Machining method of turbine rotor

A processing method and turbine rotor technology, applied in the field of mechanical processing, can solve the problems of turbine rotor coaxiality, roundness, poor rotation accuracy, etc., and achieve the effects of improving processing accuracy, improving coaxiality, and easy alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

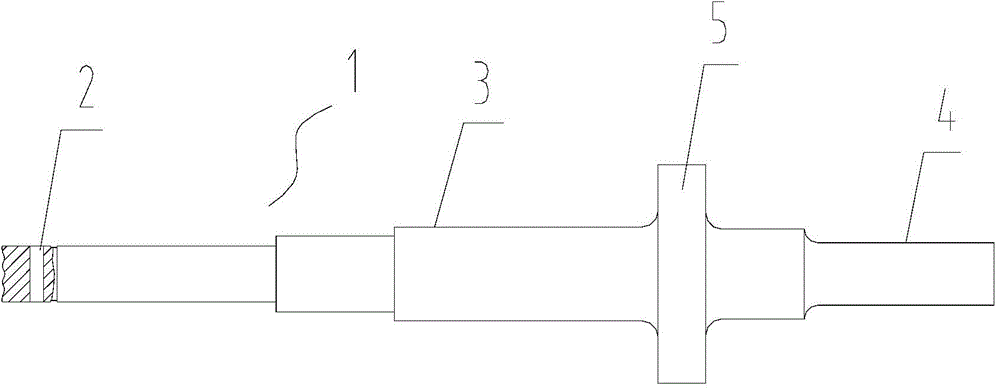

[0071] Such as Figure 1-14 As shown, a method for machining a turbine rotor includes the following steps:

[0072] a. The compressor end 3, the turbine disk 5 and the turbine end 4 of the rough turning turbine shaft 1;

[0073] b. Drill lifting hole 2, the lifting hole is used for hoisting in the subsequent heat treatment process;

[0074] c. Lift the turbine shaft 1 through the lifting hole 2, and perform heat treatment according to the specifications;

[0075] d. The compressor end 3, the turbine disk 5 and the turbine end 4 of the semi-finishing turbine shaft 1;

[0076] e. Grinding the outer circle and end face of the turbine shaft 1;

[0077] f. Align the ground outer circle and end face, finish turning the turbine shaft 1 compressor end 3, turbine disc 5 and turbine end 4;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com