Semi-rigid base asphalt pavement reflection crack testing device

A semi-rigid base and test device technology, which is applied in measurement devices, strength characteristics, instruments, etc., can solve the problems of unpredictable generation timing and generation location, difficult for researchers to observe, etc., and achieves easy operation, reliable method, and simulated test mechanism. clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention is described in further detail:

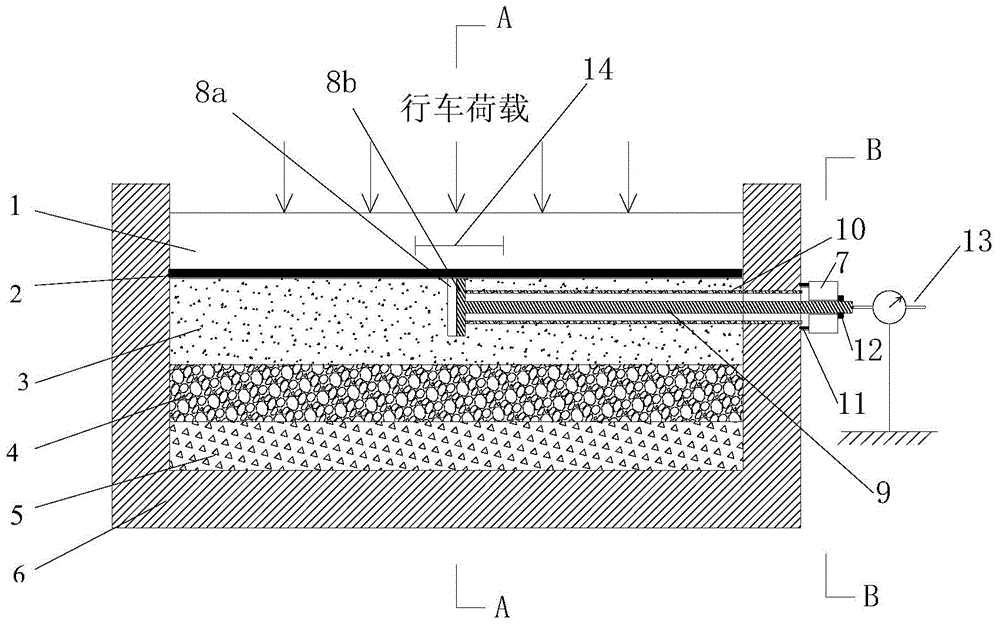

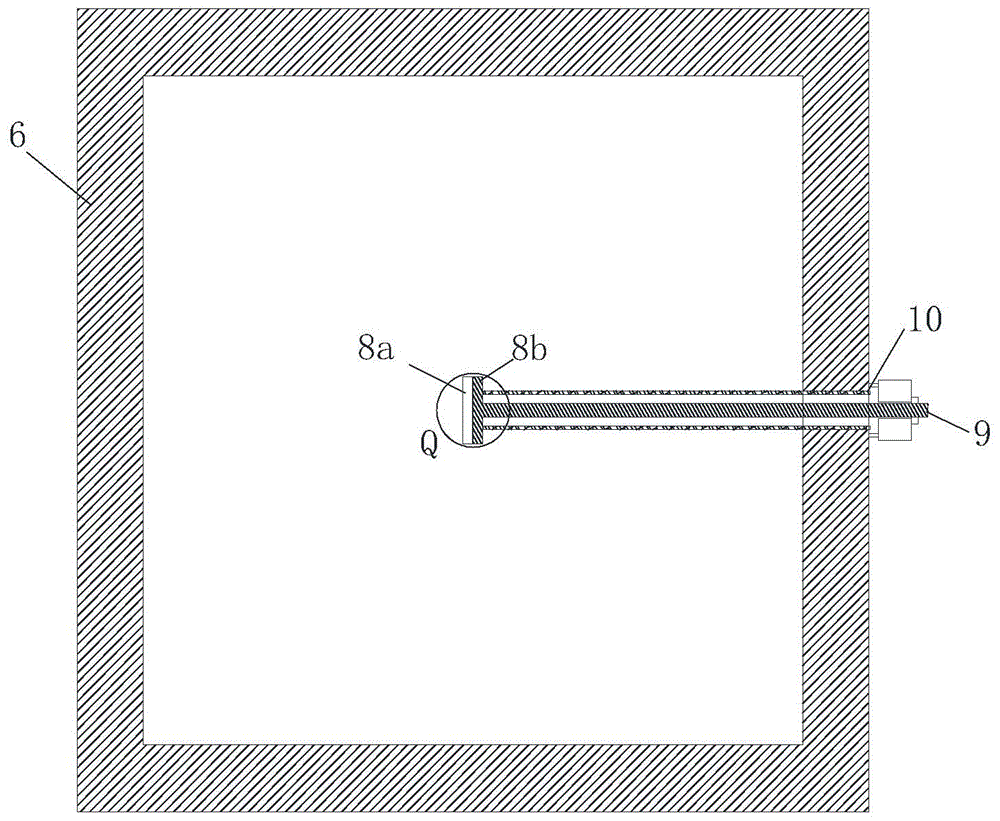

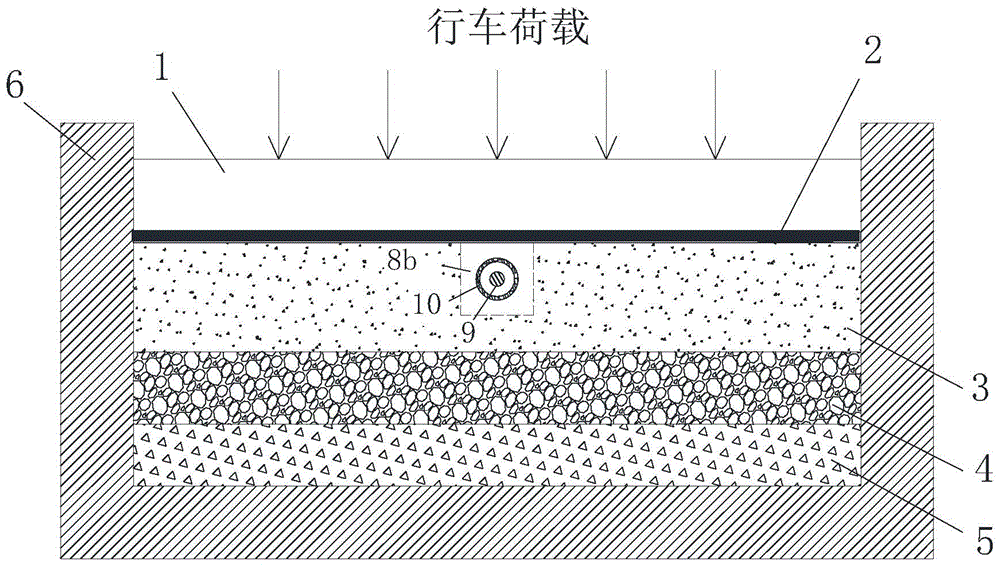

[0031] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 It can be seen that a test device for reflective cracking of semi-rigid base asphalt pavement is composed of surface layer 1, sealing layer 2, semi-rigid base layer 3, sub-base layer 4, soil foundation 5, steel channel 6, hollow hydraulic jack 7, first steel plate 8a, a second steel plate 8b, a dowel bar 9, a steel pipe 10, a bolt 11, a nut 12, a displacement sensor 13, and a crack gauge 14. It is characterized in that the soil foundation 5, subbase 4, semi-rigid base 3, seal 2 and surface 1 are filled in the steel channel 6 from bottom to top in sequence, and the first steel plate 8a and the second steel plate 8b are vertically pre-embedded in the semi-rigid In the rigid base 3, the steel pipe 10 is pre-embedded horizontally in the semi-rigid base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com