Tamping coke oven tamping hammer fiction piece local bonding method

A technology for tamping coke ovens and bonding methods, applied in coke ovens, connecting components, petroleum industry, etc., can solve the problems of affecting the bonding strength of friction plates, time-consuming, labor-intensive, and labor-intensive, and achieve good bonding effect. , High efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

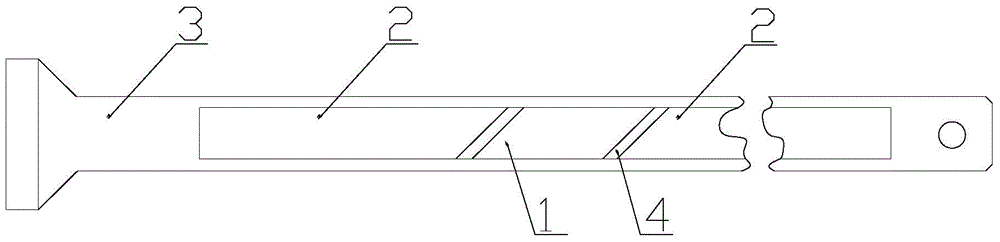

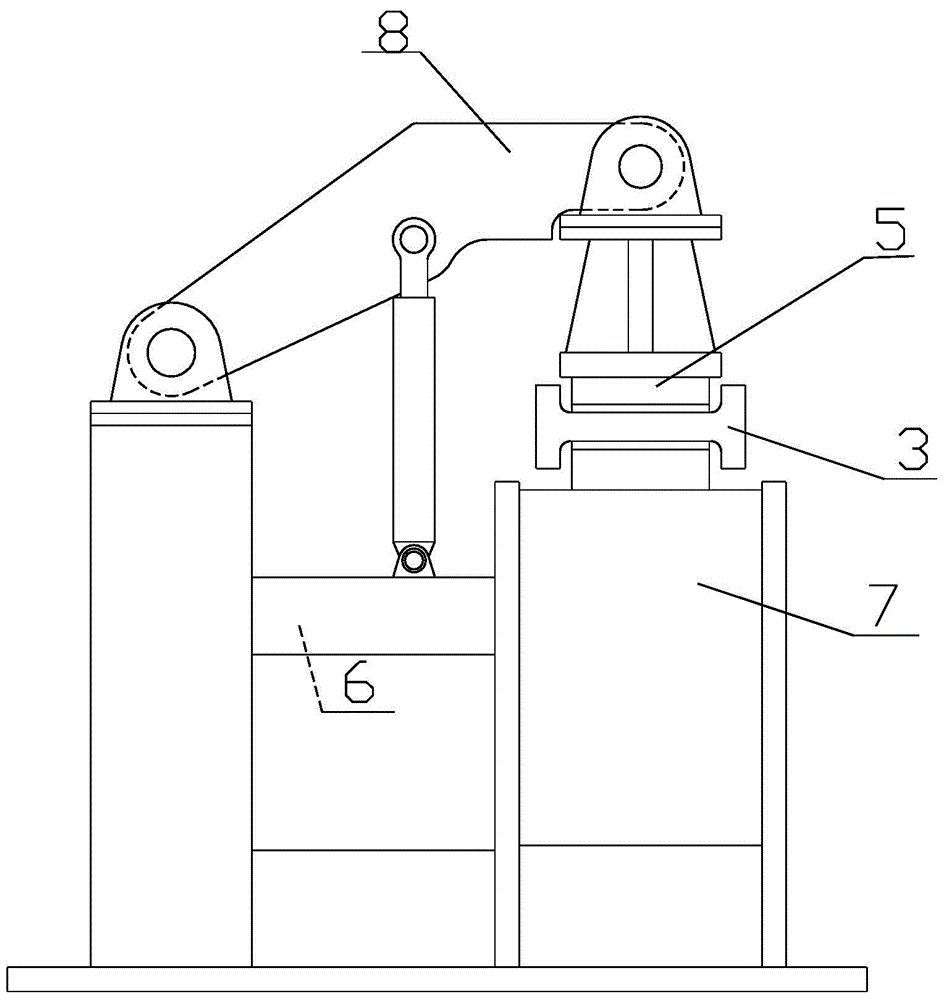

[0025] Example 1: Operate according to the above steps, use the adhesive material with a volume ratio of adhesive and curing agent of 1:1, mix the adhesive and curing agent evenly, and bond the new friction sheet 1 with the old friction sheet 2 The gap 4 between them is 3mm, the setting pressure of the accumulator of the bonding machine is 8MPa, and the pressure duration is 6 hours. The service life of the brand-new tamping hammer friction plate is about 1 to 1.5 years, and the service life of the friction plate bonded in this embodiment is about 0.5 years.

Embodiment 2

[0026] Example 2: Operate according to the above steps, use the adhesive material with a volume ratio of adhesive and curing agent of 1:1, mix the adhesive and curing agent evenly, and bond the new friction sheet 1 with the old friction sheet 2 The gap 4 between them is 3mm, the setting pressure of the accumulator of the bonding machine is 10.5MPa, and the pressure duration is 4 hours. The service life of the friction plate after bonding in this embodiment is about 0.8 years.

Embodiment 3

[0027] Example 3: Operate according to the above steps, use the adhesive material with a volume ratio of adhesive and curing agent of 1:1, mix the adhesive and curing agent evenly, and bond the new friction sheet 1 with the old friction sheet 2 The gap 4 between them is 3mm, the setting pressure of the accumulator of the bonding machine is 10.7MPa, and the pressure duration is 4 hours. The service life of the friction plate after bonding in this embodiment is about 0.8 years.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com