A centralized heating temperature control system for pu shoe sole pouring production line

A technology of centralized heating and temperature control system, which is applied in the direction of using electric mode for temperature control, etc., can solve the problems of poor heat preservation of the filter, unbalanced ratio, affecting the accuracy, etc., to achieve good heat dissipation effect, reduce pipe blockage and save money. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

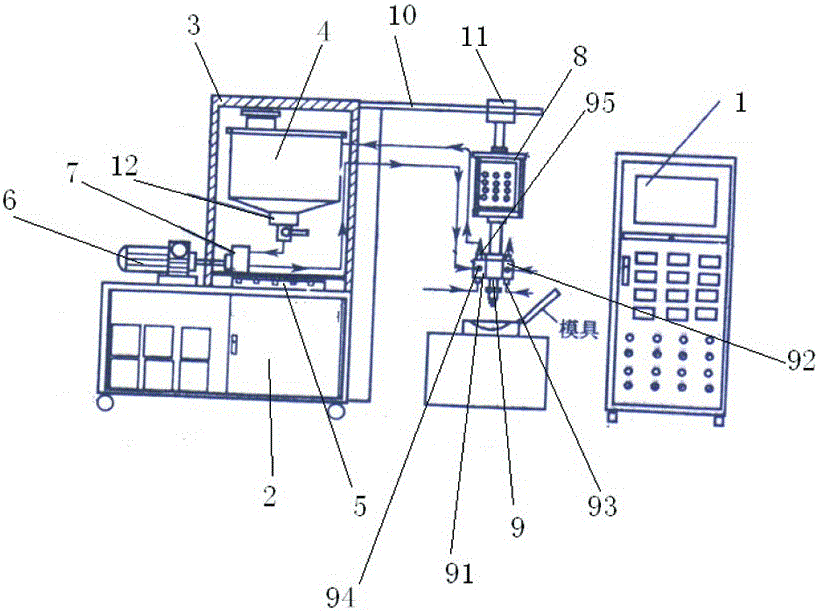

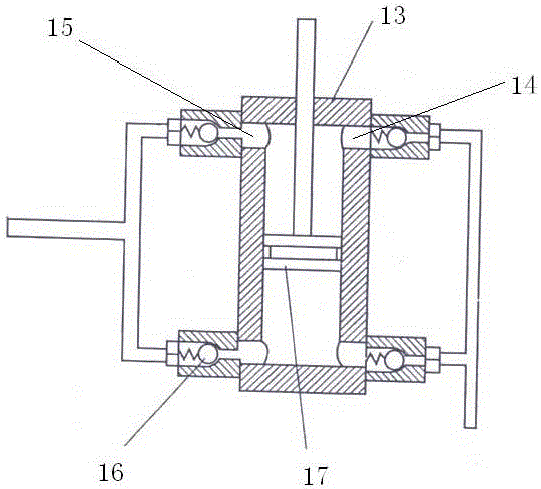

[0016] Example one: such as figure 1 As shown, a centralized heating temperature control system for a PU sole pouring production line includes a computer control cabinet 1 and a raw material oven 2. The raw material oven 2 is equipped with a heating and incubator 3, and the heating and incubator 3 is provided with a barrel 4 in the cavity to heat The bottom of the cavity of the incubator 3 is provided with a heating plate 5. The material in the barrel 4 is conveyed to the temperature control box 8 by a speed-regulating motor 6 driven by a metering pump 7 and a mixing pouring head is provided at the outlet of the temperature control box 8 9. The temperature control box 8 and the speed regulating motor 6 are respectively electrically connected to the computer control cabinet 1. The upper end of the heating and incubator 3 is provided with a sliding bracket 10, the sliding bracket 10 is provided with a rotary valve 11, the temperature control box 8 and the rotary valve 11 connectio...

Embodiment 2

[0021] Embodiment two: such as figure 1 As shown, a centralized heating temperature control system for a PU sole pouring production line includes a computer control cabinet 1 and a raw material oven 2. The raw material oven 2 is equipped with a heating and incubator 3, and the heating and incubator 3 is provided with a barrel 4 in the cavity to heat The bottom of the cavity of the incubator 3 is provided with a heating plate 5. The material in the barrel 4 is conveyed to the temperature control box 8 by a speed-regulating motor 6 driven by a metering pump 7 and a mixing pouring head is provided at the outlet of the temperature control box 8 9. The temperature control box 8 and the speed regulating motor 6 are respectively electrically connected to the computer control cabinet 1. The upper end of the heating and incubator 3 is provided with a sliding bracket 10, the sliding bracket 10 is provided with a rotary valve 11, the temperature control box 8 and the rotary valve 11 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com