A kind of assay method of dbd content in rubber chemical peptizer

A determination method and peptizer technology, applied in measuring devices, scientific instruments, instruments, etc., can solve the problem that there is no literature report on the determination of DBD content in the main body of peptizer, and achieve simple, easy and reproducible processing. Good, short analysis time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

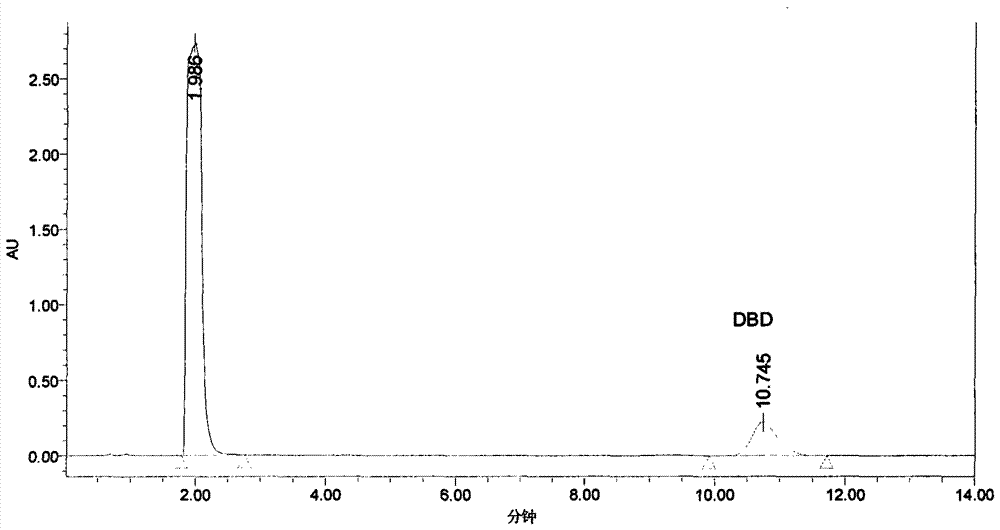

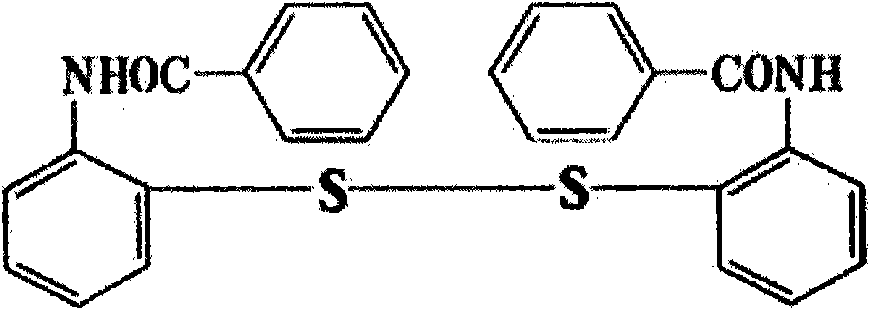

[0047] Embodiment 1: the analysis of DBD content in the known chemical peptizer product

[0048] (1) Sample preparation: Weigh 26.45mg, 29.36mg, and 27.82mg of known chemical peptizer products (DBD theoretical content 40%) respectively, as three parallel samples, accurate to 0.1mg, and put them into a 50mL volumetric flask , add 40mL acetone to dissolve and sonicate for 10min, after standing still for 30min, dilute the volume of acetone to the mark. Shake the volumetric flask to mix the solution evenly, pipette part of the solution with a 2ml syringe, filter it with a 0.45 μm filter membrane, and then enter the filtrate into a high-performance liquid chromatograph for testing.

