Artificial electromagnetic material, manufacturing method of artificial electromagnetic material, antenna housing and antenna system

An artificial electromagnetic material, antenna system technology, applied in the direction of antenna, electrical components, radiation unit cover, etc., can solve the problems of monitoring the molding process, disadvantage, easy to cause deviation, etc., to achieve good detection performance, light weight, good use performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The invention relates to a preparation method of an artificial electromagnetic material. Compared with the existing preparation method, the whole preparation process can be better monitored, so that each parameter in the process can be accurately controlled, so that the artificial electromagnetic material finally prepared The material not only ensures good electromagnetic properties, but also has good mechanical properties.

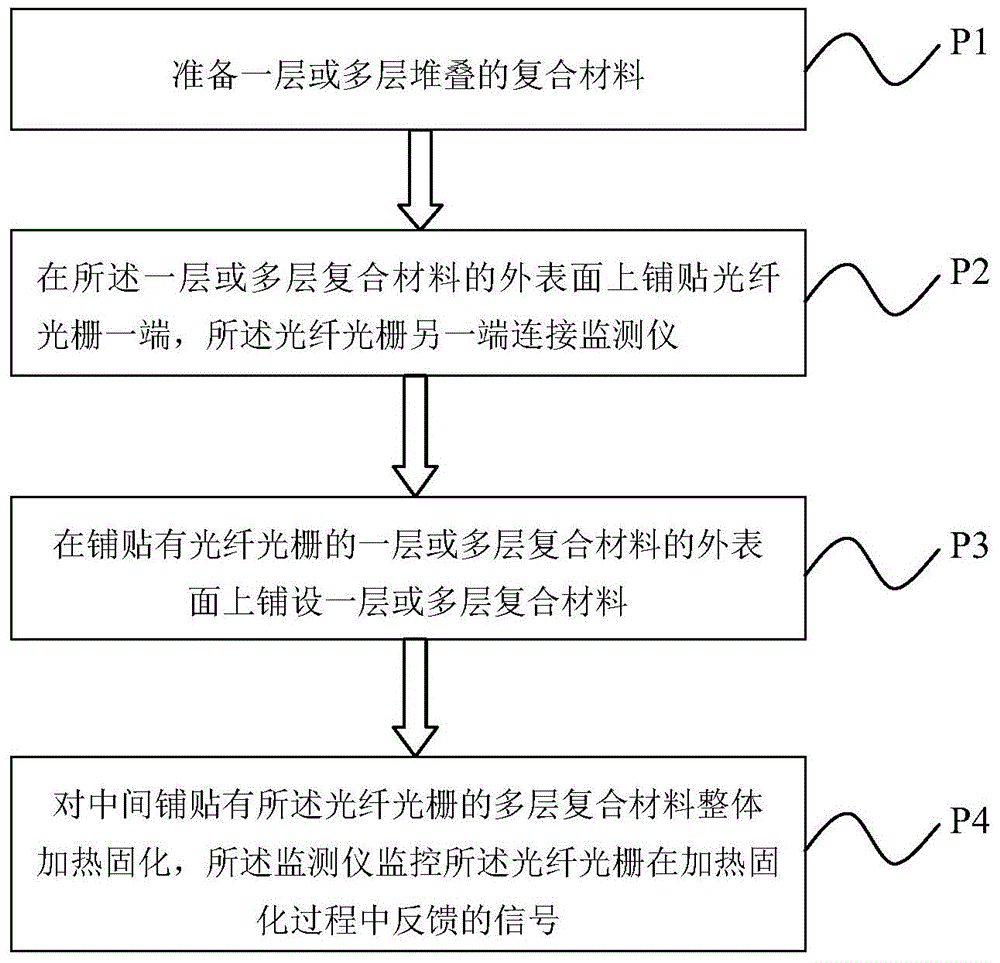

[0047] Specifically, such as figure 1 Shown, the preparation method of a kind of artificial electromagnetic material of the present invention comprises the steps:

[0048] P1. Prepare one or more layers of composite materials;

[0049] P2. Laying one end of the fiber grating on the outer surface of the one or more layers of composite material, and connecting the other end of the fiber grating to a monitor;

[0050] P3. Laying one or more layers of composite materials on the outer surface of the layer or layers of composite materials with fiber gr...

