Large-flux oil suction filter capable of automatically alarming and relieving pressure

An oil-absorbing filter and automatic alarm technology, which is applied to rotary piston/oscillating piston pump components, machines/engines, pump components, etc., can solve the problem that the quenching quality of products cannot meet the requirements and frequent failures of high-flow screw pumps , filter oil suction port blockage and other problems, to achieve the effect of convenient production, reduce safety hazards, and avoid air suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

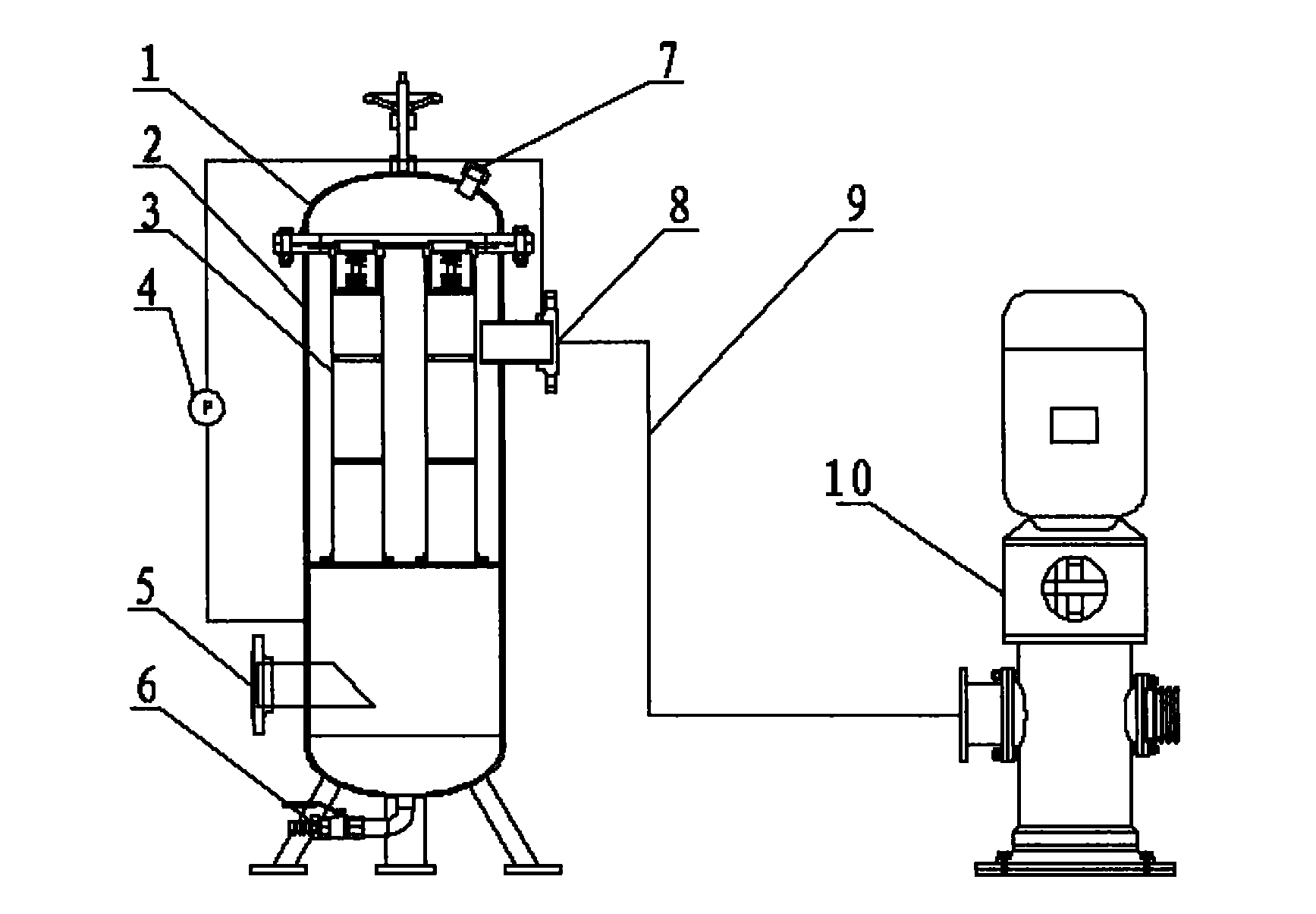

[0014] Such as figure 1 As shown, a large-flow oil-absorbing filter capable of automatic alarm and pressure release includes an inspection cover 1, a cylinder body 2, a filter element assembly 3, a differential pressure alarm switch 4, an oil inlet 5, a sewage outlet 6, a pressure relief port 7, Oil outlet 8 oil delivery pipe 9, screw pump 10, the barrel 2 is cylindrical, the top of the barrel 2 is fixed with an inspection cover 1, the bottom of the barrel 2 is fixed with an oil inlet 5, and the bottom of the barrel 2 is fixed with a sewage discharge port. Port 6; the maintenance cover 1 is hemispherical, and the surface of the maintenance cover 1 is fixed with a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com