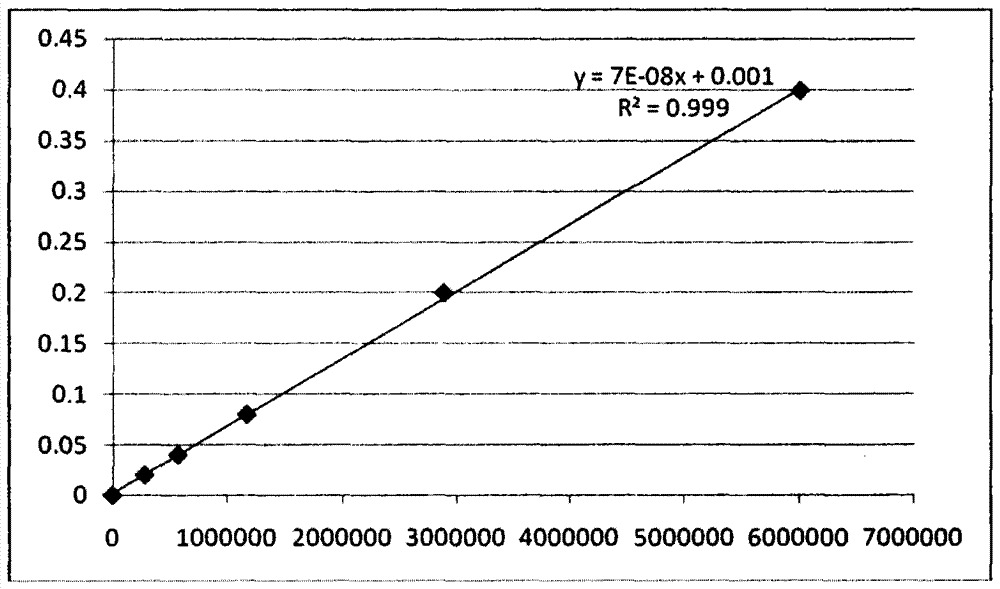

[0049] (2) Preparation of standard solution: Take 39.9mg of DBD standard substance, accurate to 0.1mg, put it into a 100mL volumetric flask, dissolve it with acetone and set the volume to the mark. Use a 5mL pipette to pipette 5mL of DBD mother liquor to a 10mL volumetric flask, take a 1mL pipette to ...

Embodiment 2

[0064] Embodiment 2: the analysis of DBD content in the chemical peptizer product Renacit 11

[0065] (1) Sample preparation: Weigh 30.0mg of chemical peptizer product, accurate to 0.1mg, put it into a 50mL volumetric flask, add 30mL of methanol to dissolve and ultrasonicate for 30min, after standing for 30min, dilute the methanol to the scale line . Shake the volumetric flask to mix the solution evenly, pipette part of the solution with a 2ml syringe, filter it with a 0.45 μm filter membrane, and test the filtrate with a high performance liquid chromatograph.

[0066] (2) Preparation of standard solution: Take 34.1mg of DBD standard substance, accurate to 0.1mg, put it into a 100mL volumetric flask, dissolve it with methanol and set the volume to the mark. Use a 5mL pipette to pipette 5mL of the DBD mother liquor to a 10mL volumetric flask, take a 1mL pipette to pipette 1mL of the mother liquor to the 5mL and 10mL volumetric flasks, and then use a 1mL pipette to pipette 0.50...

Embodiment 3

[0071] Embodiment 3: Analysis of DBD content in the chemical peptizer product Renacit 11

[0072] (1) Sample preparation: Weigh 30.5mg of chemical peptizer product, accurate to 0.1mg, put it into a 50mL volumetric flask, add 40mL of acetonitrile to dissolve and sonicate for 30min, after standing for 30min, dilute acetonitrile to the scale line . Shake the volumetric flask to mix the solution evenly, pipette part of the solution with a 2ml syringe, filter it with a 0.45 μm filter membrane, and then enter the filtrate into a high-performance liquid chromatograph for testing.

[0073] (2) Preparation of standard solution: Take 33.2mg of DBD standard substance, accurate to 0.1mg, put it into a 100mL volumetric flask, dissolve it with acetonitrile and set the volume to the mark. After filtering with a 0.45 μm filter membrane, enter the high-performance liquid chromatograph for testing.

[0074] (3) Test conditions: Waters 2996 diode array detector, detection wavelength 254nm; Wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com