A device for collecting condensate at the top of the flue gas deflector of a wet chimney

The technology of collecting device and guide plate is applied in the field of condensate collecting device at the top of flue gas guide plate of wet chimney. The problems such as condensate on the flue gas deflector are not considered, and the effect of avoiding acid mist deposition, highlighting high efficiency and simple structure is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

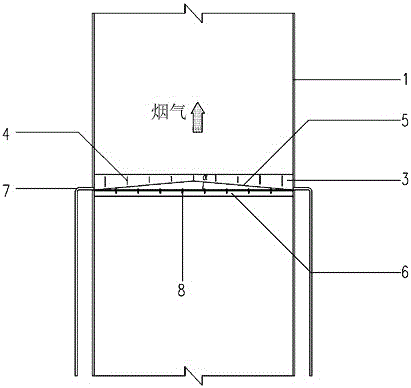

[0048] refer to Figure 1-3 The condensate collecting device at the top of the wet chimney flue gas deflector provided by the present invention includes a fixed bracket 6 and a collecting tank 3, and the collecting tank 3 is arranged along the top of the flue gas deflector 9 through the fixing bracket 6; certainly the collecting tank 3 also It can be directly arranged on the top of the deflector 9 without installing through the fixing bracket 6, and there is no limitation here. The fixed bracket 6 can be fixed with the flue gas guide plate 9 by means of welding or the like, and the collection tank 3 can be connected with the fixed bracket 6 by means of high-strength bolts 8 or welding. Of course, this is only an implementation mode. The flue gas guide The plate 9, the fixed bracket 6, and the collection tank 3 can also be connected by other connection methods, which are not limited here.

[0049] In this embodiment, the length of the fixed bracket 6 and the collection tank 3 ...

Embodiment 2

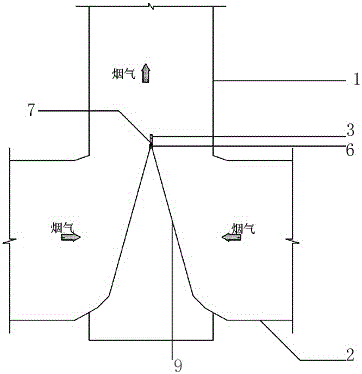

[0056] refer to Figure 4-6 , the wet chimney flue gas deflector top condensate collecting device provided by the present invention comprises a fixed bracket 6 and a collection tank 3, and the collection tank 3 is arranged along the top of the smoke deflector 9 through the fixed bracket 6; A notch is provided on the side, and a water guide plate 5 and a reinforcing plate 4 are arranged in the notch, and a drainage hole and a drainpipe 7 are arranged at the lowest position in the notch.

[0057] In this embodiment, two water guide plates 5 are arranged in the notches on both sides of the collection tank 3, and the two water guide plates 5 are respectively inclined downward from the two ends of the notch to the middle, and the two water guide plates 5 are in the shape of "V" shape; at this time, the middle position of the collection tank 3 is the lowest position, and the middle position of the collection tank 3 is provided with a drain port and a drain pipe 7; condensate is coll...

Embodiment 3

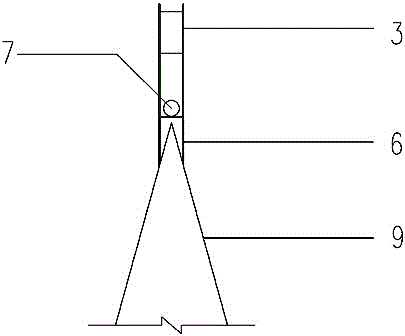

[0060] The device for collecting condensate at the top of the flue gas deflector of the wet chimney provided by the present invention comprises a fixed bracket 6 and a collecting tank 3, and the collecting tank 3 is arranged along the top of the flue gas deflector 9 through the fixing bracket 6; both sides of the collecting tank 3 A notch is arranged on the top, and a reinforcing plate 4 is arranged in the notch, and a drainage hole is opened at the lowest position of the notch and a drainpipe 7 is arranged.

[0061] In this embodiment, the bottoms of the notches on both sides of the collection tank 3 are designed in a "V" or inverted "V" shape; Set at the lowest position in the middle of the bottom of the collecting tank 3; when the bottom of the notch of the collecting tank 3 is in an inverted "V" shape, the lowest positions at both ends of the bottom of the collecting tank 3 are respectively provided with drains and drain pipes 7.

[0062] The difference between this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com