Battery shell for achieving radiating and safety of lithium core

A battery shell and lithium battery cell technology, applied to large-size batteries/battery packs, small-size batteries/battery packs, secondary batteries, etc., can solve the problem of less heat dissipation channels, over-thick battery shell design, and potential safety hazards and other issues, to achieve the effect of improving heat dissipation performance, increasing surface area, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

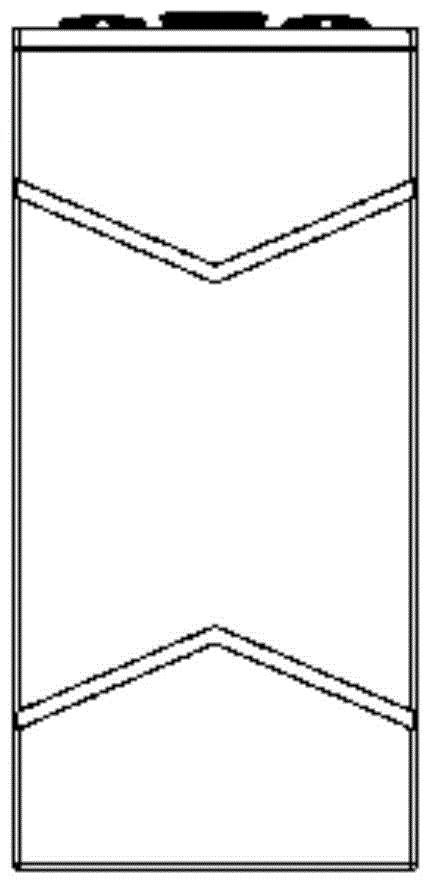

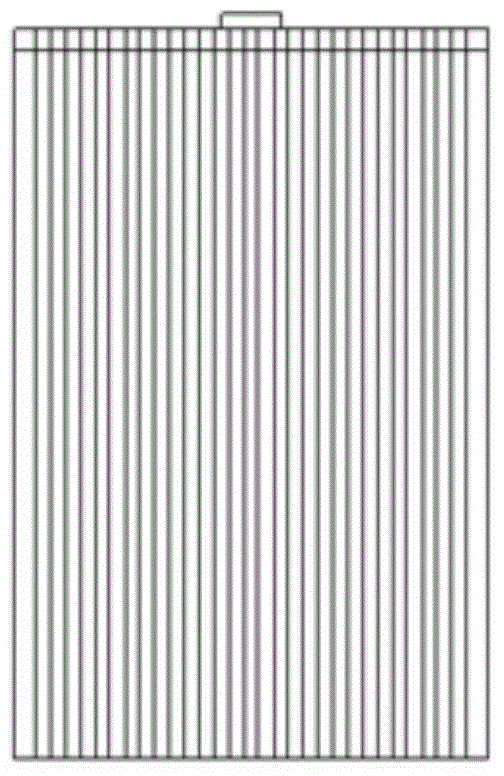

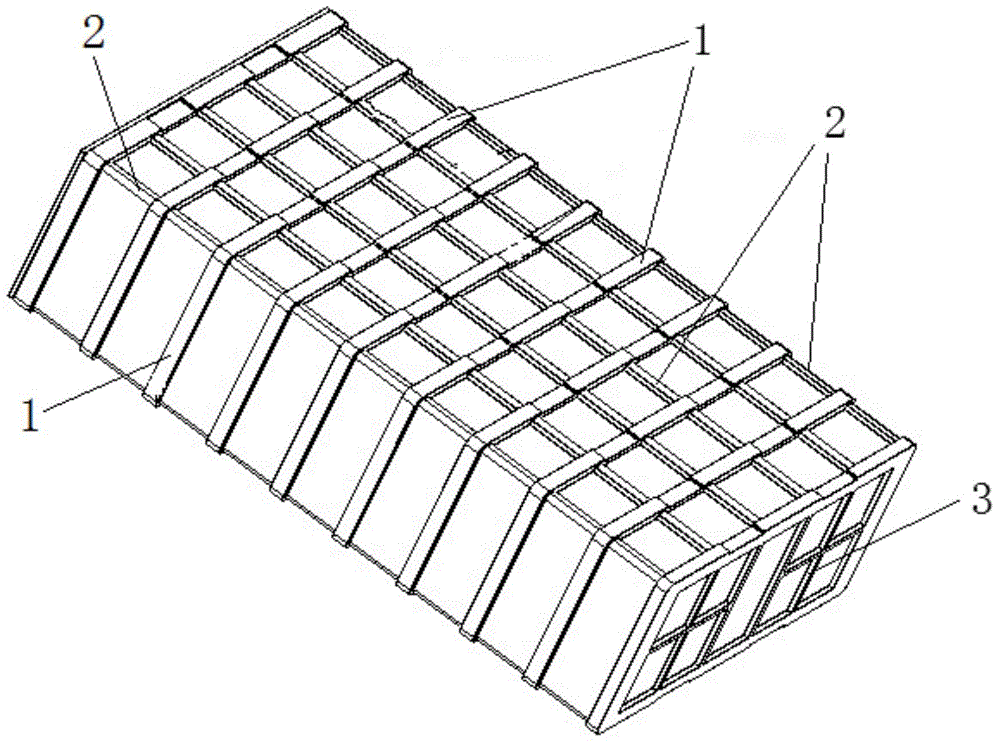

[0037] A battery casing for solving heat dissipation and safety of lithium batteries, the structure of which is as follows Figure 3-7 As shown, it includes the main body of the housing, and an opening for placing the battery is left on the main body of the housing; on the side of the main body of the housing, there are several circles of first heat dissipation protruding edges 1, and each circle of adjacent first heat dissipation protruding edges 1 The second heat dissipation convex edge 2 is arranged in parallel on the side of the shell body along the direction perpendicular to the first heat dissipation convex edge 1; the distance between the first heat dissipation convex edge 1 of each circle and the second heat dissipation convex edge The distance between the edges 2 is set according to the actual situation.

[0038] A number of grooves 4 are provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com