X-ray device and ct equipment with the same

An X-ray and electron emission technology, which is applied in X-ray equipment, X-ray tube components, X-ray tubes, etc., can solve the problems of complex production process, low carbon nanotube emission ability and lifespan, and improve the target Density, narrow target distribution spacing, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] (system composition)

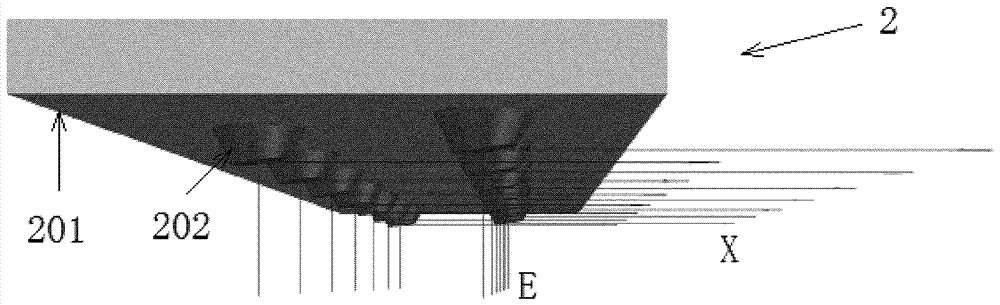

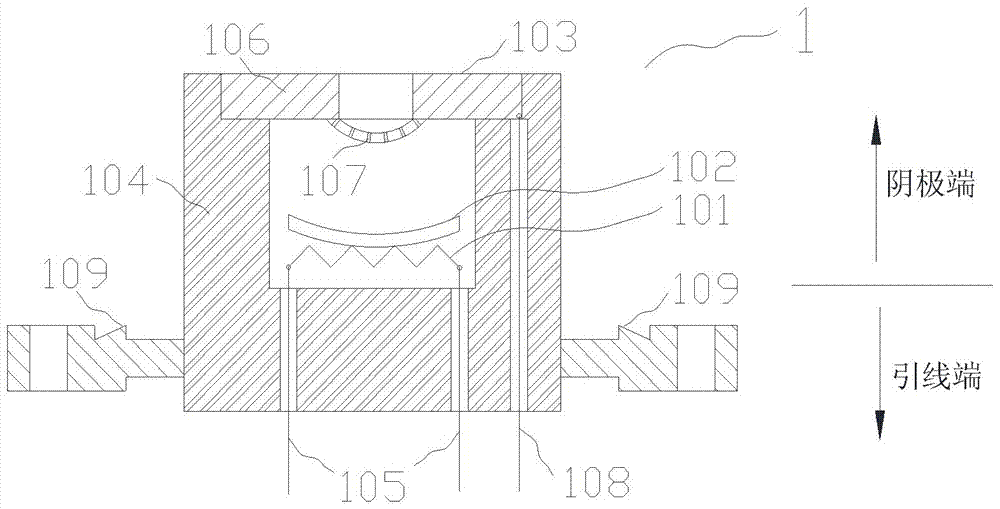

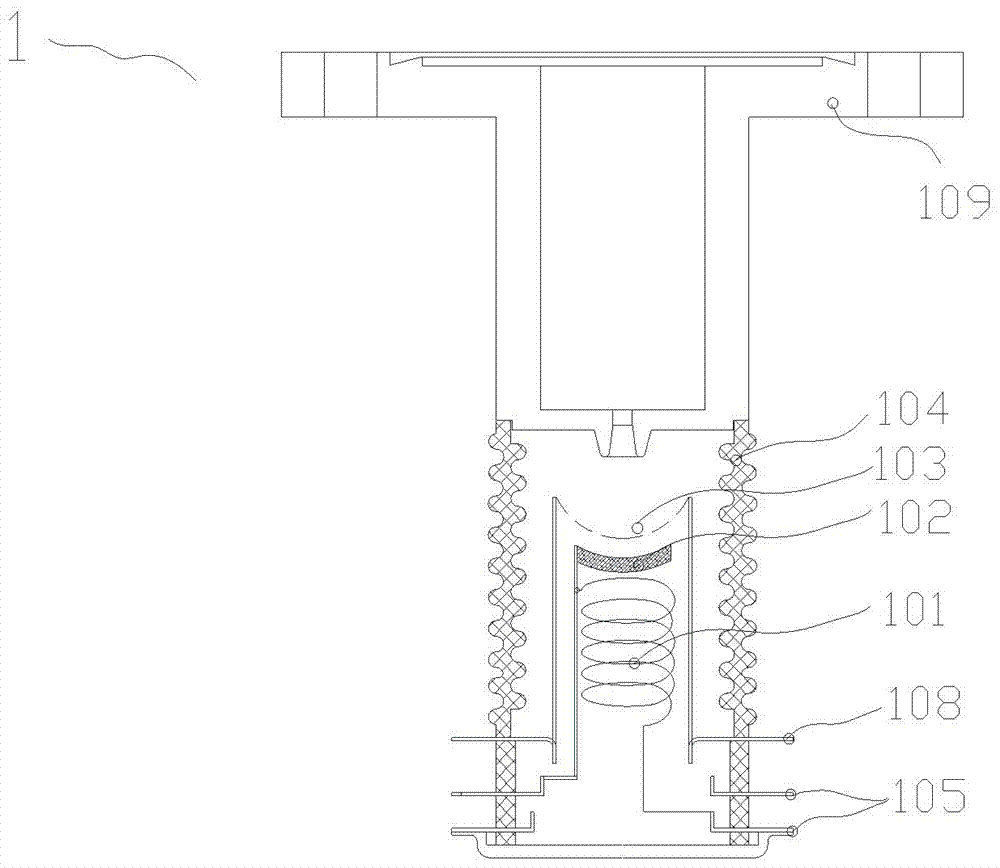

[0093] Such as Figure 1 to Figure 6As shown, the two-dimensional distributed X-ray device consists of a plurality of electron emission units 1, an anode 2, a vacuum box 3, a high-voltage power supply connection device 4, a filament power supply connection device 5, a grid control device connection device 6, a vacuum device 8, and The power supply and control system consists of 7 components. A plurality of electron emission units 1 are arranged on a plane in a two-dimensional arrangement, and are installed on the box wall of the vacuum box 3, each electron emission unit 1 is independent of each other, and the strip-shaped anode 2 is located in the electron emission unit 1 above, installed on the upper end of the vacuum box 3, parallel to the plane where the electron emission unit 1 is located. The electron emission unit 1 includes a filament 101 , a cathode 102 , a grid 103 , an insulating support 104 , a filament lead 105 and a connecting fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com