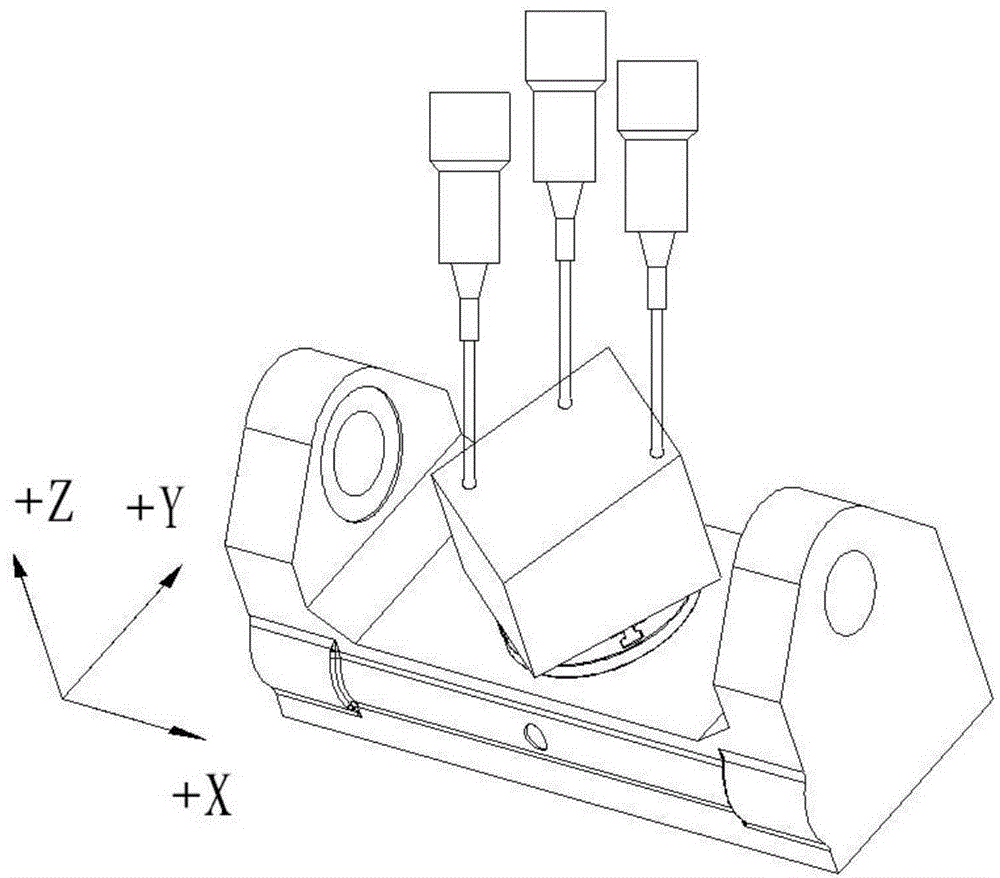

[0023] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] The invention configures an infrared measuring head in the five-coordinate machining center, uses the infrared measuring head to measure the collision point, and calculates according to the mechanical coordinate data of the collision point to obtain the rotation angle of the fourth axis and the fifth axis of the five-coordinate machining center and the rotation angle of each axis The zero point position is finally automatically input into the origin table or preset table to realize the zero point setting.

[0025] In the embodiment of the present invention, the following content is adopted:

[0026] Five coordinate machining center (Hermle C40u),

[0027] HEIDENHAIN control system (iTNC530);

[0028] 3-point measurement of the probe cycle (TCH PROBE 431MEASURE PLANE),

[0029] 3-point measurement of the probe cycle (TCH PROBE 414DATUM INSIDE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com