Self-tuning microwave plasma torch and self-tuning device thereof

A microwave plasma and self-tuning technology, applied in the field of chemical measurement, can solve the problems of unmatched system impedance, cumbersome operation, unfavorable instrument protection, etc., to improve operability and service life, reduce experience requirements, and be conducive to protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

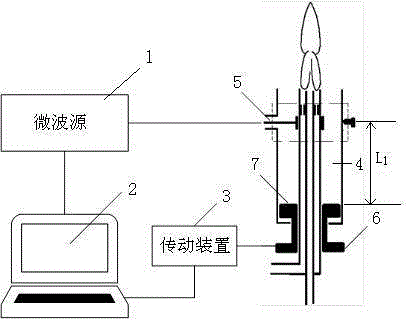

[0038] like figure 1 A self-tuning device for a microwave plasma torch is shown, the microwave plasma torch (4) includes a coupling antenna (5) and an adjustment member (6), characterized in that the device includes a microwave source (1), a control module (2), transmission device (3);

[0039] The microwave source is connected to the coupling antenna (5), the adjustment member (6) is connected to the transmission device (3), the transmission device (3) is connected to the control module (2), and the The control module (2) is connected to the microwave source;

[0040] Wherein, the microwave source generates a microwave electromagnetic field to provide microwave energy for the microwave plasma torch (4), and at the same time obtains the feedback information of the microwave plasma torch (4) from the coupling antenna (5), and the microwave source will reflect the reflected power value in the feedback information Extracted and fed back to the control module (2), the control mo...

Embodiment 2

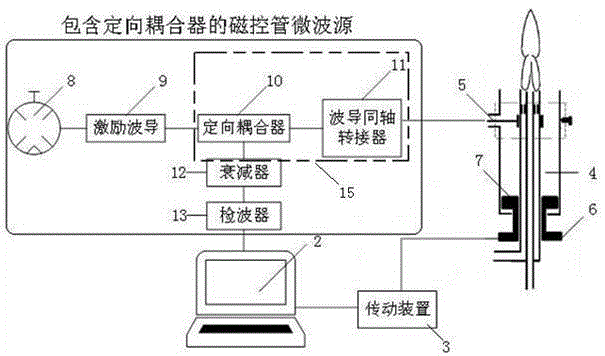

[0050] like image 3 As shown, the microwave source in this embodiment is a magnetron microwave source containing a directional coupler, which includes a magnetron (8), an excitation waveguide (9), an attenuator (12), a detector (13 ), transfer module (15). The magnetron (8) is sequentially connected with the excitation waveguide (9), the adapter module (15), and the coupling antenna (5), and provides microwave energy for the microwave plasma torch (4) while receiving the microwave plasma torch (4) ) feedback information; at the same time, the transfer module (15) is connected to the attenuator (12) and the detector (13) in order to attenuate and transmit the feedback information; the detector (13) is connected to the control module (2 ) connected to extract the reflected power value from the feedback information and transmit it to the control module (2).

[0051] The adapter module (15) in this embodiment includes a directional coupler (10) and a waveguide coaxial adapter (...

Embodiment 3

[0055] like Figure 4 As shown, the microwave source in this embodiment is a magnetron microwave source including a three-port circulator, which includes a magnetron (8), an excitation waveguide (9), an attenuator (12), a detector ( 13), three-port circulator (14). The magnetron (8) is sequentially connected with the excitation waveguide (9), the three-port circulator (14), and the coupling antenna (5), and provides microwave energy for the microwave plasma torch (4) while receiving the microwave plasma torch ( 4) feedback information; at the same time, the three-port circulator (14) is sequentially connected to the attenuator (12) and the detector (13) to attenuate and transmit the feedback information; the detector (13) is connected to the control module (2) are connected, and are used to extract the reflected power value from the feedback information and transmit it to the control module (2).

[0056] Port 1 of the three-port circulator (14) is connected to the excitation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com