Color metallic orthodontic bracket as well as manufacturing method thereof and composite structure

A technology of orthodontic brackets and colored metals, applied in the direction of brackets, electrolytic coatings, surface reaction electrolytic coatings, etc., can solve the problems of no obvious improvement in appearance and few users of titanium brackets, and achieve excellent biocompatibility Sexuality, keeping the mood happy, and the effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Colorful orthodontic brackets with rainbow effect: The brackets are made of pure titanium grade TA2, and bracket blanks of various tooth positions are prepared according to the route of cutting-forming-welding-polishing-cleaning. The bracket is colored by anodic oxidation method, the electrolyte temperature is 18°C, and the electrolyte is 0.5mol / L H 2 SO 4 +0.5mol / L HCl+deionized water, the oxidation time is 10min, and the brackets of different tooth positions are anodized according to the process parameters in Table 1.

[0029] The process of anodic oxidation reaction is:

[0030] Ti → Ti 2+ ;

[0031] 2H 2 O→O 2 +2H 2 ;

[0032] Ti 2+ +2O 2- →TiO 2 ;

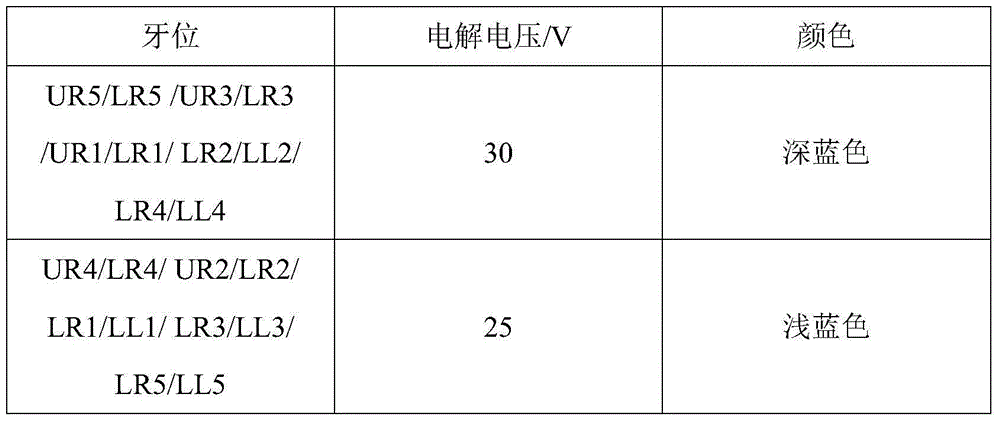

[0033] Table 1 Anodizing parameter list

[0034] tooth position

[0035] According to the order of the rainbow colors according to the arrangement of the teeth, the colorful brackets with rainbow effects can be obtained after combination packaging.

Embodiment 2

[0037] Colored orthodontic brackets with wave effect: The brackets are made of titanium alloy grade TC4, and bracket blanks of various tooth positions are prepared according to the route of cutting-forming-welding-polishing-cleaning. The bracket is colored by anodic oxidation method, the electrolyte temperature is 20°C, and the electrolyte is 0.5mol / L H 2 SO 4 +0.2mol / L of H 3 PO 4 + Deionized water, the oxidation time is 10 minutes, and the brackets of different tooth positions are anodized according to the process parameters in Table 2.

[0038] Table 2 Anodizing parameter list

[0039]

[0040] According to the arrangement of the teeth and in the order of the color of the waves, the colorful brackets with the effect of waves can be obtained after combination packaging.

Embodiment 3

[0042] Colored brackets with maple leaf effect: The brackets are made of titanium alloy grade TC4, and bracket blanks for various tooth positions are prepared according to the route of cutting-forming-welding-polishing-cleaning. The bracket is colored by anodic oxidation method, the electrolyte temperature is 18°C, and the electrolyte is 0.5mol / L H 2 SO 4 +0.5mol / L HCl+deionized water, the oxidation time is 10min, and the brackets of different tooth positions are anodized according to the process parameters in Table 3.

[0043] Table 3 Anodizing parameter list

[0044]

[0045] According to the arrangement of the teeth and in the order of the color of the maple leaf, the colored brackets with maple leaf effect can be obtained after combination packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com