Vertical roll mill air-distribution process for adjusting cement particle gradation, and device for achieving process

A technology of vertical roller mill and air distribution device, which is applied in grain processing and other directions, can solve the problems of large cyclic load of vertical roller mill, low grinding efficiency of vertical roller mill, and large resistance of vertical roller mill, etc. The effect of power consumption, improving grinding efficiency and reducing cyclic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

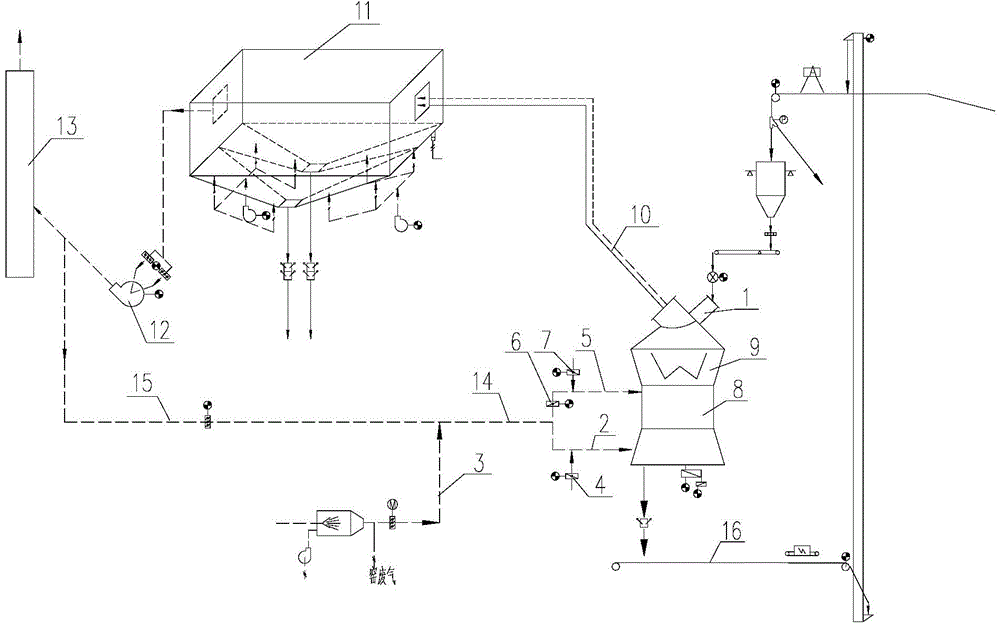

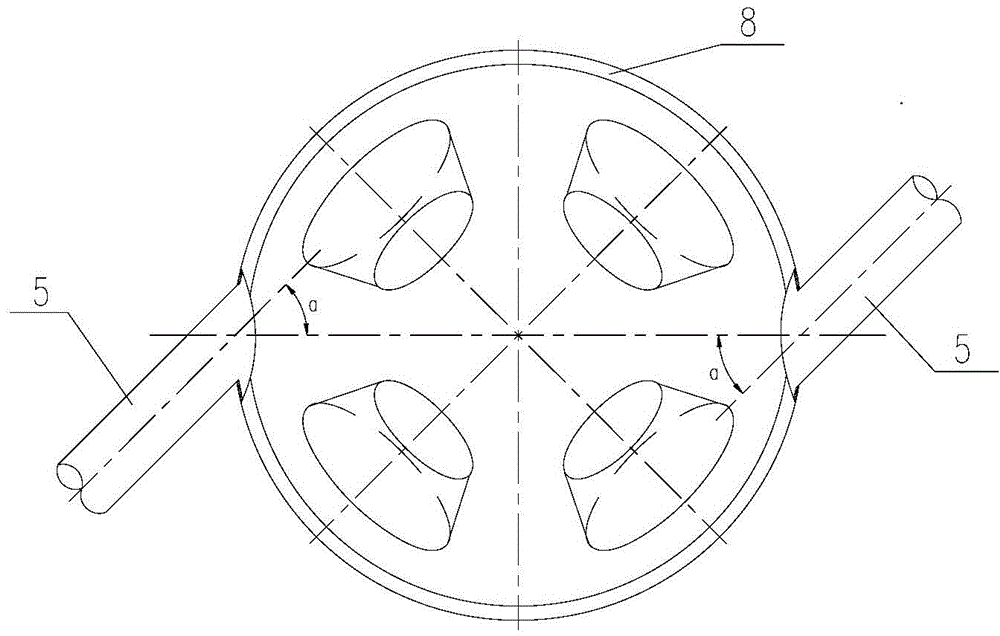

[0018] In order to improve the cyclic load of the vertical roller mill, reduce the resistance of the vertical roller mill, adjust the particle size distribution of the cement product, and then reduce the power consumption of the vertical roller mill, improve the efficiency of the vertical roller mill, and improve the performance of the cement. The invention provides a vertical roller mill air distribution process for adjusting and improving the gradation of cement particles, which divides the air volume required by the vertical roller mill into two parts, one large and one small, and most of them are introduced from the lower part of the vertical roller mill The grinding area is used for lifting and drying the materials in the grinding area. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com