Embodiment 1

[0062] P1. Select composite material as prepreg, and stack five layers of prepreg.

[0063] The prepreg includes a base layer and a plurality of (usually hundreds or thousands of) fibers attached to the base layer, and these fibers are spread across the base layer parallel to each other. Preferably, the five layers of prepregs are placed along the same direction of fibers, which can keep the prepregs from being weakly cured and bonded due to different stress directions during subsequent heating.

[0064] P2. Set the grating ends of multiple fiber gratings on the outer surface of the uppermost prepreg, and the direction of the fiber grating placed on the prepreg is 0 degrees, that is, parallel to the fiber direction of the prepreg setting, which can reduce the error caused by stress changes.

[0065] Of course, it is also allowed that the optical fiber grating crosses the fiber direction at a small acute angle.

[0066] The other end of the fiber grating is connected to a mon...

Embodiment 2

[0073] This embodiment has the same steps as the first embodiment, and the difference from the first embodiment is that in step P2, the fiber grating is pretreated before the operation of disposing the fiber grating on the surface of the prepreg.

[0074] Preprocessing includes the following two steps:

[0075] S21. Verifying the fiber grating;

[0076] S22. Clean the fiber grating after calibration.

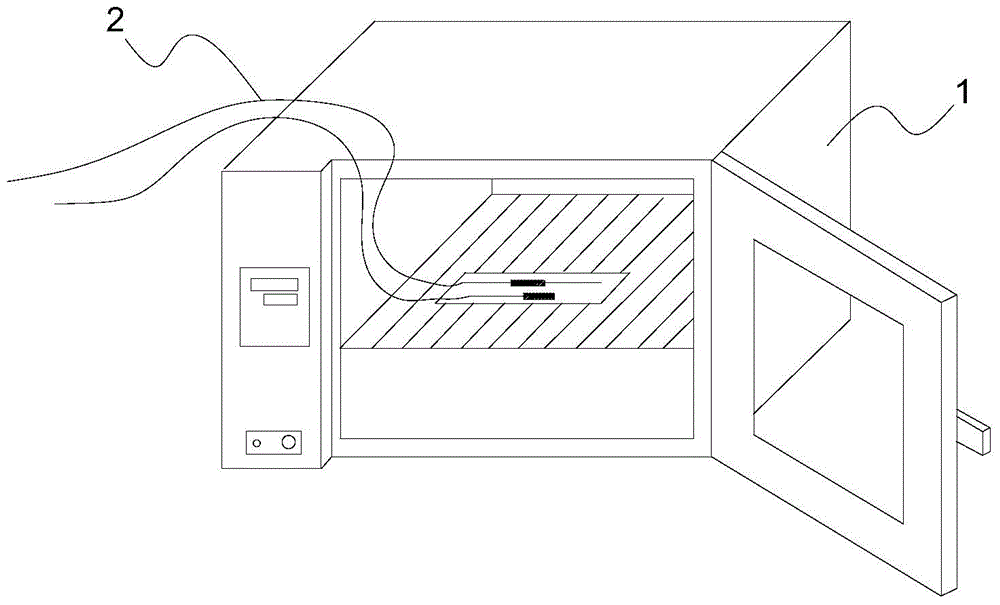

[0077] Wherein, the implementation of step S21 is specifically as follows image 3 As shown, the grating end of the fiber grating 2 is placed in the oil bath heating mechanism 1, and the other end is connected to a monitor, namely a fiber grating demodulator.

[0078] The oil bath heating mechanism 1 heats up the oil at a heating rate of 2 to 3 degrees Celsius per minute, and at the same time turns on the fiber grating demodulator to record in real time the temperature curve fed back by the fiber grating 2 immersed in the oil, and uses computer software to analyze the deviatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com