Horizontal vibration motor

A vibrating motor, horizontal technology, applied in the direction of electrical components, electromechanical devices, etc., can solve the problems of motors prone to noise, affecting the use of mobile phones, long response time, etc., to achieve the effect of using fewer parts, improving vibration effect, and short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

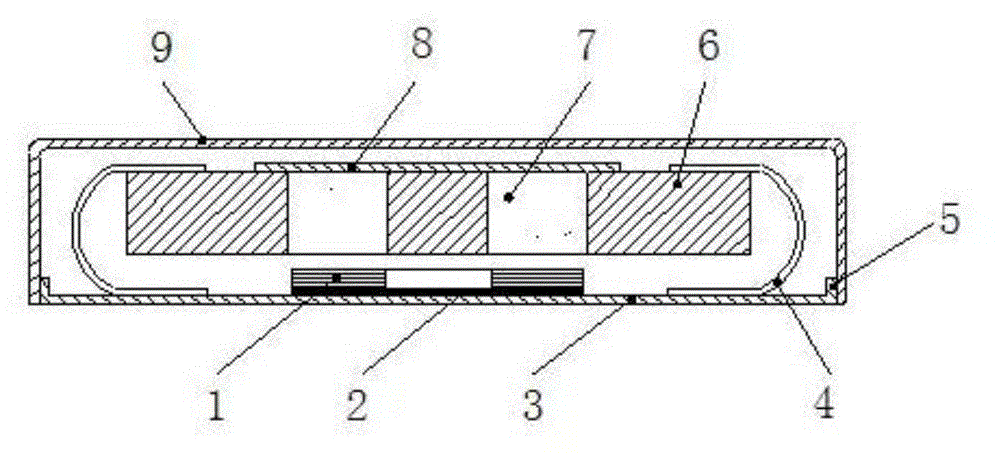

[0027] like figure 1 , figure 2 In the described embodiment, a horizontal vibrating motor includes a lower bracket assembly, a vibrating assembly and an upper casing 9, the lower bracket assembly is provided with several coils 1, and the vibrating assembly includes a spring 4, a vibrating hammer 6 and several magnets. The steel 7 and the magnetic steel 7 are installed on the vibrating hammer 6, the spring 4 is installed on the left and right sides of the vibrating hammer 6, the vibration assembly is installed on the lower bracket assembly through the spring 4, the magnetic steel 7 corresponds to the coil 1, and the upper casing 9 Installed on the lower bracket assembly and covers the entire vibration assembly.

