A test platform for energy conversion unit

A technology of energy conversion and energy conversion, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, mechanical equipment, etc. It can solve the problems that the performance of the pump side and the motor side of the energy conversion unit cannot be tested at the same time, and achieves convenient disassembly. Easy to install, easy to test, and prevent air suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

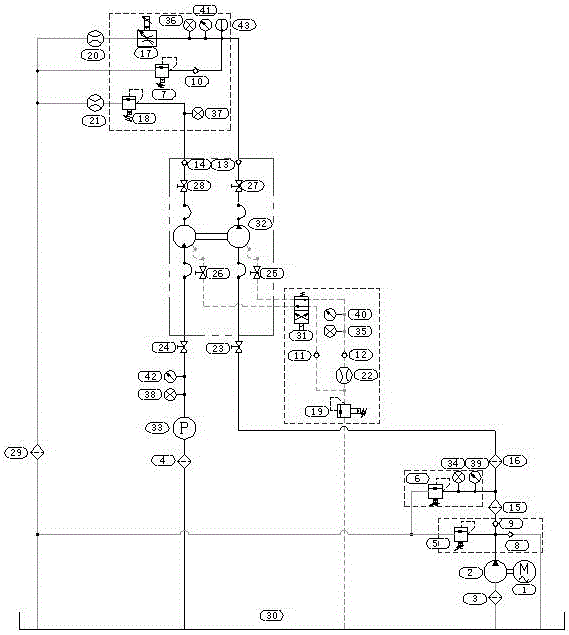

[0009] A test platform for energy conversion unit, including: hydraulic oil tank 30, proportional speed regulating valve 17, check valve A8, check valve B9, check valve C10, check valve D11, check valve E12, check valve Valve F13, check valve G14, pressure gauge A39, pressure gauge B40, pressure gauge C41, pressure gauge D42, pressure sensor A34, pressure sensor B35, pressure sensor C36, pressure sensor D37, pressure sensor E38, temperature sensor 43, flow meter A20, flow meter B21, flow meter C22, oil suction oil filter A3, oil suction oil filter B4, oil return oil filter 29, high pressure oil filter A15, high pressure oil filter B16, also includes the measured energy conversion unit 32, external pump station 33, Back pressure valve A18, back pressure valve B19, AC motor 1, booster oil pump 2, relief valve A5, relief valve B6, relief valve C7, two-position four-way reversing valve 31, manual ball valve A23, manual ball valve B24 , Manual ball valve C25, manual ball valve D26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com