Special powder conveying device for powder forming machine and work process of special powder conveying device

A technology of powder molding machine and powder feeding device, which is applied in the field of powder metallurgy, which can solve the problems of reducing the service life of products, insufficient local strength, and segregation of metal powder, etc., and achieve the effects of increasing service life, improving product quality, and less powder leakage during feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

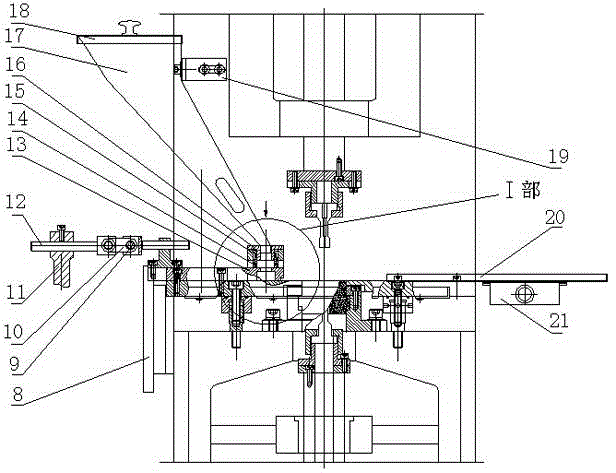

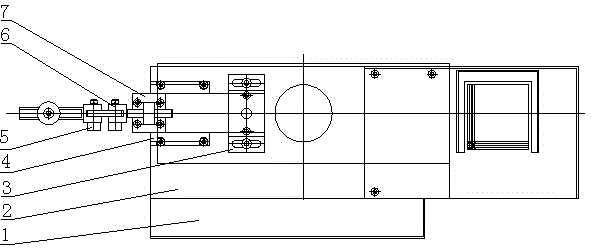

[0024] The powder material box 1 of the present invention includes a template 2, on which a powder feeder 13 that moves left and right along the template 2 is provided, and the powder feeder 13 is provided with a hopper 17 corresponding to the powder feeder 13; The hopper 17 is fixed, the upper part is provided with a hopper cover 18 corresponding to the hopper 17, and is fixed by the hopper bracket 19, the upper and lower parts of the powder feeder 13 are arranged, and the upper part of the powder feeder 13 can move up and down vertically , So that the upper surface of the upper part of the powder feeder 13 can be tightly abutted on the lower surface of the hopper 17.

[0025] The structure of the powder feeder 13 includes: a feeding fixing seat 3, a fixed guide tube 14, a guide plate 16 is sleeved in the guide tube 14, and the guide plate 16 is provided with a powder material hole; The upper part of the guide plate 16 forms an outer flanging, and a compression spring 15 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com