Cutting and flaring positioning plate

A positioning plate and positioning hole technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of thickening and curling of the upper end of the side, and achieve the effect of uniform thickness of the side, good verticality and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

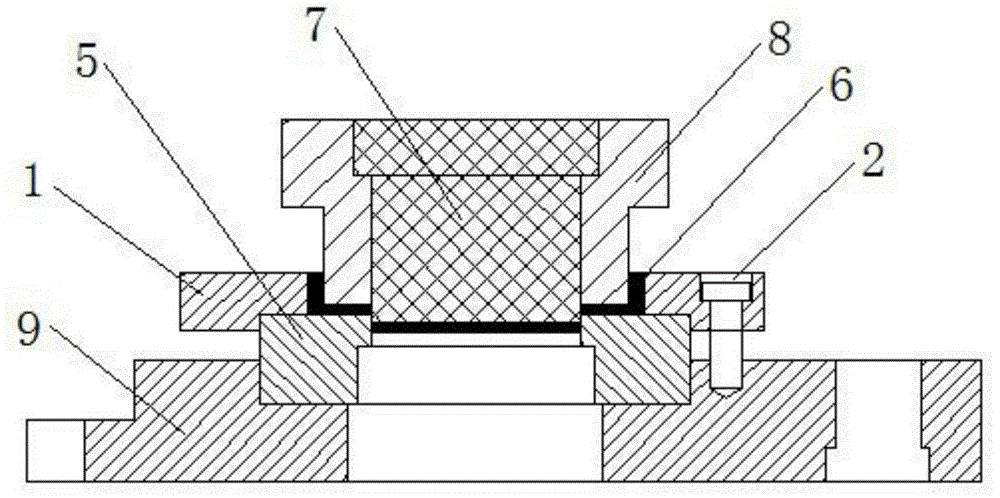

[0013] The present invention is described below in conjunction with accompanying drawing.

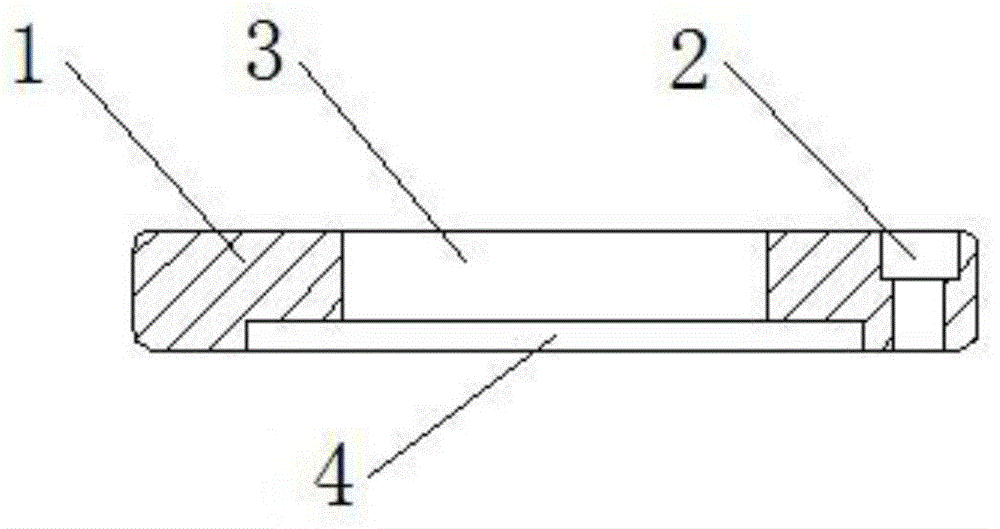

[0014] as attached figure 1 , 2 As shown, the cutting and expanding positioning plate of the present invention is used on the cutting and expanding mold, and the cutting and expanding mold can combine the two processes of bottom cutting and expansion of the frame-shaped cage into one process, and will mainly include a cylindrical plate body 1; the center of the plate body 1 is provided with a positioning hole; the plate body 1 is also provided with at least three bolt through holes 2; the positioning hole is a stepped hole; the positioning hole is divided into a cage forming hole 3 and the die fixing hole 4; the inner diameter of the cage forming hole 3 is equal to the outer diameter of the frame cage 6; the vertical height of the cage forming hole 3 is equal to the height of the frame cage 6.

[0015] Further explanation, the vertical height ratio of the cage forming hole 3 and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com