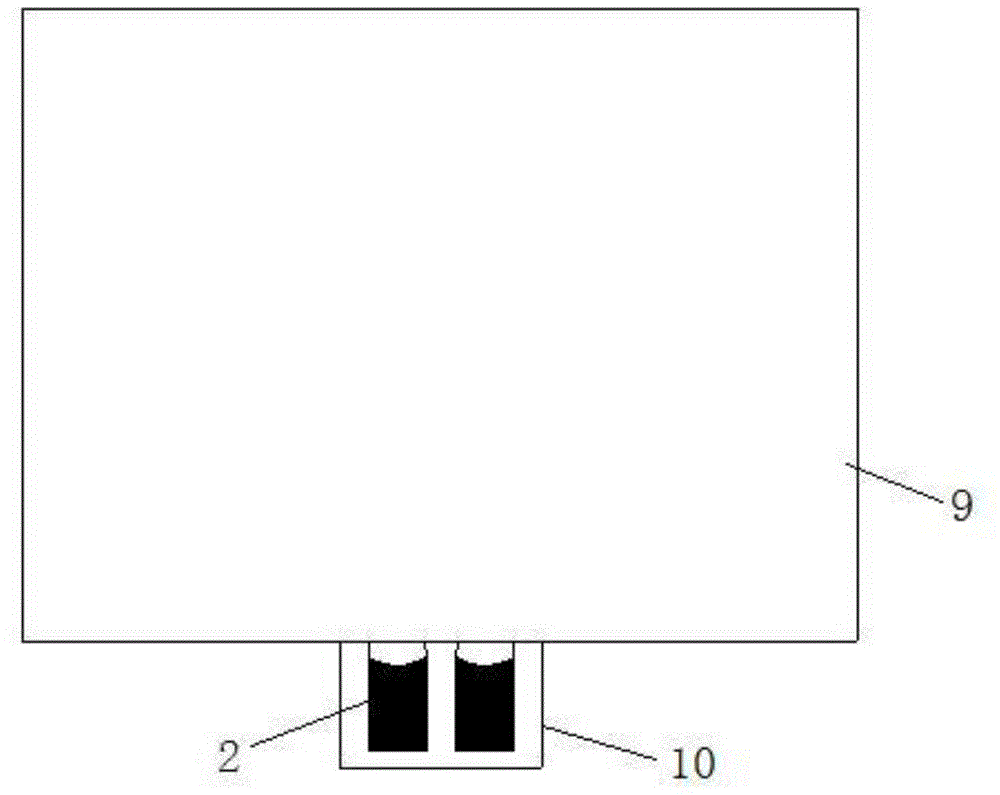

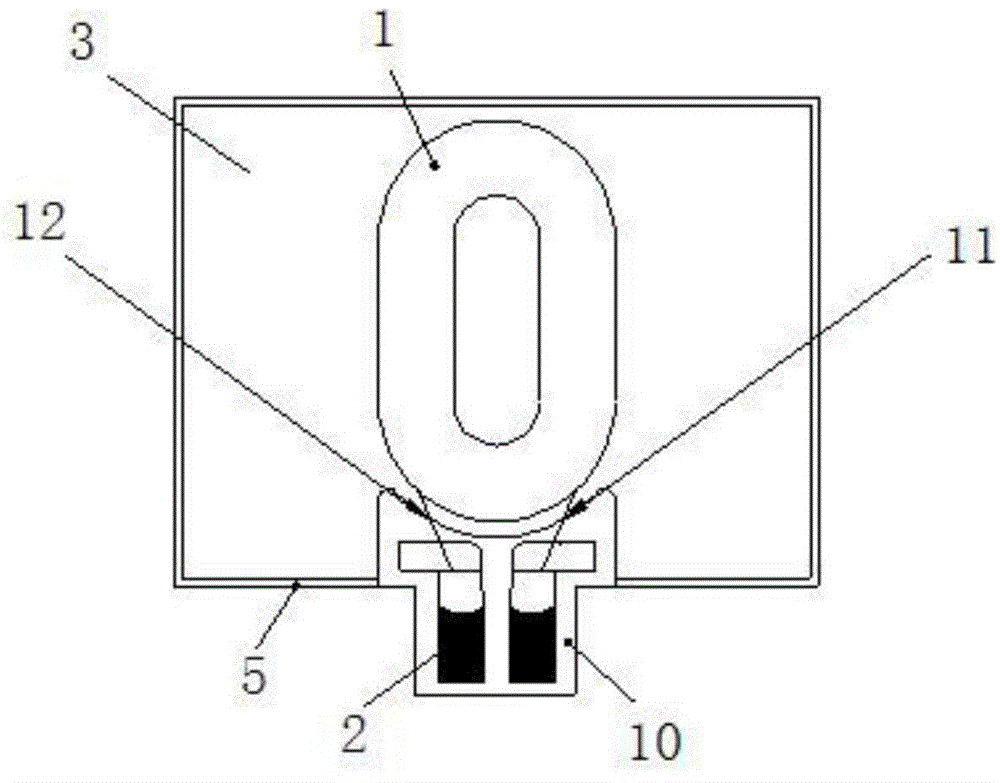

[0028] like image 3 As shown, the lower bracket assembly includes several coils 1, a lower case 3 and FPCB2 (also known as: flexi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com