Intelligent self-picking system for tool distribution

A technology for extracting systems and knives, applied to coin-free or similar appliances, coin-operated equipment and instruments for distributing discrete items, etc., can solve the problems of wasting manpower, wasting time, and complicated steps, saving manpower and time. , reducing cross-influence, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

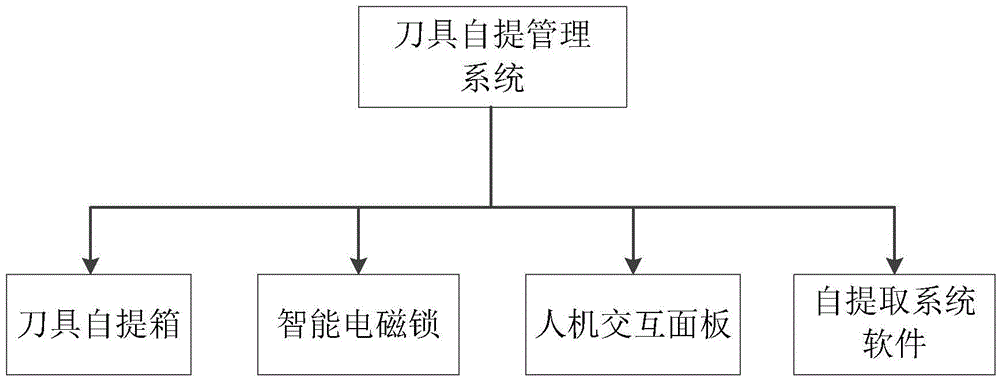

[0011] The intelligent self-pickup system for tool distribution involved in this embodiment is composed of a tool self-pickup box, an intelligent electromagnetic lock, a human-computer interaction panel, and a self-pickup system software, such as figure 1 shown; where:

[0012] (1) The construction of the tool self-collection box. The tool carrying case is composed of multiple units of different sizes, which can be freely selected according to the size of different batches of tools. Tool self-carrying boxes are set in the activity range of each workshop, and the specific location can be determined according to the location of the warehouse and workshop, so that the craftsmen and warehouse staff can reach the effect conveniently. In addition, there is a requirement for the location to have electronic equipment connections such as power systems.

[0013] (2) Intelligent electromagnetic lock. The electromagnetic lock uses the electromagnetic principle. When the current passes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com