A kind of fixing method of nuclear grade swing check valve disc

A fixed method, swing-type technology, applied in the direction of control valves, valve devices, functional valve types, etc., can solve problems such as no public reports, and achieve the effect of promoting localization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

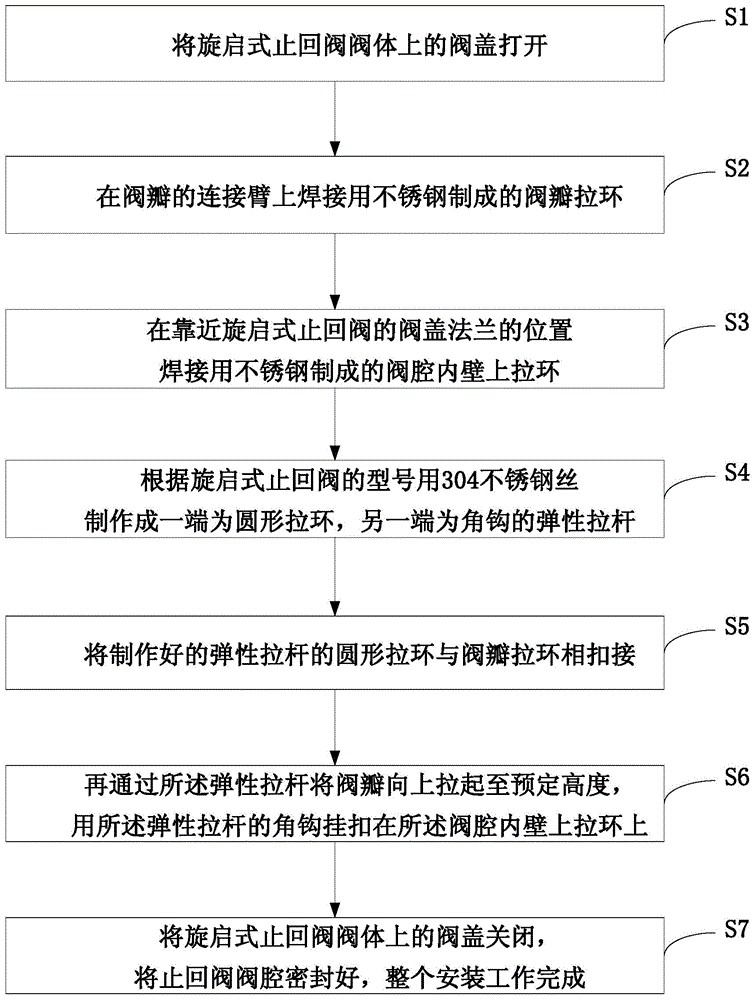

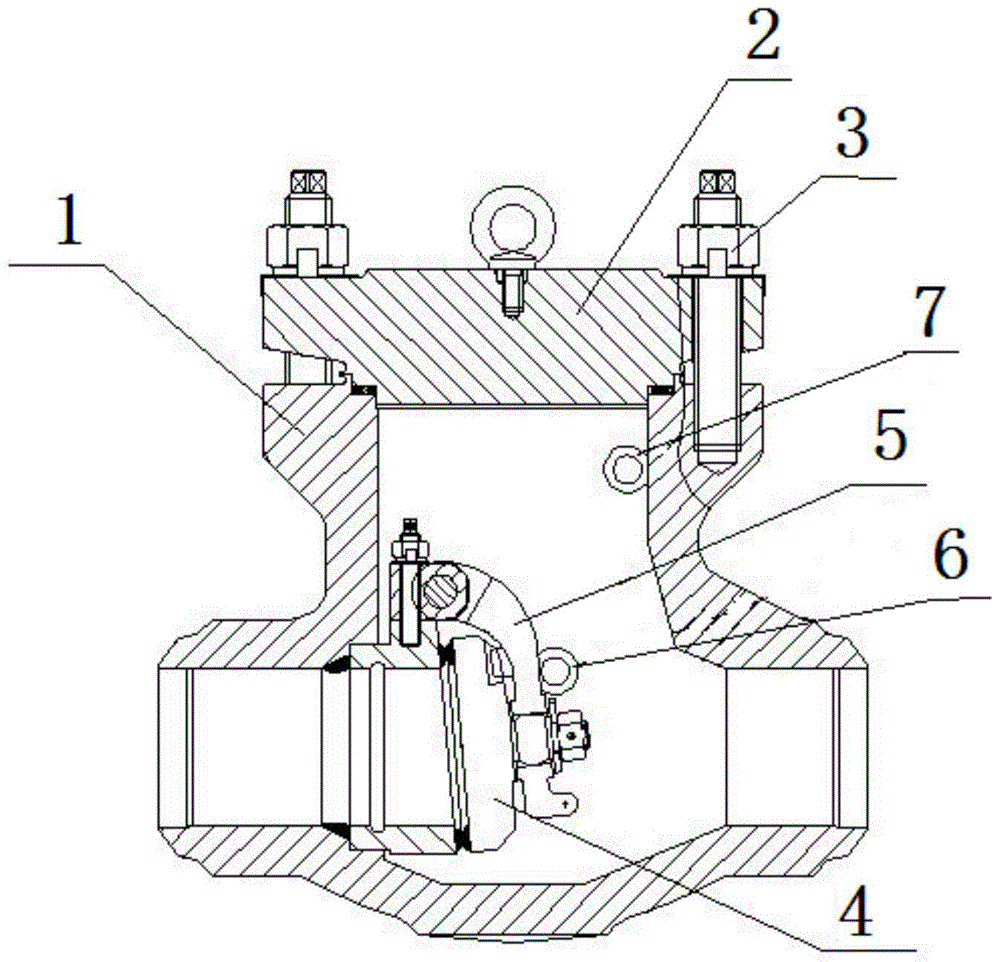

[0019] In order to further understand the technical content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

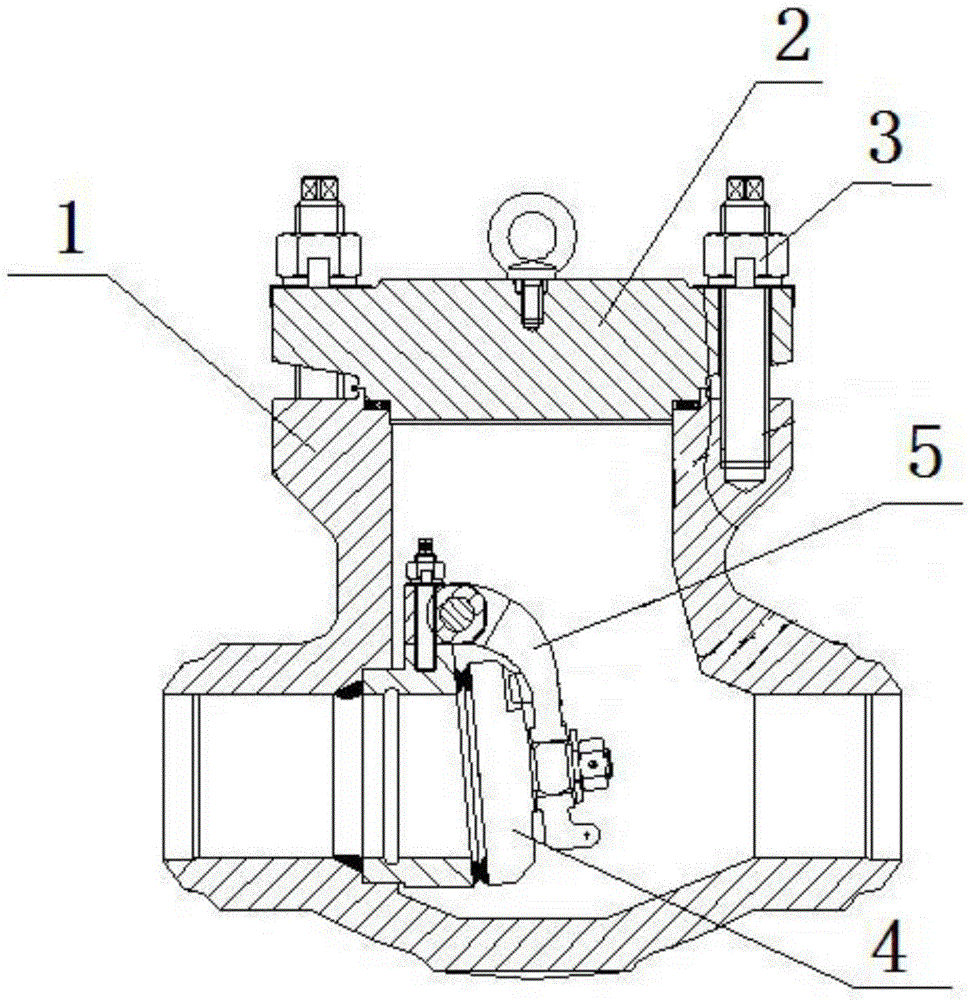

[0020] In the reverse flow test of the functional qualification test of the nuclear grade swing check valve, to establish the static reverse flow test condition of the check valve, an auxiliary technical condition that needs to be met is: the disc of the swing check valve needs to be designed Fix the fall-off mechanism. This mechanism should have the function of making the valve disc of the check valve in the lifting and opening state before the test, and the valve disc will fall off automatically under the impact of the fluid during the test, so that the check valve can be quickly closed.

[0021] The conditions for designing the fixed and falling mechanism of the check valve disc are: (1) the mechanism can fix the disc of the swing check valve at any opening position; (2) when the check val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com