A rice precision water direct seeding machine

A direct-broadcasting machine and precision technology, applied in the fields of planter parts, spaced quantitative sowing machinery, sustainable manufacturing/processing, etc., can solve the problems of seed washing out, fast traveling speed, unfavorable seeding, etc., and achieve pressing into Stable depth, adjustable seeding rate, and reduced resuction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings.

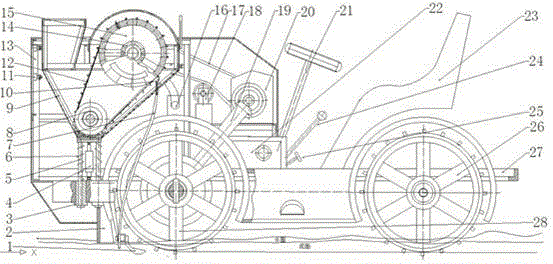

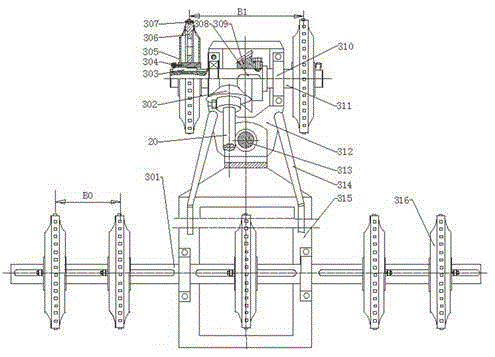

[0037] The structure and working principle of the new pneumatic type rice precision water direct seeding machine according to the present invention are as attached figure 1 shown. The specific structure is mainly composed of a seed metering mechanism and its variable speed transmission system, a narrow-edge multi-wheel set, a live broadcast machine chassis, a seed box and its floating support system, a seeding device, a drive system, and a steering system.

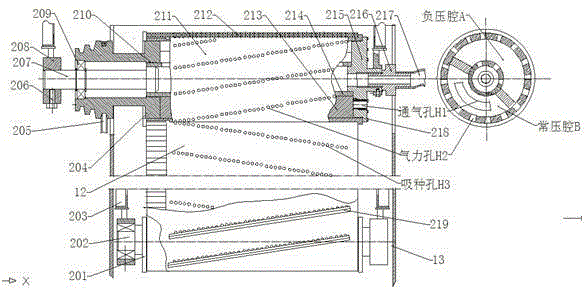

[0038] The seed metering mechanism includes the seed metering belt 12 and the seed metering belt drive wheel assembly 8, the variable speed transmission components (the seed metering mechanism variable speed transmission system 17, the transmission belt tensioning mechanism 18), the seed suction and release drum component 15, the pneumatic shaft and its components 14, Pneumatic device 16 (not fully drawn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com