Temperature testing method for solar battery layer laminating machine

A technology of solar cells and test methods, applied in the direction of thermometers that give differences, can solve the problems of lamination temperature and its curve easily distorted, hidden dangers of product reliability, scalding of hot plate of laminating machine, etc., to avoid product reliability. Reduced sexuality, clear history, and ease of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

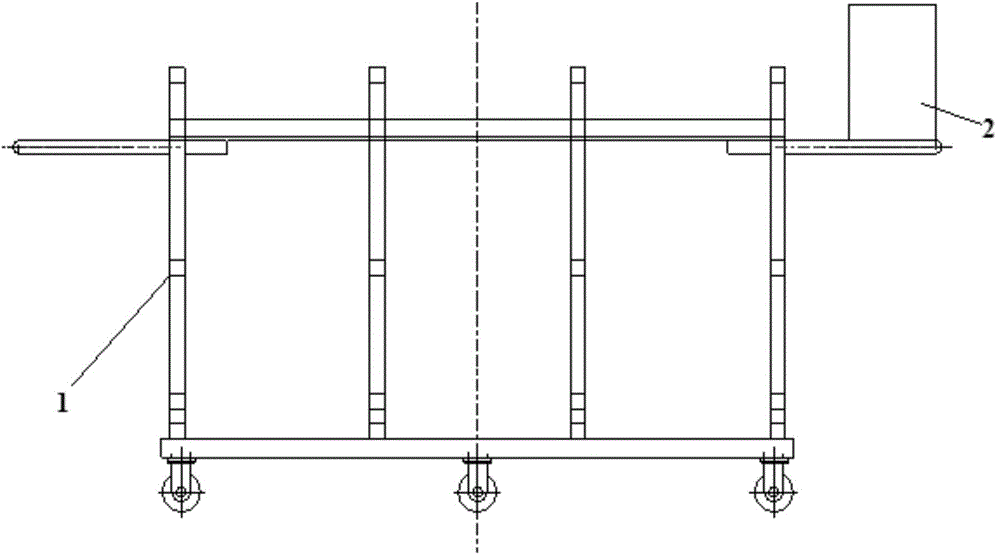

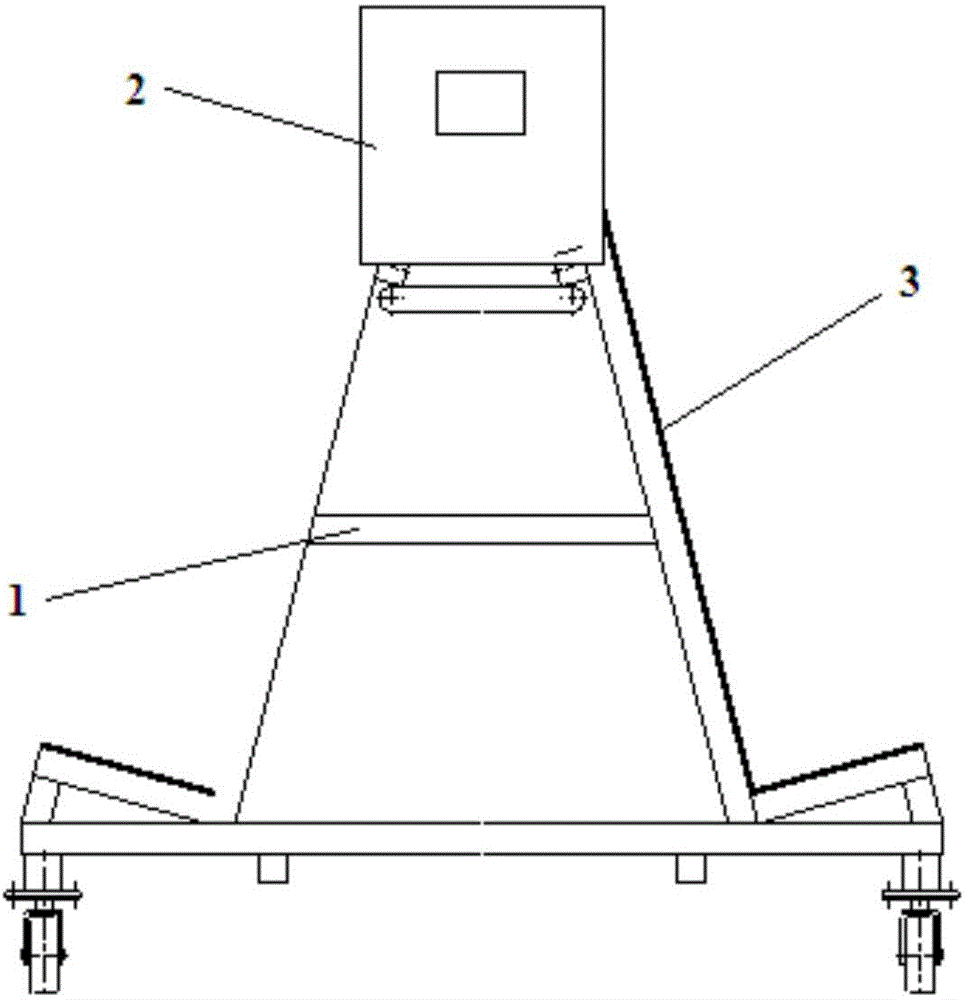

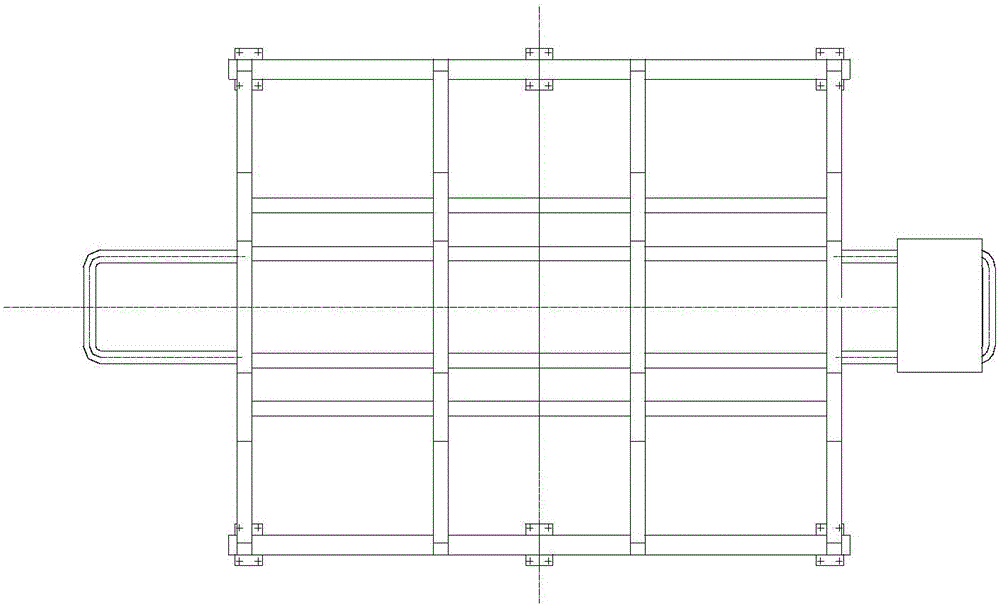

[0030] Such as Figure 1-3 Shown, a kind of solar cell laminator temperature testing method comprises the following steps:

[0031] 1) Place the simulated test board 3 with the embedded temperature sensor on the feeding plate 1 of the laminator, and perform pressing according to normal lamination production;

[0032] 2) The temperature sensor transmits the measured temperature information to the control box 2;

[0033] 3) The temperature obtained by the control box 2 is displayed in real time through the monitor, and the temperature uniformity and temperature stability test is carried out.

[0034] There are 4 simulation test boards 3, and 4 temperature sensors are pre-embedded in each simulation test board 3.

[0035] In the temperature uniformity test, the test is started after the temperature of the laminator reaches the set temperature and stabilizes for a set time, or after the cover is laminated, and the highest temperature value and the lowest temperature value are se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com